Description

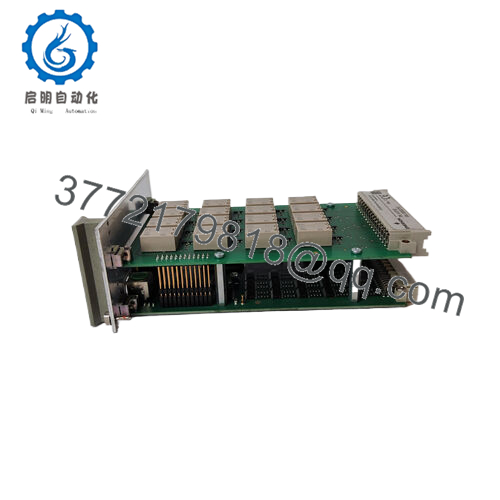

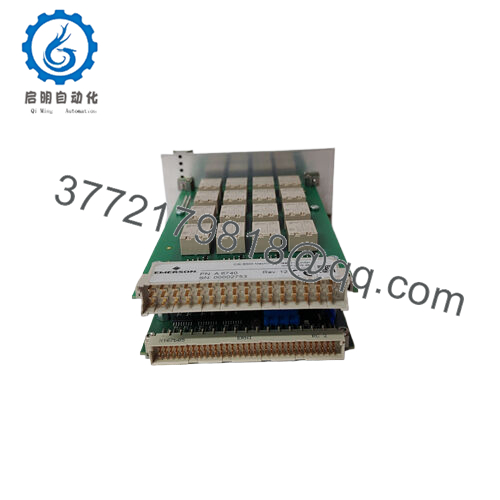

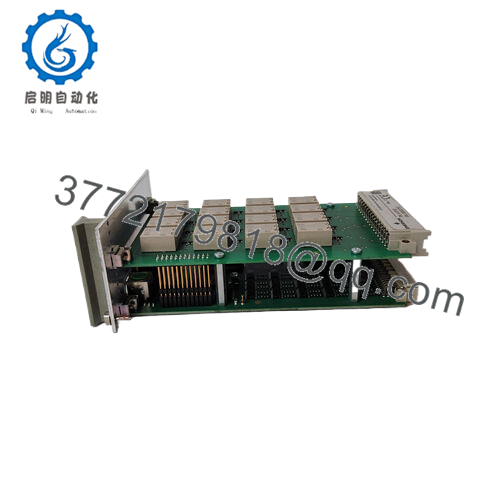

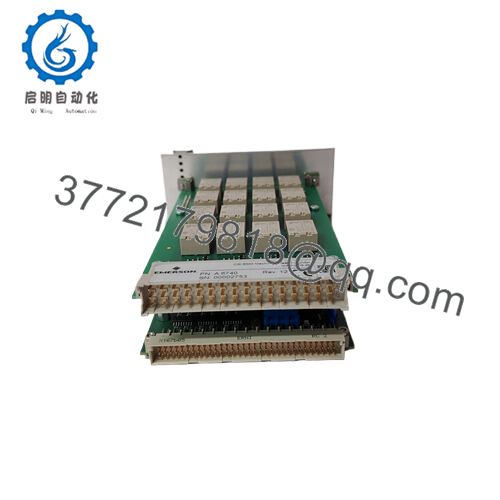

The Emerson A6740 is a 16-Channel Output Relay Module engineered for high reliability in the monitoring and protection of critical rotating machinery within industrial plants. It is commonly deployed in industries such as power generation, petrochemical, steam, gas, compressor, and hydro-turbomachinery sectors where machinery health and safety are paramount. The module is a vital part of the AMS 6500 Machinery Health Monitor system, which integrates condition monitoring capabilities with Emerson’s PlantWeb and AMS Suite software platforms. This integration provides maintenance teams with advanced predictive diagnostics and performance analysis tools to detect machinery malfunctions early, ultimately enhancing operational availability and preventing unplanned downtime.

The module is a compact 3U sized, 2-slot plug-in device that effectively reduces the required cabinet space by half compared to traditional 6U cards. It is API 670 compliant and features 16 mechanical relay outputs that are redundant and configurable for high-reliability control functions. These relays can be programmed with Boolean logic, time delay, and selectable outputs, supporting complex alarm and control schemes. The module processes up to 60 inputs from the monitoring system and allows for defining up to 30 logical expressions, enabling sophisticated signal processing and relay control. Installation and configuration are supported by user-friendly graphical software, simplifying the setup of relay logic and system responses.

- A6740

- A6740

The Emerson A6740 stands out with its versatility and robust design. It accepts control voltages from 13 to 32 V DC and supports contact loads up to 48 V and 1 Ampere per relay channel. Relays are single-pole double-throw (SPDT) and can be configured as normally open or normally closed, and energized or non-energized. The module supports configurable redundancy in relay outputs to enhance system dependability. It operates reliably in industrial environmental conditions with temperature ratings from 0 to 65 °C and storage from -40 to 70 °C. The module is vibration and shock resistant, compliant with EMC standards, and designed for protection up to IP20. Easy removal and replacement of the card facilitate maintenance and module identification during servicing.

| Parameter | Value |

|---|---|

| Model | Emerson A6740 |

| Brand | Emerson |

| Product Type | 16-Channel Output Relay Module |

| Relay Channels | 16 mechanical relays (redundant) |

| Control Voltage | 13–32 V DC |

| Contact Load | 48 V, 1 A |

| Relay Contact Type | Single Pole Double Throw (SPDT) |

| Relay Configuration | Normally open/closed selectable, energized/non-energized selectable |

| Inputs | Up to 60 inputs |

| Logical Expressions | Up to 30 |

| Module Size | 3U, 2-slot plug-in |

| Operating Temperature | 0 to 65 °C |

| Storage Temperature | -40 to 70 °C |

| Environmental Protection | IP20 |

| Shock and Vibration | Compliant with IEC standards |

| Certifications | API 670 compliant, EMC compliant |

Related Modules or Compatible Units

Emerson AMS 6500 – The core machinery health monitoring system that pairs with the A6740 relay module.

Emerson A6740-10 – A slightly narrower variant designed for different rack configurations.

Emerson A6500-RC – System relay card providing additional relay outputs.

Emerson A6910 – Configuration kit designed for use with AMS 6500 systems.

Emerson A6741 – 8-Channel input/output module complementing the relay functions.

Emerson A6360 – Power supply module used in compatible AMS 6500 racks.

Emerson A6710 – Analog input card for vibration and machinery health measurements.

Installation Notes & Maintenance Best Practices

When installing the Emerson A6740, careful consideration should be given to rack compatibility; it fits IMR6000 series racks with options for 6000/10, 6000/20, and 6000/30 versions. Adequate physical space should be ensured to allow for module cooling and easy access for maintenance. Proper grounding and shielding techniques are essential to maintain signal integrity and prevent electromagnetic interference in the sensitive machinery monitoring environment. The relay contacts require correct wiring and load matching to ensure the relays operate within specified limits.

Maintenance involves routine visual inspections of relay connectors and card seating in the rack to ensure secure mechanical and electrical connections. The module’s logic and relay states should be periodically reviewed via the AMS Suite software to verify correct operation and respond to any fault or alert indications promptly. Firmware and configuration backups are vital to maintaining system readiness. Emergency replacement modules should be kept on hand to reduce downtime in case of critical failures.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626