Description

Emerson P152.R4 is a critical component in the automation stack. It can effectively interface with various control platforms and backplane systems, highly adapting to existing settings. This module supports multiple industry standard protocols, such as Modbus TCP and Profibus, and can seamlessly integrate with a wide range of field devices.

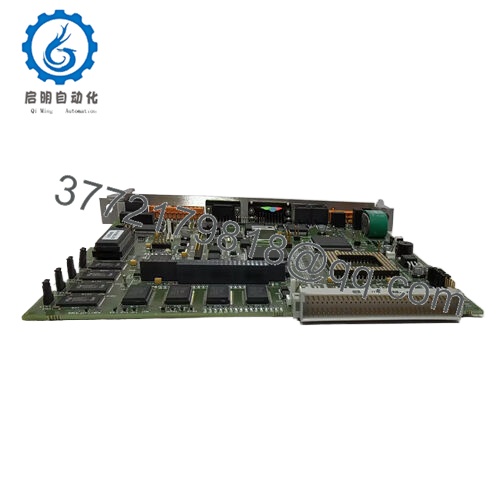

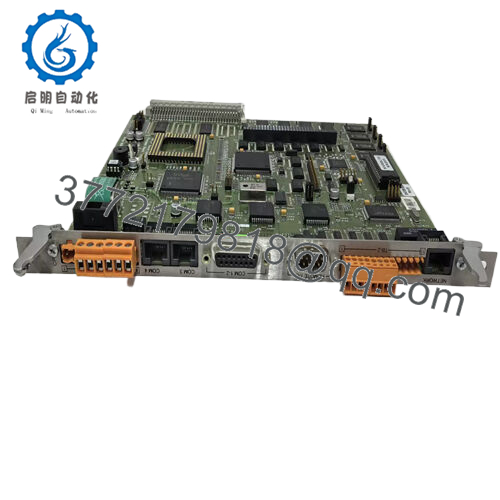

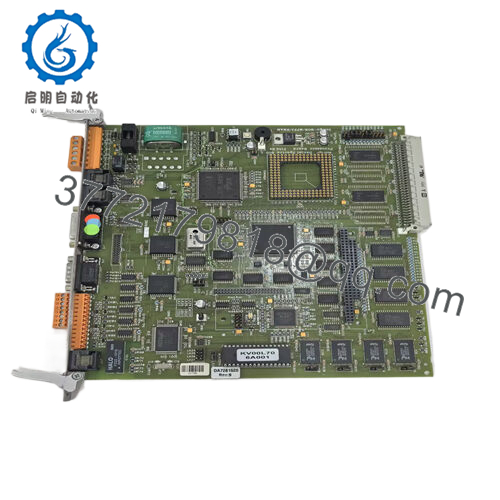

P152.R4

Emerson P152.R4 has built-in redundancy function to prevent unexpected failures. When a component fails, the redundant system takes over the work, minimizing downtime and ensuring continuous operation. Its diagnostic function is advanced and can monitor the health status of the module in real time. This enables operators to detect potential problems early and take preventive measures to prevent major system failures from occurring.

P152.R4

Technical specifications:

Model P152.R4

Brand Emerson

Type: Pressure transmitter module

Installation method: DIN rail installation

Interface/Bus Ethernet RS – 485

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

P152.R4

Main features and advantages:

Its high reliability design can withstand harsh industrial conditions, including extreme temperatures, high humidity, and vibration. This means fewer component replacements and less downtime, resulting in significant cost savings. The user-friendly integration function of this module reduces engineering costs. Its simple setup process enables your team to quickly deploy modules, allowing them to focus on optimizing operations rather than dealing with complex installation issues. The built-in diagnostic function transforms maintenance from passive response to proactive prevention. Operators can schedule maintenance activities during planned downtime to extend the lifespan of modules and ensure sustained and stable performance. This is particularly important for industries that strictly control product quality and production goals.

P152.R4

Application areas:

In the oil and gas industry, it can be used to monitor and control pipeline pressure, ensuring safe and efficient transportation of fluids.

In the food and beverage industry, this module enables precise control over processes such as filling and packaging, maintaining product quality and consistency.

Accurate monitoring of process variables is crucial for safety and productivity in chemical plants, and Emerson P152.R4provides reliable data acquisition and control capabilities. Its ability to handle fast data cycles and operate reliably under various conditions makes it an indispensable part of any industrial automation system.

Related products:

Emerson P153.R5- With enhanced processing capabilities and additional features, it is suitable for more complex applications.

Emerson P140. R3- has basic functions and is suitable for low demand automation tasks.

Emerson P152- HAZ.R4- Designed for use in hazardous environments, such as areas with explosive gases or flammable substances.

Emerson P152- EXT.R4- with an extended temperature range, suitable for outdoor applications or extreme cold conditions.

Emerson P152- PRO.R4- Provides advanced features such as advanced diagnostic capabilities and faster data transfer rates.

Emerson P152- RF.R4- Integrated wireless communication function, suitable for applications where wired connections are impractical.

Installation and maintenance:

Before installing Emerson P152.R4 it is essential to verify its bus compatibility with the existing control system. This ensures a smooth integration process without any compatibility issues. Check if the firmware version is consistent with Emerson’s latest version to access the most stable features and security enhancements. There must be sufficient heat dissipation space around the module, especially in high-density installations, to prevent overheating and ensure optimal performance.

For continuous maintenance, the LED status indicator lights of the module should be checked regularly. These indicator lights can provide valuable information about the health status of the module, allowing you to quickly identify any abnormalities. Check for signs of wear or corrosion on the connector, as these can affect signal quality. Conducting functional testing once a year, including data transmission checks and protocol validation, helps maintain optimal module performance and identify potential issues in the early stages.

Other product models of EMERSON:

EMERSON 5X00500G01

EMERSON 1C31129G03

EMERSON 1C31224G01

EMERSON 1C31234G01

EMERSON 5X00453G01

EMERSON 5X00846G01

EMERSON 5X00790G01

Emerson KJ3242X1-BK1 12P4711X042

Emerson MGE-4120-CONS-0000

EMERSON A6110

Emerson FB107

Emerson OCR3000

EMERSON KJ4001X1-BE1

EMERSON NTE207-CBNS-0000

Emerson MMS6410

Emerson PR9268/202-000

Emerson 1C31189G03

Emerson XC-CPU201-EC512K-8DI-6DO

Emerson 5X00784G01

EMERSON VE3006

EMERSON VS3202

EMERSON NTE-207-CBNS-0000

EMERSON PRPMC8150-4371

Emerson VE3008 CE3008 KJ2005X1-MQ1

Emerson VE3007 KJ2005X1-BA1

Emerson PR6423/00R-000+CON021

Emerson CWM-30-08 396879-11-0S

EMERSON 1C31132G01

Emerson DA7281440

Emerson SE3008

EMERSON 4001S2T2B4 (KJ3203X1-BA1+KJ4001X1-CJ1 )

EMERSON 396563-06-6

Emerson SS4605T02

Emerson FLOBOSS S600

Emerson FLOBOSS S600+

Emerson MVME55006E-0163R

EMERSON DA7281440

Emerson DXP-L21ZNEB

Emerson A6210

Emerson ST320A-100-ASSY

Emerson A6125

EMERSON HART475

Emerson 396571-02-6

Emerson 5X00419G02

Emerson NTE-212-CONS-0000

Emerson MGM455-CONS-0000

Emerson MGE-208-CONS-0001

Emerson SS3001 KL2001X1-BB1 KL4001X1-BA1

EMERSON KJ2005X1-SQ1

EMERSON PR6424/011-140

EMERSON CON021

Emerson 701PBKKF

Emerson KL4103X1-BA1

Emerson KL2001X1-BA1

Emerson 5X00481G03

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626