Description

In the relentless arena of industrial automation, where rotating equipment like turbines, compressors, and pumps operates under extreme thermal, vibrational, and load stresses, the lack of seamless data interoperability between machinery health monitors and plant-wide control systems can blind operators to impending failures—resulting in undetected imbalances, thrust excursions, or bearing wear that escalate into multimillion-dollar outages or safety incidents. Picture a gas turbine in a combined-cycle power plant, where vibration spectra from proximity probes reveal early rotor rubs, yet siloed monitoring racks fail to relay this intelligence to the DCS in real-time, delaying ESD responses and risking API 670 non-compliance amid grid peaks. Or in a petrochemical compressor train, where temperature anomalies from accelerometers go unshared with SCADA overlays due to protocol mismatches, amplifying downtime in hydrocarbon-rich zones under IEC 61508 SIL 3 scrutiny. These gaps are pervasive in process control environments, where high reliability demands fluid data exchange to fuse I/O signals from field sensors without latency or loss, yet legacy interfaces often bottleneck with limited bandwidth or security voids, compelling engineers to deploy custom gateways or redundant networks that swell costs and complexity. Without unified communication, predictive maintenance devolves into reactive repairs, transforming asset insights into isolated islands.

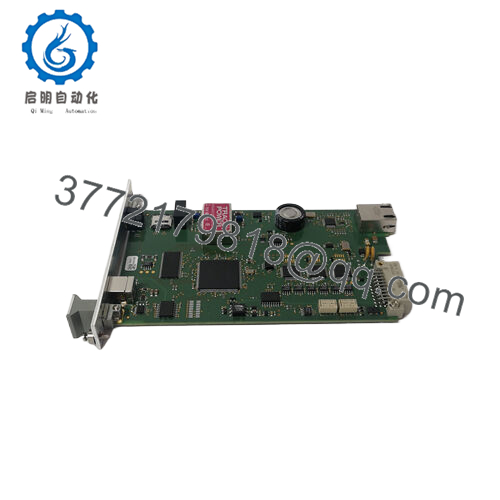

This is the connectivity chasm the Emerson A6500-CC 9199-00120 spans as a System Communication Card in the AMS 6500 ATG (Advanced Turbine Guard) machinery protection system, crafted to aggregate and export vibration, position, and diagnostic parameters with unerring fidelity. In mission-critical setups like offshore FPSO compressors or utility steam drives, it emerges as vital during health monitoring expansions, where proliferating sensor arrays from eddy-current probes or accelerometers overwhelm standalone racks; absent such a card, teams wrestle with fragmented streams that obscure trends or hinder Modbus integration. The Emerson A6500-CC 9199-00120 resides in the AMS 6500 chassis, polling data from up to 10 protection modules via the rack bus, then disseminating it over Modbus TCP/IP or RTU for DCS/PLC handoffs, complete with timestamping for event sequencing. Its cybersecurity hardening aligns with IEC 62443, ensuring encrypted flows in networked zones.

For reliability leads assessing monitoring upgrades, the Emerson A6500-CC 9199-00120 clarifies choices: it streamlines rack utilization by centralizing exports, configurable via AMS Device Manager for custom mappings, and its extreme temp tolerance (-30°C to +70°C) eases turbine hall retrofits. In rotordynamic realms where anomalies accrue exponentially, this card’s self-diagnostics preempt link failures, reframing data silos into dynamic dialogues. Whether bridging a generator’s thrust monitors or scaling a multistage pump array, the Emerson A6500-CC 9199-00120 empowers your ecosystem with the modular integration that elevates process control, blending vigilant vectoring with resilient relay to navigate machinery’s mechanical maelstroms.

Within the AMS 6500 ATG’s protective lattice, the Emerson A6500-CC 9199-00120 functions as the eloquent exporter of health harmonics, occupying a dedicated chassis slot where it taps redundant 24 VDC rails to interface with the rack’s NetCon bus, aggregating parameters like radial vibrations, axial positions, and case expansions from upstream modules. It bridges to external networks via dual Ethernet ports for Modbus TCP or RS-485 for RTU, encapsulating spectra (up to 1024-point FFTs) with 1 ms timestamps before outbound dispatch to Ovation DCS or third-party PLCs. In the I/O architecture, it perches downstream from sensor preamps—typically Bently Nevada probes—and upstream of enterprise historians, where curated datasets inform predictive algorithms or ESD voting, enabling redundancy through mirrored ports for SIL 3 fault tolerance.

- A6500-CC 9199-00120

- A6500-CC 9199-00120

What elevates its role to consultative ally is the adaptive middleware: firmware via AMS Suite tunes export rates (1-60 s intervals) and filters for cybersecurity, while SNMP alerts flag rack faults via integrated relays, quelling EMI through 1500 Vrms isolation. For a turbine’s orbital analysis, the Emerson A6500-CC 9199-00120 sequences gap voltages from X-Y probes, buffering against Ethernet floods; heartbeat diagnostics detect bus drops through LED cues. This positioning amplifies the stack’s interoperability—dovetail with A6500-UM universal cards for sensor fusion, or federate with PlantWeb for wireless extensions—while conformal shielding repels 95% RH in process steam. The Emerson A6500-CC 9199-00120 thereby coalesces as a judicious junction, where parameters propagate with preserved poise, and telemetry traces threats with prescience rather than peril.

| Specification | Details |

|---|---|

| Model Number | A6500-CC 9199-00120 |

| Brand | Emerson |

| Type | System Communication Card |

| Input Voltage | 18-36 VDC |

| Operating Temp Range | -30°C to +70°C |

| Mounting Style | AMS 6500 Chassis Slot |

| Dimensions | 10.25 x 1.75 x 8 in (260 x 44 x 203 mm) |

| Weight | 0.38 kg (170 g) |

| Interface/Bus | Rack Bus, Dual Ethernet/RS-485 |

| Compliance | API 670, IEC 61508 SIL 3, IEC 62443, CE, RoHS |

| Supported Protocols | Modbus TCP/IP, Modbus RTU, SNMP |

| Typical Power Draw | 8 W |

Incorporating the Emerson A6500-CC 9199-00120 forges a reliability fortress where protocol encapsulation averts data desyncs in hybrid networks, letting DCS loops ingest spectra within 100 ms across 100m spans—your alerts activate sans the propagation pauses that once permitted perils, all while encrypted channels thwart unauthorized probes in converged IT/OT realms. In vibration-riddled enclosures, its isolated transceivers repel coupling currents that skew exports, engineered to withstand 7g shocks without packet loss.

The husbandry paradigm orients to anticipation, as rack monitors and error latches unearth link anomalies via AMS streams, quarantining a chassis fault in logs before broadcast blight—slashing MTTR from network hunts to heuristic hints and unburdening engineering for bandwidth benchmarks over bottleneck brawls. Devised for the durance of nonstop rotations, it covenants continual cohesion through thermal-foldback circuits that adapt to 70°C loads, elevating MTBF beyond 200,000 hours while rationalizing spares to port kits. For burgeoning backbones, the Emerson A6500-CC 9199-00120‘s chassis perch hastens export infusions, eluding reconfiguration gauntlets, emancipating horizons for AI-augmented anomaly hunts on vibration veins.

Broaden the purview, and its Modbus duct pipelines purified payloads to historian havens, fusing comm vignettes with process histograms to sculpt failure fabrics preemptively. Custodians command with refined resolve, as drop alerts crystallize into navigational cues, truncating response lattices in flux glooms. Endorsing the Emerson A6500-CC 9199-00120 engenders a bridger that prognosticates passages, interweaving rigorous relay with resilient rhythm to exalt your industrial automation from disjointed to dynamically attuned.

In peaking gas turbines, the Emerson A6500-CC 9199-00120 unifies radial vibration exports and Ethernet HMIs amid fuel fluxes and thrust variances, where link lags imperil sequencing—its buffered streams secure critical system uptime, timestamping spectra in process control environments to harmonize trips without sync forfeits.

Hydro Francis runners embed it for axial position relays to IP cores, defying water hammer and silt scour; under these harsh conditions, the Emerson A6500-CC 9199-00120‘s SIL 3 failover delivers high reliability, encapsulating Modbus for glitch-free commands in fast data cycles across penstock paths.

Within cement ball mills, it aggregates bearing temp discretes and orbit analogs, with RoHS consonance suiting dust-mantled refits—port multiplicity enables unified cabinets, diminishing clutter in regulated process control environments. These panoramas laud the Emerson A6500-CC 9199-00120‘s sagacity for stewards bridging binary barriers.

A6500-RB 9199-00101 – Rack backbone module for chassis integration alongside A6500-CC communication

A6500-UM 9199-00110 – Universal measurement card companion for sensor inputs feeding A6500-CC exports

A6500-LC 9199-00115 – Low-frequency vibration card variant for bearing-focused data to A6500-CC streams

A6500-RT 9199-00105 – Rack termination board for field wiring simplification with A6500-CC

3500/15 DC 125388-01 – Bently Nevada power supply alternative for hybrid racks with A6500-CC

A6500-TA 9199-00125 – Thrust acceleration monitor add-on for axial data augmentation on A6500-CC

5X00419G02 – Ovation Ethernet link controller for DCS bridging beyond A6500-CC Modbus

A6500-ET 9199-00130 – Enclosure termination panel extending A6500-CC in remote AMS 6500 clusters

When mobilizing the Emerson A6500-CC 9199-00120 into your AMS 6500 chassis, synchronize firmware with rack rev—v2.0+ precludes encapsulation errors, per Emerson’s interoperability matrix, so an AMS diagnostic flags drifts pre-slot. Evaluate chassis convection; in >60% populated shelves, prescribe 20 CFM inlets to anchor transceivers below 65°C, and oscilloscope rails for <100 mV noise—enlisting a ferrite filter forestalls EMI echoes. Probe Ethernet ports for shield continuity, as micro-frays can inject artifacts from outset.

In incumbency, trimestral AMS scans for export skews exceeding 50 ms harmonize with card LEDs for link luminosity. Semiannually, enact protocol proofs via Device Manager—simulate a 10-module poll at 10 s intervals to affirm throughput below 200 ms—and reseat backplane latches to 0.6 Nm, sensible to warp in thermal tides. For vapor-varnished vaults, annual conformal canvasses via loupe discern delams promptly, allied with buffer pulls for anomaly arcs. These vigils interlace into rack audits, treasuring the Emerson A6500-CC 9199-00120‘s custodianship sans extravagant excursions.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626