Description

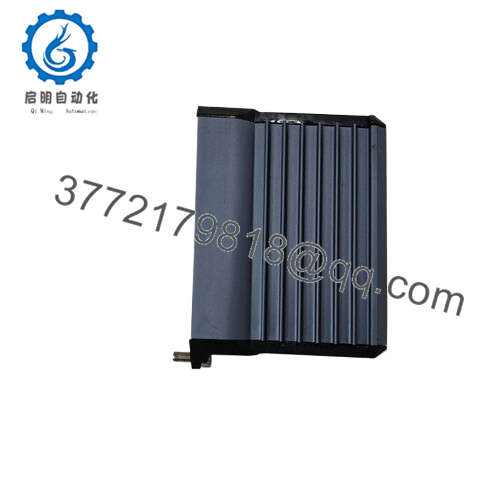

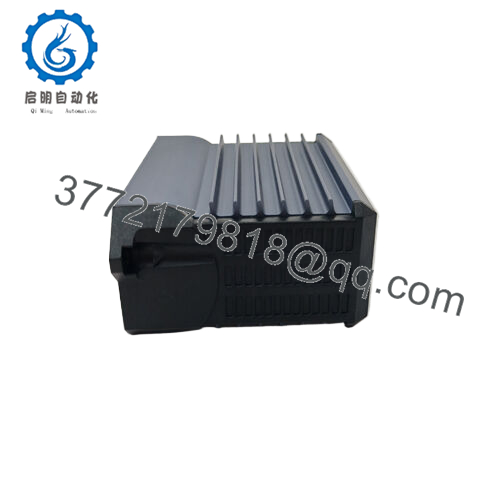

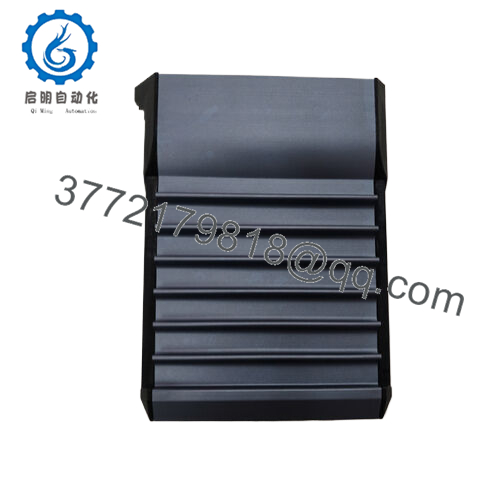

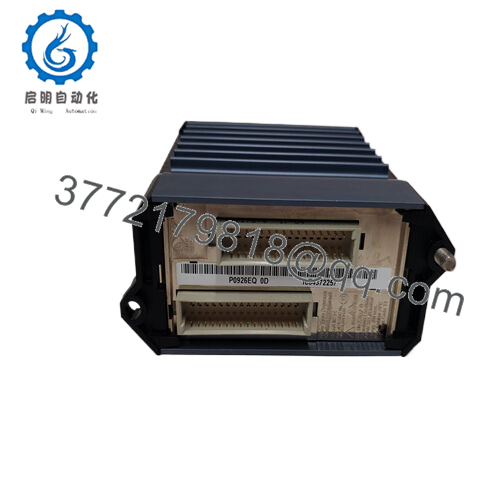

FOXBORO FBM202 P0926EQ is an 8-channel thermocouple/millivolt input interface module and an important component of the Foxboro I/A series. The I/A series is a well-known distributed control system (DCS) in the field of industrial automation, known for its reliability and flexibility. As an input module, FOXBORO FBM202 P0926EQ is a key link between on-site sensors (such as thermocouples) and the central control system in the DCS architecture.

FBM202 P0926EQ

This module is designed to receive and process thermocouple and millivolt signals from the field. All eight channels are electrically isolated, which means that electrical interference between channels is minimized. In industrial environments, there are often multiple electrical signals and potential sources of interference, and this isolation is crucial. The module also has an isolated RTD reference junction compensation channel for terminal temperature sensing, which is crucial for accurate temperature measurement using thermocouples.

FBM202 P0926EQ

Main features and advantages:

FOXBOROFBM202 P0926EQ provides a reliable and efficient solution for temperature related signal acquisition. Its compatibility with the Foxboro I/A series ecosystem enables seamless integration with other components in the series, such as controllers and workstations. This easy to integrate feature simplifies the design and implementation of industrial control systems, saving time and resources.

One of the most prominent features of FOXBORO FBM202 P0926EQ is its high-precision signal processing. It adopts sigma delta data conversion for each channel, which can achieve high accuracy in measuring thermocouple and millivolt signals. This accuracy is crucial, especially in applications such as chemical reactions or power generation processes, where even small deviations in temperature measurements can have significant consequences. By using this module, engineers can have confidence in the reliability of temperature data input into the control system.

In terms of hardware design, FOXBORO FBM202 P0926EQ can withstand harsh industrial environments. Its sturdy structure can withstand extreme temperatures, high humidity, and electrical interference, making it suitable for installation in factories, refineries, and other industrial sites where operating conditions can be extremely challenging. Its compact size also facilitates integration into existing control cabinets, reducing space requirements.

Another advantage of this module is its ability to handle multiple input signals. Each thermocouple/millivolt channel can accept standard thermocouples suitable for various temperature ranges. In addition, it also provides thermocouple burnout detection (upward offset). This feature is very useful because it can quickly alert operators when a thermocouple malfunctions, allowing for timely maintenance and preventing potential process interruptions.

In terms of long-term reliability, FOXBORO FBM202 P0926EQ has built-in diagnostic functions. It can continuously monitor its own performance and detect any potential issues, such as signal loss or hardware failure. By providing early warning, operators can take proactive maintenance measures to reduce the risk of unexpected downtime. Regular firmware updates can also be provided to keep the module in the latest technological state, further improving its long-term reliability.

FBM202 P0926EQ

Technical specifications:

Model FBM202 P0926EQ

Brand FOXBORO

Type 8-channel thermocouple/millivolt input interface module

Power supply 24V DC (+5%, -10%)

Working temperature -20 ° C to 70 ° C

Installation method suitable for DIN rail installation

8 thermocouples/millivolt input channels for input channels

One isolated RTD reference junction compensation channel

Input range -10.5 to+69.5 mV DC (-10.5 to+69.5 mV DC equals 0 to 64000 raw count values). Input 71.419 mV equals 65535 raw count value (module full-scale)

Channel isolation: Each input channel is electrically isolated from other channels and ground

Burn detection provides thermocouple burn detection (upward offset)

Signal conversion uses sigma delta data conversion for each channel

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

FBM202 P0926EQ

Application areas:

In pharmaceutical production factories, drug synthesis typically requires maintaining reaction temperatures within a specific and narrow range. FOXBORO FBM202 P0926EQ can accurately read thermocouple signals, monitor the temperature of the reactor in real time, ensure that chemical reactions proceed as expected, and ultimately guarantee the quality and consistency of drugs.

The power production industry also heavily relies on FOXBORO FBM202 P0926EQ. In coal-fired power plants, it is necessary to closely monitor and control the combustion process. Temperature is a key parameter as it affects power generation efficiency and the environmental impact of power plants. This module can be connected to thermocouples located throughout the boiler, furnace, and exhaust system. By processing the thermocouple and millivolt signals, it provides accurate temperature data to operators, enabling them to adjust the fuel air ratio, optimize the combustion process, and reduce emissions.

In the food and beverage industry, FOXBORO FBM202 P0926EQ helps maintain product quality.

In dairy processing plants, pasteurization is a crucial step in ensuring the safety and shelf life of milk products. This module helps to accurately control the pasteurization temperature, detect any deviation outside the temperature setting range, and send a signal to the control system, which can then adjust the heating or cooling device. This not only ensures that milk is properly pasteurized, but also prevents excessive or insufficient processing, thereby avoiding affecting the taste and nutritional value of the product.

FBM202 P0926EQ

Related products:

FOXBORO FBM201 (P0914SQ) – This is a related fieldbus module. It can be used in conjunction with FOXBORO FBM202 P0926EQ to expand the overall input/output capabilities of the system. For example, FBM202 focuses on thermocouples and millivolt inputs, while FBM201 can process other types of signals to build a more comprehensive data acquisition and control system.

FOXBORO FBM203- Complementary to FOXBORO FBM202 P0926EQ, FBM203 provides additional features. It may be used to process different types of analog or digital signals in the same industrial control setting, working in conjunction with FBM202 to optimize overall signal processing within the system.

FOXBORO FBI10E (P0972AJ) – When integrated with FOXBORO FBM202 P0926EQ, this module enhances communication capabilities within industrial control networks. It can achieve better data transmission between FBM202 and other components within the system, ensuring seamless communication for efficient process control.

FOXBORO CP60 (P0961FR) – This is a control processor module that can be paired with FOXBORO FBM202 P0926EQ to more effectively manage and execute control strategies. CP60 can use temperature data collected by FBM202 to make decisions and control various industrial processes.

FOXBORO CP40B/CP40- These modules are suitable for use with FOXBORO FBM202 P0926EQ in small-scale industrial control applications. They provide basic control functions while maintaining compatibility with FBM202, providing an economical and efficient solution for less complex settings.

FOXBORO CP30B/CP30- Similar to the CP40 series, CP30B and CP30 can be integrated with FOXBORO FBM202 P0926EQ for applications that require cost-effective and reliable control solutions. They can collaborate with FBM202 to provide basic but reliable control functions for industrial processes.

FOXBORO RTD Input Modules (such as FBM217) – When the system requires simultaneous thermocouple and RTD temperature measurement, these RTD input modules can work in parallel with FOXBORO FBM202 P0926EQ. They collectively provide a more comprehensive view of temperature conditions in industrial processes.

FBM202 P0926EQ

Installation and maintenance:

Before installing FOXBORO FBM202 P0926EQ, several pre installation precautions are crucial. Firstly, ensure that the control cabinet has sufficient space for proper ventilation. Modules generate heat during operation, and good ventilation is crucial to prevent overheating, which can lead to performance degradation or even component failure. Proper grounding of the control cabinet is also crucial. Appropriate grounding connections can protect modules from the effects of surges and interference, ensuring their functionality. In addition, when wiring modules, follow the recommended cable types and routing paths to minimize signal interference. Ensure sufficient space is left around the module for easy operation during maintenance, including connectors, wiring terminals, and any diagnostic indicator lights.

For maintenance, it is recommended to conduct regular visual inspections. At least once every quarter, check for any signs of physical damage, such as cracked shells, loose connections, or signs of corrosion. Conduct a signal integrity test every six months to verify whether the module accurately processes and transmits signals. Maintaining module firmware updates is also crucial. FOXBORO regularly releases firmware updates to improve performance, fix vulnerabilities, and enhance security. By timely updates, you can ensure the long-term reliable operation of FOXBOROFBM202 P0926EQ. In addition, regularly check the thermocouples connected to the module to ensure they are in good working condition, as faulty thermocouples may affect the accuracy of temperature data received by FBM202.

FOXBORO Other product models:

FOXBORO E69F-T12-JRS

FOXBORO E69F-TI2-JRS

FOXBORO FBMSVH

FOXBORO XV-460-12TSB-1-10

FOXBORO FCP280 RH924YA

FOXBORO P0926GW

Foxboro FBM232

FOXBORO FCP280 RH924YA

FOXBORO RH924YA

Foxboro 43AP-PA42N/TA-3B

Foxboro 130M-N4

Foxboro 130F-N4

Foxboro 43AP-FA42C PC-00

FOXBORO RH928AW

Foxboro 127S-3EA6

Foxboro X440G2-24fx-GE4 RH102AN

Foxboro 43AP-FA42C/PB-AA

Foxboro 13A-MS2

Foxboro E69F-TI2-JRS

Foxboro 127S-2EA5

Foxboro FBM232-P0926GW

Foxboro FBM232

Foxboro IGP10-A22D1F-M2

Foxboro E69F-T12-RS

Foxboro RH924YA

Foxboro FCP280

Foxboro P0926GX

Foxboro FCP280

Foxboro FDC280

Foxboro P0926GX

FOXBORO H92 P0928DU

FOXBORO IMT33A-HA54300110002

FOXBORO H90 H90C9AA0117S

Foxboro IDP10-AF1C01F

Foxboro P0912XX

FOXBORO P0912XX

FOXBORO IDP10-AF1C01F

Foxboro E69F-T-I2-J-R-S

Foxboro IDP10-AF1C01F

Foxboro FBM232 P0926GW

Foxboro FCP270 P0917YZ

Foxboro H90JE9A001J0

Foxboro H90JE9A001J0

Foxboro E69F-B12-MRS

FOXBORO E69F-TI2-JRS

FOXBORO FBM217

FOXBORO FBM218/237 P0916QD RH101AY

FOXBORO FBM218/237 P0916QD

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626