Description

Emerson A6500-CC 9199-00120 is a system communication card that is a critical component in the AMS 6500 ATG mechanical protection system. This single slot monitor is designed with a focus on high reliability and is suitable for the most critical rotating machinery in factories.

It serves as a communication hub and can read the parameters of all AMS A6500 ATG modules. After collecting this data, it will output these parameters through various communication protocols such as Modbus TCP/IP and Modbus RTU (serial). In addition, it also supports OPC UA for seamless transmission of data to third-party systems.

A6500-CC 9199-00120

Main features and advantages:

In the comprehensive mechanical protection system architecture, Emerson A6500-CC 9199-00120 is at the intersection of data collection and distribution. It enables operators to access mechanical health parameters in a controlled environment, facilitating seamless integration with the overall control system. This module also supplies power to the local graphic display screens on the protective rack, providing real-time machine and instrument readings. For engineers and integrators, its value lies in the ability to simplify communication infrastructure in complex industrial settings. It reduces the complexity of connecting different modules and systems, making it an ideal choice for building a complete mechanical protection monitor that complies with the API 670 standard.

From a functional perspective, the Emerson A6500-CC 9199-00120 has high-speed data processing capabilities. It can quickly read and interpret data from multiple AMS A6500 ATG modules, ensuring that operators can understand the health status of the machinery in real time. This fast data processing capability is crucial for making timely decisions, especially in situations where sudden changes in mechanical performance may lead to significant issues.

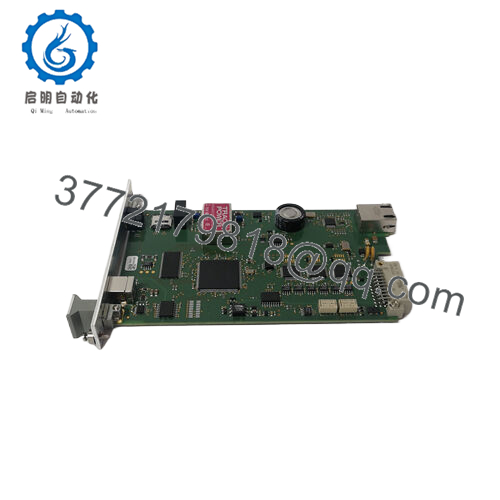

In terms of hardware design, it is a 3U sized, single slot plug-in module. This compact design is a significant advantage as it reduces cabinet space requirements by half compared to traditional 6U size cards. It also supports hot swapping, which means that in the event of a malfunction, the entire system can be replaced without shutting down. This feature complies with the API 670 standard, ensuring its reliability in industrial environments.

Compatibility is one of its prominent advantages. It can interface with various sensors commonly used in industrial monitoring, such as eddy current sensors, piezoelectric sensors (accelerometers or speedometers), seismic sensors (electric), low-frequency bearing vibration sensors, Hall effect sensors, and LVDT sensors (used in combination with A6500-LC). This broad compatibility enables it to be used in various industrial applications, adapting to different monitoring needs.

Long term reliability is guaranteed by its self inspection facilities. It continuously monitors its hardware, power input, and hardware temperature. Once any abnormalities are detected, it will issue an alert to the operator for preventive maintenance. It also includes an SD card to support the prediction function of AMS 6500 ATG, further enhancing its ability to predict potential mechanical failures and prevent expensive failures from occurring.

A6500-CC 9199-00120

Technical specifications:

Model A6500-CC 9199-00120

Brand Emerson

Type System Communication Card

Working temperature -10 ° C to+60 ° C

Installation method: Single slot installation in AMS 6500 ATG system

Interface Modbus TCP/IP, Modbus RTU, OPC UA

Certified to comply with API 670 standard

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

A6500-CC 9199-00120

Application areas:

In power plants, whether it is steam turbines, gas turbines, or hydroelectric generators, EmersonA6500-CC 9199-00120 is indispensable. For steam turbines, they can monitor key parameters related to mechanical operation. By continuously evaluating data from various sensors, it can detect signs of early wear or imbalance of turbine blades. This is crucial because any deviation from normal operation can lead to reduced efficiency, decreased power generation, and even catastrophic failures. In gas turbine based power plants, this module helps monitor the combustion process by analyzing sensor data installed at critical points. It ensures the optimal fuel air mixture ratio, thereby achieving efficient power generation and reducing emissions.

The oil and gas industry is also highly dependent on Emerson A6500-CC 9199-00120. In refineries, compressors are critical equipment that require close monitoring. This module is capable of reading all AMS A6500 ATG module parameters related to compressor operation, such as vibration level, temperature difference, and pressure changes. Through this approach, it can predict potential failures, enabling timely maintenance and avoiding costly downtime. On offshore oil platforms, the environment is harsh and equipment reliability is crucial. Emerson A6500-CC 9199-00120 can ensure the smooth operation of rotating machinery such as pumps and turbines, ensuring the safety of the entire production process.

A6500-CC 9199-00120

Installation and maintenance:

Before installing Emerson A6500-CC 9199-00120, please ensure that there are slots suitable for single slot modules in the control cabinet. The cabinet should be well ventilated to prevent modules from overheating during operation. Please carefully follow the wiring diagram provided by Emerson when connecting the module to other components in the AMS 6500 ATG system. Check for any loose connections and ensure that all cables are securely fastened.

For maintenance, conduct a visual inspection once a month. Check for any signs of physical damage to the module, such as cracks in the casing or loose connectors. Check the status indicator lights on the module to ensure they are functioning properly. Every quarter, conduct a comprehensive inspection using Emerson’s specialized diagnostic tools. These tools can help detect any potential issues with hardware, communication interfaces, or power supply. Keep the firmware of Emerson A6500-CC 9199-00120 updated to the latest version. Emerson regularly releases firmware updates, which may include bug fixes, performance improvements, and enhanced features. Updating firmware at least once a year helps maintain optimal performance of the module.

A6500-CC 9199-00120

A6500-CC 9199-00120

Other product models of EMERSON:

EMERSON 5X00500G01

EMERSON 1C31129G03

EMERSON 1C31224G01

EMERSON 1C31234G01

EMERSON 5X00453G01

EMERSON 5X00846G01

EMERSON 5X00790G01

Emerson KJ3242X1-BK1 12P4711X042

Emerson MGE-4120-CONS-0000

EMERSON A6110

Emerson FB107

Emerson OCR3000

EMERSON KJ4001X1-BE1

EMERSON NTE207-CBNS-0000

Emerson MMS6410

Emerson PR9268/202-000

Emerson 1C31189G03

Emerson XC-CPU201-EC512K-8DI-6DO

Emerson 5X00784G01

EMERSON VE3006

EMERSON VS3202

EMERSON NTE-207-CBNS-0000

EMERSON PRPMC8150-4371

Emerson VE3008 CE3008 KJ2005X1-MQ1

Emerson VE3007 KJ2005X1-BA1

Emerson PR6423/00R-000+CON021

Emerson CWM-30-08 396879-11-0S

EMERSON 1C31132G01

Emerson DA7281440

Emerson SE3008

EMERSON 4001S2T2B4 (KJ3203X1-BA1+KJ4001X1-CJ1 )

EMERSON 396563-06-6

Emerson SS4605T02

Emerson FLOBOSS S600

Emerson FLOBOSS S600+

Emerson MVME55006E-0163R

EMERSON DA7281440

Emerson DXP-L21ZNEB

Emerson A6210

Emerson ST320A-100-ASSY

Emerson A6125

EMERSON HART475

Emerson 396571-02-6

Emerson 5X00419G02

Emerson NTE-212-CONS-0000

Emerson MGM455-CONS-0000

Emerson MGE-208-CONS-0001

Emerson SS3001 KL2001X1-BB1 KL4001X1-BA1

EMERSON KJ2005X1-SQ1

EMERSON PR6424/011-140

EMERSON CON021

Emerson 701PBKKF

Emerson KL4103X1-BA1

Emerson KL2001X1-BA1

Emerson 5X00481G03

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626