Description

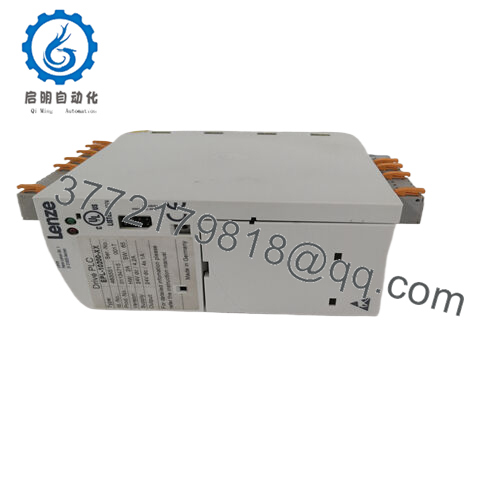

The EPL10200-W is a powerful servo drive and motor controller system primarily used in industrial automation to manage high-precision motion control applications such as packaging lines, robotics, material handling, and manufacturing machines. It is designed to interface with servo motors to provide accurate position, speed, and torque control, making it a cornerstone device for achieving process efficiency and repeatability in automated setups.

- EPL10200-W

As part of the Lenze family of servo drives, the EPL10200-W offers robust features including high current output and multiple integrated control functions that enable it to handle complex motion tasks efficiently. It supports industrial protocols for communication and integrates seamlessly with plant-wide control systems and PLCs. Its design supports compact mounting and includes reliability measures such as thermal and overcurrent protection to ensure consistent operation in harsh environments.

Technically, this unit provides power ratings typically around 2 kW with voltage inputs at 24 VDC common for servo drive amplifiers in its class. Its advanced control algorithms optimize motor performance and energy consumption, while built-in diagnostics offer real-time system monitoring and fault detection to reduce downtime. The device is suited to environments requiring precise synchronization of multiple axes and rapid dynamic response.

| Parameter | Value |

|---|---|

| Model | EPL10200-W |

| Brand | Lenze |

| Type | Servo Drive and Motor Controller |

| Power Rating | Approximately 2 kW |

| Voltage Input | 24 VDC |

| Communication | Industrial Ethernet, fieldbus protocols possible |

| Protection | Overcurrent, thermal monitoring |

| Mounting | Panel or DIN rail compatible |

| Operating Temp | Industrial standard range (~0°C to 45°C) |

| Diagnostics | Real-time monitoring, fault alerts |

Related Lenze products include the EPL10203 extension modules for increased I/O capabilities and other Lenze servo motors designed to work cohesively with the EPL drive series. The system supports modular expansion tailored to diverse automation needs.

Installation considerations emphasize proper ventilation, secure mounting, and adequate power supply capacity. Thorough electrical grounding and shielding are necessary to maintain signal quality and reduce electromagnetic interference. Preventive maintenance includes periodic firmware updates, inspection of cooling components, and verification of electrical connections.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626