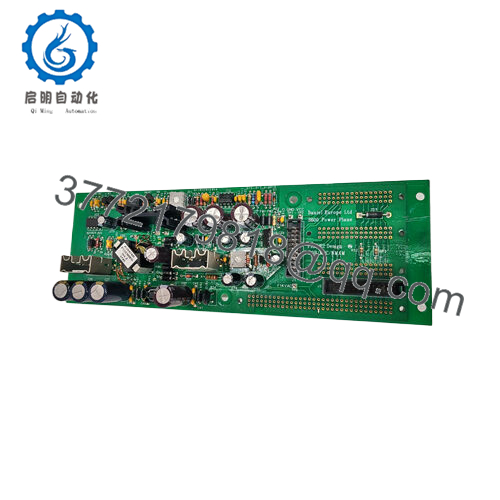

Description

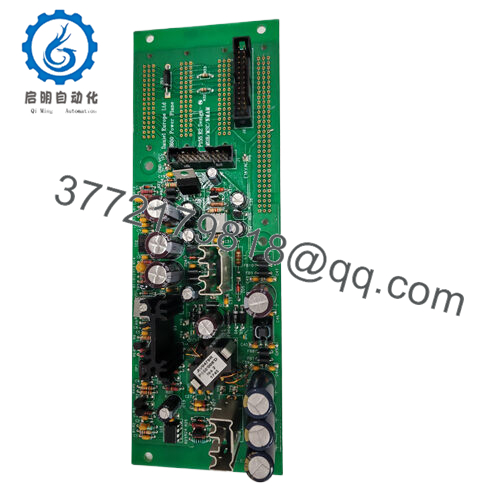

The Emerson P155.R2 is commonly used in industrial automation systems where reliable signal connection and distribution play a crucial role. This module is typically found in manufacturing plants, process control environments, and power generation facilities where precise and stable interconnection between control signals and input/output modules is necessary. The P155.R2 ensures consistent and secure communication pathways, overcoming challenges such as electrical noise and potential signal degradation in complex automation networks.

Industries depend on the P155.R2 for its galvanic isolation capabilities and robust interface design, making it suitable for environments subject to electrical interference, as it enhances signal integrity and system reliability. It is especially valuable in applications requiring long cable runs and high-density I/O systems.

Product Introduction and Positioning

The Emerson P155.R2 is an industrial control communication and interface module designed to provide critical connectivity and signal distribution for VersaMax I/O systems and other Emerson automation equipment. Its primary function is to enable galvanically isolated connections between input/output modules and the control system, supporting both analog and digital signals.

Designed to operate within harsh industrial conditions, the P155.R2 supports stable and noise-resistant communication channels. It is positioned as a vital component for system integrators and automation engineers seeking reliable hardware to ensure seamless data transmission and signal integrity in distributed control architectures.

Key Technical Features and Functional Benefits

The P155.R2 features galvanic isolation between channels, rated at 1500 Vrms, effectively preventing ground loops and interference from contaminating system signals. It supports operating temperatures from -20 to +70 °C, designed to withstand industrial environmental stresses including vibration and electrical noise.

This module offers multiple input and output channels that connect control and field modules via isolated pathways, allowing multiple devices to communicate accurately without cross-interference. The robust physical design with secure connectors ensures long-term durability and ease of maintenance in factory settings.

Integrated with standard industrial communication protocols including Modbus RTU, HART, and Ethernet/IP, the P155.R2 facilitates quick and reliable data exchange suitable for modern process control systems.

- P155.R2

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | P155.R2 |

| Brand | Emerson |

| Product Type | Industrial Control Interface Module |

| Function | Signal connection and distribution |

| Isolation | 1500 Vrms galvanic isolation |

| Operating Temperature Range | -20 to +70 °C |

| Communication Protocols | Modbus RTU, HART, Ethernet/IP |

| Input Channels | 16 digital inputs |

| Output Channels | 16 relay outputs |

| Power Supply | 24 V DC |

| Dimensions | Compact industrial form factor |

| Application | VersaMax I/O and Emerson automation systems |

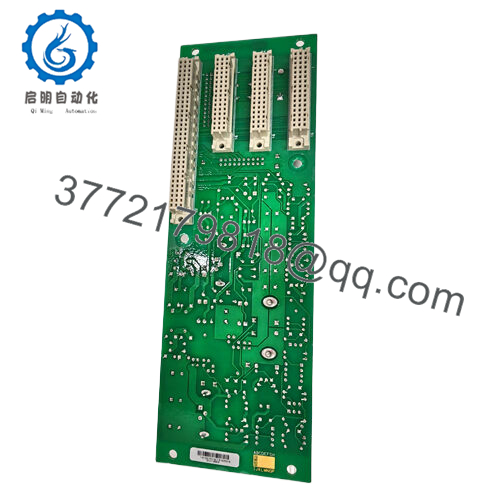

Related Modules or Compatible Units

P188.R2 – Power interface board providing stable and precise power supply.

P155.R3 – Similar interface module with expanded channel capacities.

VersaMax I/O Modules – Various discrete and analog I/O modules designed for versatile automation solutions.

DeltaV Controllers – System controllers that integrate with P155.R2 for process automation.

Installation Notes and Maintenance Best Practices

Install the P155.R2 module securely in well-ventilated control panels with adequate grounding and shielding practices to minimize interference. Careful wiring and connector installation improve communication quality and reduce maintenance frequency.

Maintenance includes regular inspection of connector integrity, firmware updates, and monitoring operational diagnostics if available. Ensuring clean electrical environment and minimizing exposure to excessive vibration extends module life and system reliability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626