Description

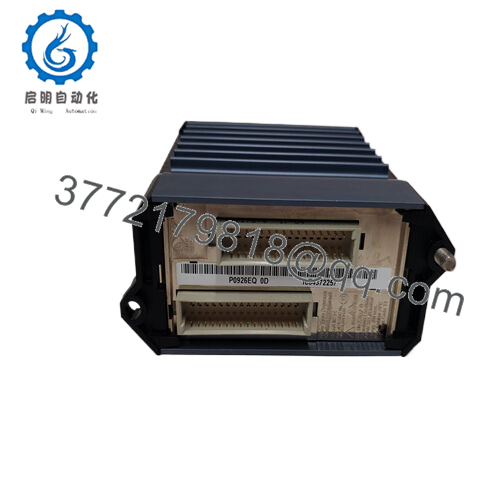

Product Model: FOXBORO FBM202 P0926EQ

Product Brand: FOXBORO (Invensys / Schneider Electric)

Product Series: I/A Series

Product Features:

- High-reliability input module for distributed control systems

- Seamless integration with FOXBORO I/A Series architecture

- Designed for harsh industrial environments with stable performance

- Easy maintenance and long lifecycle support

- FBM202 P0926EQ

- FBM202 P0926EQ

- FBM202 P0926EQ

Applications & Industry Context

Industrial facilities demand input modules that work consistently under challenging conditions, and that is where the FOXBORO FBM202 P0926EQ comes into play. In the process industries — oil and gas, petrochemicals, power generation, pulp and paper, and water treatment — accurate field data is the lifeline of operational efficiency. Each sensor reading and transmitted value directly influences control loops that keep production stable and safe.

Take, for example, a chemical plant where hundreds of temperature and pressure transmitters are scattered across multiple units. The FBM202 P0926EQ functions as the bridge between these field devices and the distributed control system. Operators rely on such modules to ensure that raw sensor inputs are translated into reliable digital values, ready for system logic and operator dashboards. Without dependable I/O performance, plants risk downtime, product inconsistency, or even safety incidents.

In power stations, where turbine conditions fluctuate rapidly, the need for fast and stable signal processing is critical. The FOXBORO FBM202 P0926EQ excels in such environments, offering resilient performance even when subjected to electrical noise and temperature variations. This capability ensures that protective systems respond on time, safeguarding both equipment and personnel.

From the perspective of a field engineer, the module’s strength lies not only in its technical design but also in its consistency across decades of FOXBORO installations. Many plants still run I/A Series systems that were installed 20 years ago, and modules like the FBM202 P0926EQ provide an upgrade path without forcing major system overhauls. This backward compatibility is one of the key reasons FOXBORO modules remain widely trusted in the automation market.

Product Role & System Fit

The FOXBORO FBM202 P0926EQ is fundamentally an input interface module, engineered to sit within the FOXBORO I/A Series distributed control system (DCS). In simple terms, it converts raw analog signals from the field into conditioned digital data that can be used by the control processors. Its design prioritizes signal integrity, meaning users get precise readings without distortion or loss.

One of the defining characteristics of this module is its compatibility with the I/A Series Fieldbus architecture. This architecture allows distributed control elements to communicate effectively, reducing wiring complexity while improving system scalability. Within this structure, the FBM202 P0926EQ assumes the role of a dependable building block, handling a defined number of inputs per unit and scaling seamlessly as plant needs expand.

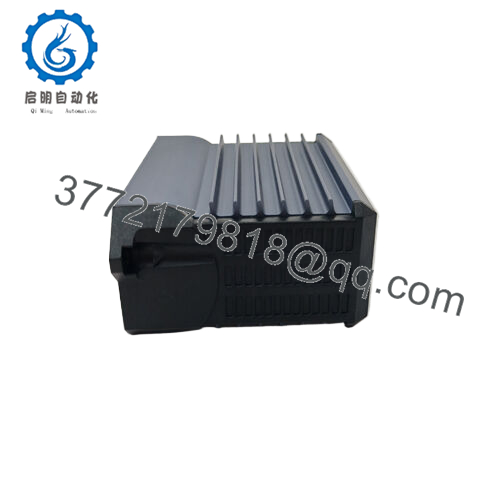

What’s particularly valuable is the way the module fits into maintenance workflows. Engineers familiar with FOXBORO systems appreciate the hot-swappable design, which allows replacement without shutting down the process. This not only minimizes downtime but also reduces the risks associated with live plant maintenance. The mechanical construction and modular housing are engineered for quick access, while the electrical connectors are designed to resist wear from repeated insertions.

From a control system perspective, the module is not an isolated piece of hardware; it is part of a larger ecosystem. The FBM202 P0926EQ aligns with a long line of FOXBORO I/A modules, ensuring consistent configuration, uniform communication protocols, and smooth integration with both legacy and newer controllers. This alignment makes it an attractive option for both plant expansions and modernization projects.

Technical Features & Benefits

When evaluating the FOXBORO FBM202 P0926EQ, it becomes clear that its design balances rugged industrial reliability with refined control performance. A closer look at its technical features illustrates why it is favored in critical applications.

The module provides multiple input channels, each electrically isolated to prevent cross-talk and interference. In environments with heavy machinery and electrical noise, this isolation directly translates into trustworthy data acquisition. Engineers can depend on the readings without worrying about drift caused by electromagnetic disturbances.

Temperature resilience is another hallmark. Process plants often experience ambient temperature shifts, particularly in field cabinets installed outdoors. The FBM202 P0926EQ withstands such conditions without signal degradation. This stability not only extends the hardware lifecycle but also improves long-term operational consistency.

In terms of diagnostics, the module supports built-in self-checking functions. Field technicians benefit from clear fault identification, which speeds up troubleshooting and minimizes unnecessary downtime. The diagnostic data can be accessed from the system interface, enabling predictive maintenance strategies — a growing priority in modern plants that aim to prevent issues rather than react to failures.

A less obvious but equally important advantage is the availability of spare parts and continued support under the Schneider Electric umbrella. FOXBORO products have a reputation for long lifecycle availability, ensuring plants can standardize on a solution without worrying about sudden obsolescence. This level of assurance is critical for industries where automation systems are expected to run for decades.

Ultimately, the FOXBORO FBM202 P0926EQ delivers a blend of performance, durability, and integration ease. For operations managers, this translates into lower total cost of ownership. For engineers, it means fewer headaches in the field. And for plant directors, it provides peace of mind that the automation backbone remains reliable.

Technical Specifications Table

| Specification | Details |

|---|---|

| Product Model | FOXBORO FBM202 P0926EQ |

| Brand | FOXBORO (Invensys / Schneider Electric) |

| Series | I/A Series |

| Module Type | Analog Input Module |

| Number of Channels | 8 (individually isolated) |

| Signal Type | 4–20 mA analog input |

| Power Supply | Redundant system power from baseplate |

| Operating Temperature Range | -20 °C to +70 °C |

| Isolation | Channel-to-channel and channel-to-ground isolation |

| Communication Protocol | FOXBORO I/A Series Fieldbus |

| Installation | DIN rail or baseplate mounting |

| Hot-Swappable | Yes |

Related Models

- FOXBORO FBM201 P0914SQ – Standard input module with different signal handling capacity

- FOXBORO FBM204 P0914SY – Output-focused version for actuator control

- FOXBORO FBM207 P0915FA – Multiplexed input module designed for high-density installations

- FOXBORO FBM217 P0916CQ – Isolated current input model for demanding environments

- FOXBORO FBM228 P0926GU – Universal I/O module supporting mixed signal types

- FOXBORO FBM233 P0926JV – High-performance input/output module with extended diagnostics

- FOXBORO FBM241 P0914WM – Specialized input unit optimized for temperature measurement

Installation & Maintenance Insights

One of the practical strengths of the FOXBORO FBM202 P0926EQ is the ease of installation. The module is designed for direct insertion into the I/A Series baseplate, with keyed connectors that minimize the risk of incorrect placement. For engineers working in live plants, this design detail saves both time and stress. Hot-swappable capability ensures that modules can be replaced while the system is running, avoiding production shutdowns.

In terms of wiring, following best practices is essential. Shielded cables are recommended for analog signals, particularly in plants with significant electromagnetic interference. Proper grounding not only protects the module but also ensures accurate signal interpretation. FOXBORO documentation provides clear guidance on terminal assignments, which field technicians should review during installation.

Maintenance is largely about preventive checks. Inspecting connectors for corrosion, ensuring environmental enclosures remain sealed, and periodically verifying calibration accuracy will extend the module’s service life. Because the FBM202 P0926EQ is backed by strong diagnostic functions, most failures are self-reported, allowing proactive action before they impact operations.

Over years of use, engineers have found that FOXBORO modules require less hands-on upkeep compared to many competitors. This reputation is not accidental but stems from robust mechanical design and carefully selected electronic components.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626