Description

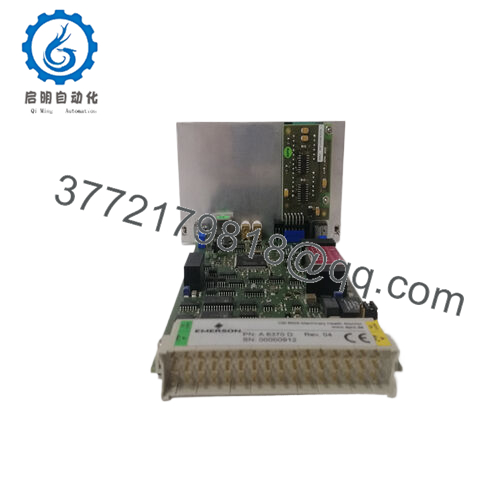

The Emerson A6370D is an overspeed protection monitor that is part of the Emerson AMS 6300 SIS (Safety Instrumented System) overspeed protection kit. It aims to become a reliable guardian of rotating machinery, providing additional security for industrial control systems. This monitor serves as a key link between sensors (used to detect speed) and control mechanisms (used to take corrective measures).

A6370D

It seamlessly integrates with various sensors such as eddy current sensors, Hall element sensors, and magnetic (VR) sensors into the control system architecture. Once speed data is received from these sensors, it will process the data and compare it with preset limits. If the speed exceeds the safety threshold, the Emerson A6370D can send a signal to trigger an alarm, initiate a shutdown procedure, or adjust mechanical operation to restore the speed to a safe level. For engineers and system integrators, its value lies in its easy integration and powerful functionality. It is easy to customize to meet different mechanical and operational requirements, making it the preferred choice for improving the safety and reliability of industrial automation settings.

A6370D

Main features and advantages:

The Emerson A6370D has excellent functional performance. Its high-speed response time enables it to instantly detect overspeed conditions. In fact, in automatic mode, its typical response time can be as low as 12.5 milliseconds, ensuring timely corrective measures are taken to protect the machinery from damage caused by excessive speed. Its accuracy is also a major advantage, with a measurement accuracy of ± 1% of the full range. This precision allows operators to set very specific speed limits and ensure that the monitor can accurately detect any deviations.

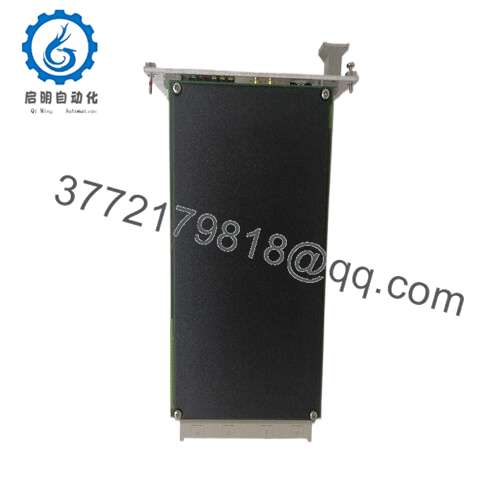

In terms of hardware design, the Emerson A6370D is durable and long-lasting. It complies with the IP20 standard, which means it can prevent pollutants from entering the air and is suitable for use in dusty industrial environments. Its size has been optimized for easy installation in a 19 inch rack. When used in conjunction with the A6371 system backplane, it has a width of 84 HP and a height of 3RU. This compact and sturdy design ensures that it can adapt to various control cabinet settings without taking up too much space.

Compatibility is another major highlight. It supports multiple communication protocols such as USB and RS-485, and for the Emerson A6370D/DP variant, it also supports Profibus DP. This enables it to seamlessly integrate with other industrial systems, whether it is the central control station or other components in AMS 6300 SIS. It also has a wide range of input options and can interface with different types of sensors, further enhancing its versatility.

Its robust electrical design ensures long-term reliability. Its nominal power supply voltage is -24.5 V ± 1.5V DC, with short-circuit protection and electrical isolation functions. This means that it can withstand electrical interference and continue to operate reliably. Its working temperature range is -20 ° C to+65 ° C, which can operate effectively in both refrigeration facilities and high-temperature industrial processing plants, providing consistent performance.

A6370D

Technical specifications:

Model A6370D

Brand Emerson

Type of overspeed protection monitoring device

Power supply -24.5 V ± 1.5V DC (short circuit protection, electrical isolation)

Working temperature -20 ° C to+65 ° C

Installation method: 19 inch rack (when used in conjunction with A6371 backplane, the width is 84 HP and the height is 3RU)

Size 211 mm x 130 mm x 43 mm

Weight approximately 490 grams

Interface USB, RS-485, Profibus DP (applicable to A6370D/DP)

Certified to comply with relevant industrial safety and quality standards

Natural convection method for heat dissipation

Environmental grade IP20

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

A6370D

Application areas:

Ensuring the safety of machinery and ensuring its optimal performance is of utmost importance in the complex industrial operation system. The Emerson A6370D overspeed protection monitor, as a key component, is widely used in multiple industries.

In the power generation industry, turbines operate at high speeds, and any deviation can lead to catastrophic failures. Emerson A6370Dcontinuously monitors the speed of these turbines.

For example, in large wind farms, the monitor closely monitors the wind turbines. If the speed exceeds the safety limit due to sudden strong winds, the Emerson A6370D will immediately trigger an alarm and activate protective measures to prevent damage to expensive turbine blades and generator components.

In the oil and gas industry, pumps and compressors are the core equipment in the production process. The EmersonA6370Dplays a crucial role in protecting these critical assets.

In refineries, it monitors high-speed compressors used to process crude oil into various products. By detecting any signs of overspeed, it helps maintain the integrity of the equipment and ensures continuous and safe operation. This not only avoids high downtime costs, but also ensures the safety of workers in hazardous environments.

In various industries such as manufacturing factories and water treatment facilities, the EmersonA6370D is an important tool for ensuring smooth and safe operation of high-speed machinery.

A6370D

Related products:

A6371- This is the system backplane designed by Emerson A6370D for use with. It provides the necessary electrical connections and communication paths for the monitor in AMS 6300 SIS.

Eddy current sensors – These sensors are highly compatible with the Emerson A6370D. They can accurately detect mechanical speed by measuring eddy currents, and the monitoring instrument can effectively process the signals received from these sensors.

Hall element sensor – Emerson A6370D can interface with Hall element sensors. These sensors can be used to detect magnetic field changes, and the monitoring instrument can convert them into speed measurements and take corresponding actions.

Magnetic (VR) sensors are key components in the Emerson A6370D sensor ecosystem. These sensors generate electrical signals based on the magnetic field of rotating machinery, and the monitoring device has been optimized to receive and analyze these signals to detect overspeed.

Relay output module – can be connected to Emerson A6370D to physically drive switches or control other devices when an overspeed event is detected. They are crucial for implementing protective measures for monitoring device startup.

Communication gateway – such as a gateway that supports different industrial protocols. They can enhance the connectivity of Emerson A6370D, enabling it to communicate with a wider range of systems and equipment in complex industrial networks.

Data acquisition module – can be used in conjunction with Emerson A6370D to collect and store speed data for further analysis. They help create historical records for predictive maintenance and performance evaluation.

Installation and maintenance:

Before installing the Emerson A6370D, ensure that the control cabinet has the appropriate size to accommodate a 19 inch rack installation. Adequate clearance should be maintained around the module to ensure proper ventilation, as overheating can affect its performance. Grounding is also a critical aspect. The module should be properly grounded to prevent electrical interference and ensure safe operation. When connecting sensors and other external devices, carefully check the wiring to ensure that all connections are secure and comply with electrical specifications.

For maintenance, it is recommended to conduct regular visual inspections. Check for any signs of physical damage, such as cracks in the casing or loose connectors. These checks can be conducted once a month to detect potential issues early. Signal diagnosis should be conducted quarterly. Use Emerson’s specialized diagnostic tool to check the integrity of signals received from sensors and the accuracy of monitor outputs. Firmware updates are also crucial. Emerson regularly releases updates to improve functionality, fix vulnerabilities, and enhance security. It is essential to stay informed of these updates in a timely manner and schedule firmware upgrades at least once a year to maintain optimal performance of the Emerson A6370D.

Other product models of EMERSON:

EMERSON 5X00500G01

EMERSON 1C31129G03

EMERSON 1C31224G01

EMERSON 1C31234G01

EMERSON 5X00453G01

EMERSON 5X00846G01

EMERSON 5X00790G01

Emerson KJ3242X1-BK1 12P4711X042

Emerson MGE-4120-CONS-0000

EMERSON A6110

Emerson FB107

Emerson OCR3000

EMERSON KJ4001X1-BE1

EMERSON NTE207-CBNS-0000

Emerson MMS6410

Emerson PR9268/202-000

Emerson 1C31189G03

Emerson XC-CPU201-EC512K-8DI-6DO

Emerson 5X00784G01

EMERSON VE3006

EMERSON VS3202

EMERSON NTE-207-CBNS-0000

EMERSON PRPMC8150-4371

Emerson VE3008 CE3008 KJ2005X1-MQ1

Emerson VE3007 KJ2005X1-BA1

Emerson PR6423/00R-000+CON021

Emerson CWM-30-08 396879-11-0S

EMERSON 1C31132G01

Emerson DA7281440

Emerson SE3008

EMERSON 4001S2T2B4 (KJ3203X1-BA1+KJ4001X1-CJ1 )

EMERSON 396563-06-6

Emerson SS4605T02

Emerson FLOBOSS S600

Emerson FLOBOSS S600+

Emerson MVME55006E-0163R

EMERSON DA7281440

Emerson DXP-L21ZNEB

Emerson A6210

Emerson ST320A-100-ASSY

Emerson A6125

EMERSON HART475

Emerson 396571-02-6

Emerson 5X00419G02

Emerson NTE-212-CONS-0000

Emerson MGM455-CONS-0000

Emerson MGE-208-CONS-0001

Emerson SS3001 KL2001X1-BB1 KL4001X1-BA1

EMERSON KJ2005X1-SQ1

EMERSON PR6424/011-140

EMERSON CON021

Emerson 701PBKKF

Emerson KL4103X1-BA1

Emerson KL2001X1-BA1

Emerson 5X00481G03

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626