Description

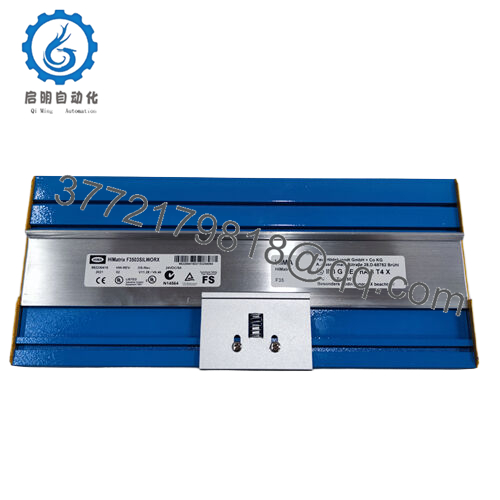

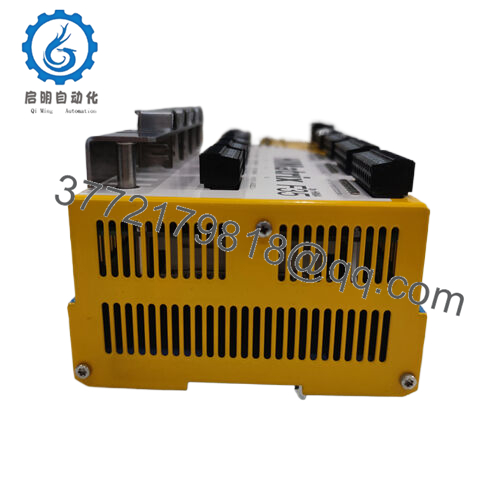

HIMA F3503SILWORX is a safety related controller located at the core of safety critical industrial systems. It is designed to seamlessly interface with various input and output devices, forming the core part of any security oriented automation infrastructure. This controller is designed to operate within the framework of industrial control systems and is typically used in conjunction with programmable logic controllers (PLCs) and distributed control systems (DCS).

F3503SILWORX

Main features and advantages:

It adopts the third mock examination redundancy (TMR) architecture, which means that there are three independent processing units continuously comparing results. If one unit fails, the other two units can still maintain system operation to ensure high availability. HIMA F3503SILWORX supports multiple communication protocols, such as PROFIBUS DP, PROFINET, and EtherNet/IP. This enables it to communicate with various on-site devices such as sensors and actuators, as well as higher-level control platforms. For example, it can receive signals (inputs) from temperature sensors in chemical reactors and send control signals (outputs) to valves to regulate the reaction process. It also has built-in diagnostic functions that can continuously monitor the health status of controllers and connected devices. This helps with early fault detection, reducing downtime and maintenance workload. This controller can be configured and programmed using SILworX software. SILworX provides an intuitive user interface for programming, configuring, and diagnosing errors in HIMA safety related controllers. This software not only helps reduce user errors, but also accelerates the engineering process, enables rapid debugging of security systems, and makes it easy to adapt to new requirements.

This product is designed for high reliability, ensuring long-term performance even in the most challenging industrial environments. Its SIL 3 certification proves its high integrity in performing safety functions. This means that in safety critical applications, such as in the oil and gas industry, HIMA F3503SILWORX can reliably prevent accidents and protect assets.

The redundant architecture of HIMA F3503SILWORX significantly reduces the risk of system failures. For example, in a continuous process manufacturing plant, any downtime can result in significant losses, while redundant processing channels ensure that the control system can operate smoothly even in the event of component failures. The built-in diagnostic function also plays a crucial role in reducing maintenance workload. By providing early warning of potential issues, engineers can plan maintenance activities in advance and minimize unexpected downtime. In addition, the compatibility of the controller with multiple communication protocols and the easy configuration achieved through SILworX have reduced engineering costs. Engineers can quickly integrate it into existing systems and customize its functionality according to specific process requirements, saving time and resources.

F3503SILWORX

Technical specifications:

Model F3503SILWORX

Brand HIMA

Type safety related controllers

Input voltage 24 VDC (-15…+20%)

Working temperature range: 0 ° C to+60 ° C

Installation method designed for standard industrial installation

Dimensions: Width: 257mm, Height: 114mm, Depth: 97mm

Weight approximately 1.2 kilograms

Interface/Bus Ethernet (4 RJ-45 interfaces, 10Base – T/100Base – TX with integrated switch), Fieldbus (3 9-pin D-sub interfaces for pluggable fieldbus submodules, FB3 with RS485 for Modbus or general user tasks)

Compliance SIL 3 certification, compliant with IEC 61508 and other relevant industry standards

Supported protocols include PROFIBUS DP, PROFINET, EtherNet/IP, Modbus

Typical power consumption: 9 A at maximum load and 0.5 A at idle

contact us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

F3503SILWORX

Application areas:

In the petrochemical industry, it is used for controlling and monitoring key processes in refineries. For example, it can manage the flow of flammable liquids, ensuring that pressure and temperature levels are always within safe ranges. In case of abnormal situations, it can quickly activate the emergency shutdown system to prevent explosions or leaks.

In the automotive manufacturing industry, HIMA F3503SILWORX is deployed to control automated production lines. It can ensure the safe operation of the robotic arm handling heavy vehicle parts. By monitoring the position and movement of these robots in real-time, it can prevent collisions, protect equipment and workers.

In the power industry, it is used in power plants to ensure the operation of turbines and generators. It can monitor parameters such as rotor speed, vibration level, and power output, and take corrective measures when necessary to prevent equipment damage and ensure stable power supply.

F3503SILWORX

Related products:

HIMA F32SILWORX – A more basic version of the F3x series, suitable for simple applications with lower safety requirements. Compared to HIMA F3503SILWORX, it may have fewer I/O points and lower processing power.

HIMA F41SILWORX – Provides higher processing power and more advanced features. For applications that require greater computing power or wider communication interfaces, it may be an upgrade option.

Siemens S7-1500F is equipped with safety software – a safety integrated PLC from Siemens. It has its own set of security features and is compatible with Siemens’ wide range of industrial products. For systems that have already invested heavily in Siemens technology, it can be considered as an alternative solution.

Rockwell Automation CompactLogix is equipped with safety features and corresponding software – integrating safety features into the CompactLogix platform. For users using Rockwell control systems and seeking safety related control solutions, this is a feasible option.

ABB AC500-S Safety Controller and Related Programming Tools – ABB’s safety oriented controller. It provides security features and communication capabilities, which may be suitable for applications that prefer ABB product ecosystems.

F3503SILWORX

Installation and maintenance:

Before installing HIMA F3503SILWORX, it is essential to ensure that the power supply meets the specified 24 VDC voltage requirements and allows for certain tolerances. Check the compatibility of communication interfaces with existing on-site equipment and control systems. Ensure that the installation location has sufficient space and meets environmental requirements such as temperature and humidity. Update the SILworX software to the latest version using official tools from HIMA to ensure optimal performance and access to the latest features and bug fixes.

During continuous maintenance, regularly check the status indicator lights on the controller. These indicator lights can indicate normal operation, faults, or communication issues. Check for signs of wear, loose connections, or damage to the connecting cables. Regularly use the built-in diagnostic function to perform diagnostic tests to detect any potential hardware or software issues. If a fault is detected, please refer to the detailed diagnostic report provided by the controller to identify and correct the problem. It is also recommended to regularly backup the configuration and program data of the controller to prevent data loss caused by hardware failures.

F3503SILWORX

HIMA Other Product Models:

HIMA PS1000WR011

HIMA F3DIO20/802 982200484

Hima F8621A

HIMA F8627X 984862765

HIMA 80105 984080105

HIMA ELOP II V5.5

HIMA 80105 984080105

HIMA X-SB01 985210207

HIMA F8628X

HIMA F8650X 984865065

HIMA A1-dig 984200004

HIMA X-AI3201 985210213

HIMA TRIX F35 982200416

HIMA F3DIO20/802 982200442

HIMA F8650E

HIMA F3226A

HIMA F8621A 984862160

HIMA F-PWR01

HIMA F3DIO16/801

HIMA Z7130

HIMA F3240

HIMA F30 03 SILworX 20/9

HIMA F3237

HIMA F8651X

HIMA F3DIO20/802 982200404

HiMA F35 030 34 SILworX

HIMA F-COM01

HIMA F-IOP01

HIMA F30 F30 010 20 OS-REV.V6.46/V11.28

HIMA F30 F30 010 20 OS-REV.V6.46/V11.28

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626