Description

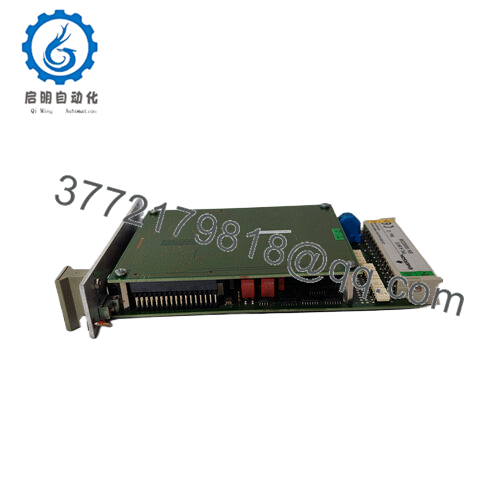

Product Model: Emerson A6410

- Brand: Emerson

- Series: Fisher/A6410 Digital Valve Controllers

- Product Type: Valve Positioner / Process Controller

- Key Features:

- Provides precise control of control valves in industrial processes

- Supports digital and electro-pneumatic control for seamless integration

- Compatible with various valve types and process systems

- Built for high reliability in harsh industrial environments

Industrial Applications and Context

Accurate valve control is essential for process safety, efficiency, and product quality. Industries such as oil & gas, chemical processing, power generation, water treatment, and manufacturing rely on digital valve controllers to ensure precise flow, pressure, and level control.

The Emerson A6410 serves as a digital electro-pneumatic valve positioner, allowing process plants to achieve high-precision control of control valves in continuous and batch processes. Its advanced diagnostics and communication capabilities help operators optimize performance, minimize downtime, and enhance safety.

- A6410

- A6410

Role of the Emerson A6410

The A6410 functions as a central control interface for valves within Emerson or compatible automation systems. Its key roles include:

- Valve Positioning: Provides precise positioning for linear and rotary valves

- Digital Control: Interfaces with DCS, PLC, and control networks for automated operations

- Feedback and Diagnostics: Monitors valve travel, position, and performance to provide predictive alerts

- Integration: Compatible with various actuators, control valves, and pneumatic systems

- System Optimization: Enhances process efficiency, reduces overshoot, and improves product quality

By delivering precise control and actionable feedback, the A6410 improves operational stability and process reliability.

Technical Features and Benefits

Core Features

- Digital Valve Positioning: High-precision positioning for control valves

- Electro-Pneumatic Control: Converts digital signals to pneumatic valve movement

- Industrial Reliability: Operates under vibration, temperature extremes, and humidity

- Communication Protocols: Compatible with HART and other standard industrial protocols

- Diagnostics: Provides valve travel, performance, and fault monitoring

- Flexible Mounting: Supports direct or remote actuator installation

- Maintenance-Friendly Design: Simplifies calibration, troubleshooting, and replacement

Benefits

- Enhanced Process Control: Provides accurate valve response for optimized flow and pressure control

- Operational Safety: Monitors valve performance to prevent misoperation and system failures

- Reduced Downtime: Built-in diagnostics enable predictive maintenance

- Versatility: Compatible with various valve types and actuator configurations

- Ease of Integration: Integrates seamlessly with Emerson DeltaV, PLCs, or other DCS systems

Technical Specifications

| Specification | Details |

|---|---|

| Model | Emerson A6410 |

| Type | Digital Valve Positioner / Controller |

| Series | Fisher / A6410 |

| Function | Provides precise control of linear and rotary control valves |

| Control Input | Digital or analog signals from DCS, PLC, or process controller |

| Output | Pneumatic actuator signal for valve positioning |

| Communication | HART protocol, other industrial protocols |

| Mounting | Direct-mount, yoke, or remote installation |

| Power Supply | 3–15 psi pneumatic input, 4–20 mA analog control signal |

| Applications | Oil & gas, chemical, power, water treatment, manufacturing |

| Diagnostics | Valve travel, position feedback, predictive maintenance alerts |

Applications Across Industries

- Oil & Gas: Provides precise control of flow, pressure, and isolation valves in pipelines and processing plants

- Chemical Processing: Monitors and adjusts valve positions for reactors, mixers, and process lines

- Power Generation: Controls turbine, boiler, and feedwater valves with high accuracy

- Water & Wastewater Treatment: Ensures accurate flow and dosing control for pumps and chemical injection

- Manufacturing: Optimizes pneumatic and electro-mechanical valve operations for automated production systems

The A6410 ensures precise valve operation and real-time feedback, which is crucial for maintaining safe and efficient industrial processes.

Installation and Maintenance Insights

Installation Guidelines:

- Install in a location with minimal vibration and environmental exposure

- Connect pneumatic and electrical interfaces according to Emerson wiring and piping standards

- Validate communication and valve positioning with control system before commissioning

- Ensure proper calibration and zeroing for accurate positioning

Maintenance Tips:

- Monitor valve travel and feedback indicators for early detection of wear or faults

- Inspect pneumatic connections and actuator interface regularly

- Perform scheduled calibration and firmware updates as recommended by Emerson

- Replace components during maintenance windows to avoid process downtime

Related Emerson Modules

- Emerson A6420: Enhanced digital valve controller with extended diagnostics

- Emerson A6430: High-performance valve positioner for severe duty environments

- Emerson 5X00273G01: I/O module for process monitoring and valve interface

- Emerson 5X00106G02: DeltaV I/O module for control and feedback integration

- Emerson FX-316: Modular I/O and process control module for DeltaV systems

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626