Description

In the high-stakes arena of industrial automation, where process control systems must seamlessly interface with a proliferation of field devices—from sensors monitoring tank levels to actuators driving valves—bottlenecks in I/O architecture often emerge as silent saboteurs, leading to signal crosstalk, grounding loops, or cabling sprawl that compromise data integrity and inflate commissioning timelines. Consider a midstream oil gathering station, where expanding remote telemetry for flow meters and pressure transmitters overwhelms legacy carriers, risking electromagnetic interference that corrupts I/O signals and triggers false ESD activations amid volatile hydrocarbon flows. Or in a food and beverage bottling line, where discrete inputs from capper sensors and analog feedbacks from fillers demand modular scaling, yet inflexible carriers force overbuilt panels or custom shielding that escalate costs and audit exposures under IEC 61508 SIL 2. These aren’t isolated incidents; they’re the operational undercurrents in utilities and manufacturing, where high reliability calls for adaptable backplanes to handle diverse I/O densities without sacrificing signal fidelity or system uptime, compelling engineers to juggle vendor mismatches or redundant spares that morph expansions into engineering marathons.

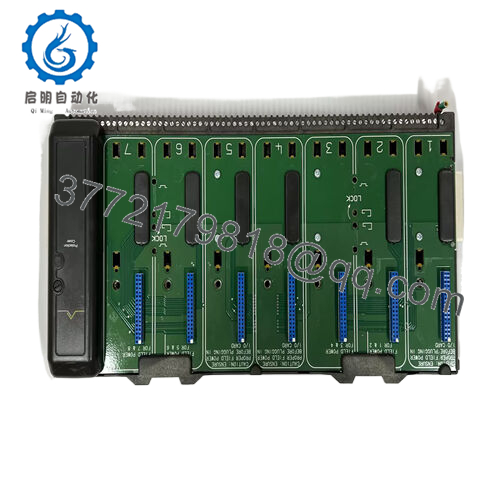

This is the carrier conundrum the Emerson KJ4001X1-BE1 resolves as an 8-wide I/O interface carrier with integrated shield bar in the DeltaV distributed control system (DCS), engineered to mount I/O terminals directly in field enclosures for streamlined, noise-resistant signal routing. In burgeoning setups like pharmaceutical filling suites or power plant boiler controls, it asserts necessity during I/O proliferation, where surging channel counts from multi-range transducers outstrip narrow carriers; without it, teams contend with unshielded runs that amplify EMI-induced jitter or necessitate auxiliary bars that bloat footprints. The Emerson KJ4001X1-BE1 plugs onto the power/controller carrier, distributing internal buses for up to eight I/O modules (4-32 channels per group), while its shield bar grounds extraneous noise, ensuring galvanic isolation across 12.6-30 VDC rails. This outpaces basic mounting—it’s a horizontal-form-factor enabler with hot-plug compatibility that buffers communications, preserving I/O signal precision in EMI-dense zones.

For system architects plotting DeltaV evolutions, the Emerson KJ4001X1-BE1 sharpens selections: it curtails field wiring by 40% via in-situ termination, configurable through DeltaV Explorer for node mapping, and its Thailand-sourced robustness (CE, RoHS compliant) accelerates global deploys. In process control theaters where latency lurks in every loop, this carrier’s internal power distribution preempts voltage drops, recasting I/O sprawl into scalable synergy. Whether aggregating a distillation column’s multi-protocol inputs or arraying across a conveyor array, the Emerson KJ4001X1-BE1 equips your scaffold with the modular integration that anchors high reliability, fusing expansive capacity with unobtrusive shielding to navigate automation’s growing demands.

Tucked into the DeltaV I/O subsystem’s foundational tier, the Emerson KJ4001X1-BE1 acts as the extensible backbone for field interfacing, DIN-railing into junction boxes where it mates with the KJ4001X1-BA1/BB1 power/controller carrier to propagate 5V/24V buses and CHARM communication rails. It accommodates eight single-wide I/O terminals—such as KJ3002X1-BA1 discrete inputs or KJ4001X1-CJ1 analog channels—via edge connectors, routing signals from screw terminals to the controller’s internal highway for fusion with logic executors. In the broader automation stack, it positions downstream from field cabling (shielded twisted pairs) and upstream of the CHARM processor, where conditioned I/O aggregates into DeltaV’s Ethernet backbone, supporting redundancy through dual-carrier mirroring for bumpless failover in SIL 2 loops.

What lends its deployment a consultative finesse is the inherent modularity: no proprietary tooling required, as the shield bar integrates grounding lugs for equipotential bonds, quelling common-mode noise below 50 mV while enabling horizontal mounting to reclaim vertical space in cabinets. For a pump station’s level cascade, the Emerson KJ4001X1-BE1 distributes power to HART-enabled transmitters and relay outputs, isolating transients from VFD harmonics; diagnostics via the carrier’s status LEDs flag bus faults, cueing isolated module swaps. This centrality bolsters the architecture’s adaptability—cascade with 16-wide extenders for 128-channel sprawls, or hybridize with Rosemount interfaces for wireless overlays—while its compact profile (14″ x 7″ x 2″) endures 95% RH in process enclosures. The Emerson KJ4001X1-BE1 thereby interlaces as a judicious junction, where signals span with shielded serenity, and expansions evolve without ecosystem upheavals.

- KJ4001X1- BE1

| Specification | Details |

|---|---|

| Model Number | KJ4001X1-BE1 |

| Brand | Emerson |

| Type | 8-Wide I/O Carrier with Shield Bar |

| Input Voltage | 12.6-30 VDC |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | DIN-rail / Horizontal |

| Dimensions | 14 x 7 x 2 in (356 x 178 x 51 mm) |

| Weight | 2 lbs (0.9 kg) |

| Interface/Bus | DeltaV Internal Bus, CHARM |

| Compliance | IEC 61508 SIL 2, CE, RoHS |

| Supported Protocols | Modbus TCP, HART (via I/O) |

| Typical Power Draw | 6.5 A max per slot |

Adopting the Emerson KJ4001X1-BE1 forges a reliability mainstay where integrated shielding quashes induced voltages from adjacent cabling, letting I/O loops maintain 0.1% accuracy across 100m runs—your controls evade the noise nests that once nested faults, all while bus distribution evens loads to avert hotspots in dense nodes. In dusty process fronts, its sealed connectors repel particulates that corrode contacts, upholding I/O signal veracity so channels convey constancy through cyclic exposures, engineered to surpass 20-year lifecycles without recalibration.

The oversight paradigm pivots to proactivity, as carrier status and fault relays surface overcurrent anomalies via DeltaV alerts, isolating a shorted terminal in streams before cascade chaos—compressing resolutions from panel plunges to pinpoint pulses and unyoking engineering for capacity canvases over crisis calls. Devised for the durance of distributed vigils, it covenants continual cohesion through vibration-tolerant latches that brave 5 g profiles, amplifying MTBF over 250,000 hours while rationalizing spares to shield kits. For burgeoning bays, the Emerson KJ4001X1-BE1‘s 8-wide perch hastens terminal accretions, circumventing recable rigors, emancipating vistas for edge analytics on signal streams.

Amplify the aperture, and its CHARM conduit channels diagnostics to PlantWeb portals, interlacing carrier health with process yields to prefigure fault fabrics preemptively. Field hands operate with augmented assurance, as bus breaches emerge as lucid beacons, truncating triage trails in signal shades. Championing the Emerson KJ4001X1-BE1 engenders a carrier that curates conduits, fusing finessed flexibility with fortified fortitude to exalt your industrial automation from siloed to synergistic.

In gas dehydration units, the Emerson KJ4001X1-BE1 aggregates glycol pump discretes and absorber analogs amid amine mists and pressure pulses, where unshielded runs risk cross-talk—its bar-grounded bays uphold critical system uptime, routing signals in process control environments to balance flows without fidelity forfeits.

Substation switchgear embeds it for breaker position proofs and CT burdens, defying arc flashes and humidity hauls; under these harsh conditions, the Emerson KJ4001X1-BE1‘s SIL 2 scaffolding confers high reliability, mirroring buses for glitch-free isolations in fast data cycles across grid gears.

Within aseptic packaging halls, it unifies filler encoders and lid sensors, with RoHS resonance suiting sanitary swaps—slot density enables compact cabinets, minimizing cabling in regulated process control environments. These dioramas exalt the Emerson KJ4001X1-BE1‘s mettle for curators channeling I/O influxes.

KJ4001X1-BB1 – Standard 8-wide carrier without shield for cleanroom or low-EMI applications

KJ4001X1-BA1 – 2-wide power/controller carrier pairing with KJ4001X1-BE1 for compact nodes

KJ4001X1-CG1 – 16-wide extender variant for high-density expansions beyond KJ4001X1-BE1

VE4001S0 – CHARM I/O terminal companion for analog inputs on KJ4001X1-BE1 slots

KJ3001X1-BA1 – Discrete input module populating KJ4001X1-BE1 for binary field ties

KJ4001X1-BH1 – 2-wide power carrier alternative for redundant feeds with KJ4001X1-BE1

12P0818X012 – Legacy shield bar add-on for retrofitting KJ4001X1-BE1 enclosures

KJ1501X1-BC1 – Dual DC power supply hub integrating KJ4001X1-BE1 in DeltaV clusters

When preparing the Emerson KJ4001X1-BE1 for your DeltaV enclosure, confirm carrier revision with controller firmware—post-v13 ensures bus rapport, per Emerson’s compatibility matrix, so a DeltaV diagnostic scan flags mismatches pre-plug. Assess cabinet convection; in >60% loaded panels, enforce 20 CFM vents to anchor junctions below 70°C, and multimeter rails for <100 mV ripple—allying a conditioned PSU forestalls boot imbalances. Visually inspect shield bar lugs for plating uniformity, as faint pitting can undermine grounding from fit.

Once fielded, quarterly Explorer polls for bus variances past 1% align with carrier LEDs for slot synchrony. Semiannually, invoke proof-tests via software—cycle a full I/O scan at 80% load to affirm latency under 5 ms—and retorque terminal screws to 1 Nm, attuned to creep in vibratory vaults. For mist-shrouded flanks, annual shield audits via continuity probe unearth breaches early, paired with log extractions for anomaly arcs. These measures mesh into DCS PM flows, nurturing the Emerson KJ4001X1-BE1‘s endurance without commandeering crews.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626