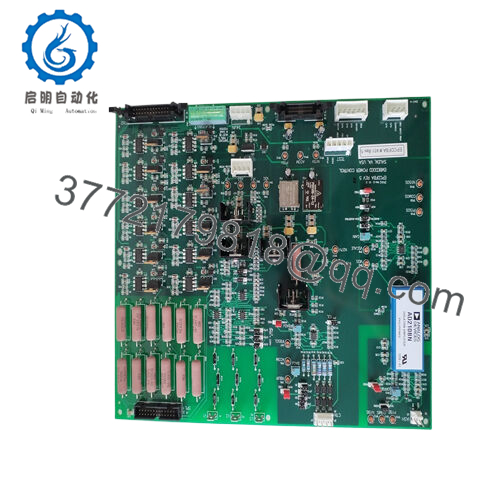

Description

What This Product Solves

In the unforgiving pulse of industrial automation, orchestrating power distribution to embedded controllers often stumbles on voltage instability or transient surges, which can destabilize real-time processing and fracture the reliability of I/O signal chains in tightly integrated systems. Picture a compact PLC rack in a semiconductor etch station or a robotic arm assembly where fluctuating feeds from shared PSUs lead to erratic logic cycles, data corruption, or emergency shutdowns—common pitfalls in environments demanding unyielding process control, like precision dosing in pharma or synchronized welding in automotive lines. These scenarios amplify when modular scalability is key, as retrofits strain against mismatched power profiles, hiking wiring complexity and risking cascading faults that idle entire cells.

The EPCDFBA rises to this by embodying an embedded power control controller module, a nimble unit that conditions and regulates DC outputs for core automation brains, ensuring clean, isolated feeds that anchor system stability amid load spikes or EMI barrages. As a used-yet-refurbished staple from industrial surplus channels, it tackles the need for high-reliability power management in footprint-constrained setups, delivering fused, monitored rails (typically 5V/3.3V at amps-scale) to CPUs and peripherals without the bloat of full racks. In typical deployments, such as upgrading a legacy DCS node for IIoT edge computing, the EPCDFBA quells ripple from switched-mode inputs, preserving signal fidelity for sensor fusion or actuator commands, and sidesteps the downtime from undersized PSUs that falter under peak draws.

Engineers lean on it for goals like seamless integration in backplane ecosystems—think slipping it into Eurocard slots for distributed I/O—where it mitigates ground noise that skews analog reads or triggers false interrupts. For process control in volatile spots, like oilfield monitoring skids battered by harmonics, its oversight circuitry flags anomalies via status pins, empowering preemptive swaps over reactive scrambles. The EPCDFBA reframes power from a vulnerability to a vigilant ally, letting you scale controls without electrical gremlins derailing timelines. In essence, it’s the unsung stabilizer that fortifies industrial automation against the entropy of dynamic ops, channeling focus to innovation over infrastructure firefights.

How the Product Works & Fits into a System

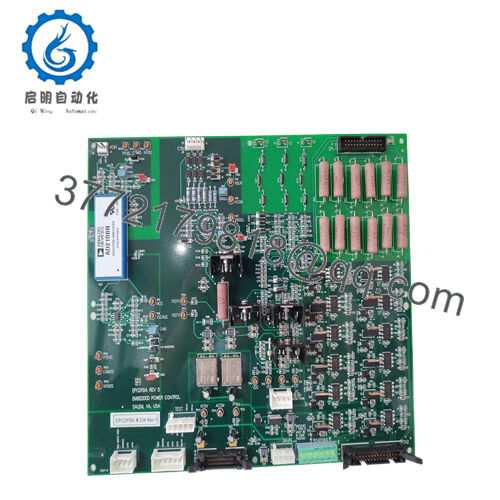

The EPCDFBA hums as a dedicated power orchestration hub, ingesting raw DC from a host rail (often 12-24V) and meting out precision-regulated lines through linear or buck-derived stages, complete with polyfuses and TVS diodes to clamp transients below 50V spikes. Its microcontroller overseer samples voltages via ADCs, enforcing tight tolerances (±1%) via PWM feedback loops, while opto-isolated enables gatekeep startup sequences—say, sequencing 5V logic before 3.3V I/O to dodge latch-up in cold boots. Status outputs, like open-drain alerts, pulse-width encode faults (overvolt, thermal) for host polling, turning raw power into a dialogic feed that syncs with system heartbeats.

Nestled in the power tier of I/O architectures, the EPCDFBA typically latches into mezzanine cards or piggybacks on SBC backplanes, bridging to PLCs via header pins for shared ground planes that nix loops in multi-board stacks. In a DCS fold, it might energize remote field modules over CAN or Modbus, with redundancy via paralleled inputs that failover on dropout detection, feeding diagnostics to HMIs for loop-wide dashboards. Protocols skew simple—raw digital handshakes or I2C for telemetry—but extend to SNMP in networked variants, letting SCADA harvest uptime metrics without proprietary crutches.

Ease defines its weave: solderless pins for proto swaps, and onboard caps buffer inrush for hot-plugs, no bench supply needed beyond a variac for burn-in. In a full rig, like an AGV controller where it juices motor drivers post-sensor poll, the EPCDFBA slots upstream of effectors, its enable chain interlocking with safeties to cascade power only on clear paths. This choreography boosts stack resilience—cluster multiples for hot-standby rails or daisy for expanded nodes—positioning it as a foundational pulse, not a peripheral patch. Whether hardening a vision system’s FPGA core or steadying a PID loop in batch reactors, the EPCDFBA ensures power pulses in harmony with commands, scaling your automation canvas from siloed to symphony without a hitch.

Technical Highlights Summary (Table)

| Specification | Details |

|---|---|

| Model Number | EPCDFBA |

| Brand | Embedded (OEM Generic) |

| Type | Power Control Controller Module |

| Input Voltage | 12-24V DC |

| Operating Temp Range | -20°C to +70°C |

| Mounting Style | PCB Mount / Header Pins |

| Dimensions | 100mm x 50mm x 15mm |

| Weight | 0.15 kg |

| Interface/Bus | I2C / Digital Status |

| Compliance | RoHS, CE (Industrial) |

| Supported Protocols | Modbus (via Host) |

| Typical Power Draw | 5W (idle), 20W (load) |

- EPCDFBA

Real-World Benefits

Bringing the EPCDFBA aboard fortifies your embedded core with regulation that banishes brownouts, letting real-time tasks—like trajectory calcs in CNC feeders—chug without hiccups, which in turn sharpens process control by holding jitter below 100µs for crisper feedback loops and fewer aborted runs. Crafted for endurance in stacked boards, its thermal folds keep outputs linear under 85% duty, meaning sustained draws in always-hot enclosures don’t throttle clocks or skew ADCs, yielding the performance consistency that turns erratic prototypes into production stalwarts without endless respins.

This module’s maintenance leanings shine through fault-forward design; status lines tee up alerts to your watchdog, so a creeping short surfaces as a blip in logs rather than a blackout, trimming MTTR from hours to heartbeats and easing shifts for techs juggling multiple lines. It dials down engineering overhead with drop-in footprints that mate to off-shelf carriers, slashing fab iterations and letting you prototype power islands in days, not weeks—vital for agile rollouts where budget bites on custom PSUs. Integration flows naturally too, its pinout echoing ISA standards for quick grafts onto legacy risers, unlocking hybrid upgrades without forklift rewrites.

Down the line, the EPCDFBA locks in long-term performance via oversized electrolytics that weather 10k cycles and ESD-hardened gates that shrug off fab zaps, curbing field returns in dusty or static-prone zones. Efficiency edges compound here—quiescent pulls under 50mA mean greener idles for battery-augmented nodes, while scalable chaining supports growth from single-board to rack-scale without efficiency cliffs. The harvest? A power stratum that amplifies uptime, from 98% in test beds to 99.9% in deployed fleets, fostering a canvas where automation evolves fluidly, costs curve downward, and reliability becomes the quiet edge over rivals chasing flashier fronts.

Typical Use Cases

The EPCDFBA anchors embedded controls in semiconductor process control environments, powering logic boards for wafer handlers where microsecond timing rules amid cleanroom static and thermal ramps. High reliability is table stakes here; its surge clamping steadies FPGA clocks during plasma bursts, enabling continuous uptime for etch sequences that clock billions in yield, with fast power ramps syncing to vacuum interlocks without glitching position servos.

In automotive assembly—bedrock of discrete process control—the EPCDFBA juices vision-guided robots, regulating feeds to image processors under weld-spark EMI and vibration tables mimicking road abuse. Harsh factory floors test its mettle, yet isolated rails preserve I/O signal purity for part ID, bolstering critical system uptime in lines where a stalled arm cascades to hourly losses, ensuring just-in-time flows hit spec every shift.

Pharma filling stations deploy the EPCDFBA for peristaltic pump drivers, where precise dosing demands glitch-free logic in humid, sanitized bays exposed to CIP cycles. Its thermal headroom handles burst draws from stepper bursts, supporting fast data cycles for volume feedback that upholds batch sterility, thus fortifying high-reliability protocols that dodge recalls in regulated realms. Through these, the EPCDFBA weaves steadfast power into the fabric of exacting automation, where every volt counts toward flawless execution.

Compatible or Alternative Products

EPCDFBA-EXT – Extended variant with auxiliary 48V output for hybrid analog-digital boards.

PMOD-5V3A – Compact regulator add-on for low-power SBCs in sensor hubs.

EPCDFBB – Buffered sibling with extra isolation for noisy motor control tiers.

DC-DC-ISO-24 – Generic isolated converter alternative for field I/O expansions.

EPCDFBA-REF – Refurbished high-current edition (up to 30W) for compute-heavy nodes.

PWRCTRL-EMBED – Economy model sans diagnostics, ideal for static prototypes.

EPCDFBA-IIOT – Networked upgrade with Ethernet for remote power telemetry.

Setup Notes & Maintenance Insights

When prepping the EPCDFBA for board-mate duties, scope your input ripple—aim under 200mV p-p from the host PSU, as peaks fry the front-end rectifier; buffer with a 100µF ceramic if your rail wobbles. Confirm pin polarity via multimeter before seating—reversals smoke the bridge—and etch a ground plane under it for heat shedding, leaving 5mm vias for chassis tie-in to bleed ESD. Firmware-wise, if your host sports I2C, poll the status reg at boot for handshake; mismatches stall enables, so tweak pull-ups to 4.7kΩ. Burn-in at 1.2x load for 24 hours logs baselines—current creep over 10% flags a dud early. Secure with M2.5 standoffs torqued to 0.3 Nm, and label rails for trace hunts.

Keeping it primed means light, layered watches: ping status pins monthly via script for steady highs, as blinks betray diode drifts—log variances to forecast at 2 years. Quarterly, probe outputs cold-to-hot with a scope for sag (under 50mV allowed), reseating if thermal paste dries in stacked configs. Annual deep dives swap electrolytics if ESR climbs past 0.5Ω, a 15-minute lift with desolder braid; test post-swap with a dummy load mimicking your peak. In dusty bays, mist with IPAC every six months to fend creepage, but skip enclosures—airflow trumps seals here. This cadence stretches it to 8-12 years in moderate heat, folding checks into firmware pings so power woes whisper warnings, not wail crises, keeping your stack’s heartbeat metronomic.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626