Description

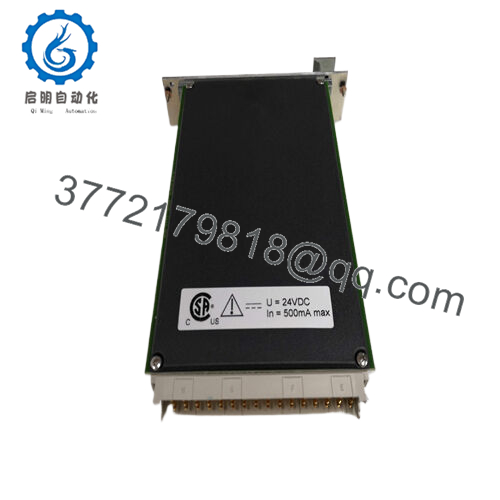

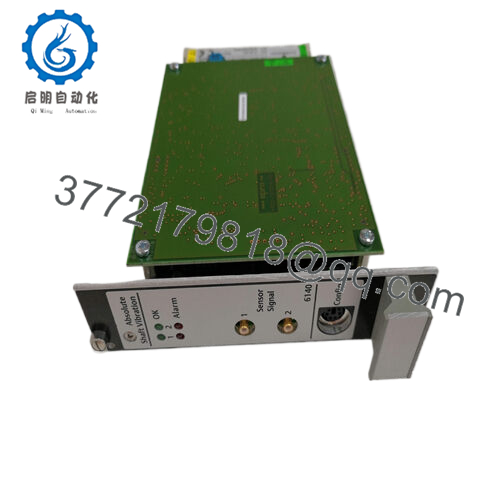

EMERSON A6140 9199-00058 is a shaft relative vibration monitoring module that is a component of the AMS 6500 mechanical health monitoring system. Emerson is a well-known brand in the field of industrial automation and control. This module is designed by Emerson to provide accurate and reliable vibration monitoring for critical rotating machinery.

A6140 9199-00058

As part of the AMS 6500 system, EMERSON A6140 9199-00058 interacts with other components in the system to provide a comprehensive view of mechanical health. It plays a critical role between sensor input and control output in industrial control architecture. This module receives input signals from Emerson eddy current and differential sensors (such as models 6422, 6423, 6424, and 6425). These sensors detect the relative vibration of the shaft and transmit data to EMERSON A6140 9199-00058.

Once the data is received, the module will use advanced algorithms for processing. Then, it provides output signals, including buffered outputs and proportional outputs (such as 0/4-20 mA and 0-10 V), which can be easily integrated into various control systems. For engineers and system integrators, this module is a valuable asset. Its compatibility with multiple sensors and control systems simplifies the setup process of mechanical health monitoring systems. It also complies with the API 670 standard, which is a widely recognized mechanical protection standard in the industry, giving users confidence in its performance and reliability.

A6140 9199-00058

Main features and advantages:

One of the most impressive features of EMERSON A6140 9199-00058 is its dual channel measurement capability. Each of the two independent channels can measure axial, radial, or tangential vibrations. This makes the evaluation of shaft vibration more comprehensive. For example, in a complex industrial machine, the shaft may experience different types of vibrations simultaneously, and the dual channel function ensures accurate capture of all aspects of the vibration.

This module also has a wide frequency range, from 0.1 to 1000 Hz. This broad frequency range makes it suitable for various industrial applications. In high-speed compressors, high-frequency vibrations may occur, and EMERSON A6140 9199-00058 can accurately measure these vibrations. On the contrary, in large, low-speed industrial fans, this module can also effectively detect low-frequency vibrations.

In terms of accuracy, the resolution of this module is 0.001 mm/s. This high-resolution measurement ensures the detection of the slightest changes in shaft vibration. It enables engineers to identify early signs of potential mechanical problems, such as the onset of bearing wear or the development of shaft imbalance.

EMERSON A6140 9199-00058 is designed to be sturdy, durable, and highly reliable. It has a sturdy structure that can withstand harsh industrial environments, including extreme temperatures, high humidity, and erosion from dust and pollutants. This makes it suitable for various industrial environments, from hot and dusty conditions in steel plants to humid and corrosive environments in coastal power plants.

Another advantage is its hot swappable design. This means that the module can be replaced or maintained without shutting down the entire industrial system. In continuous operation facilities such as power plants or chemical plants, this function is extremely valuable as it minimizes downtime during maintenance or replacement, ensuring the continuous operation of critical machinery.

A6140 9199-00058

Technical specifications:

Model A6140 9199-00058

Brand Emerson

Type: Shaft relative vibration monitoring module

Input voltage 24 VDC

Working temperature -40 ° C to+85 ° C

Installation method: 1-slot plug-in module for standard cabinet

Size 16 cm x 16 cm x 12 cm

Weight 0.8 kg

The interface is compatible with Emerson eddy current and differential sensors (models 6422, 6423, 6424, 6425); Provide front and rear buffer outputs and proportional outputs (0/4-20 mA, 0-10 V)

Certified to comply with API 670 standard

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

A6140 9199-00058

Application areas:

Taking power plants as an example, steam turbines, gas turbines, and water turbines are the core equipment of these facilities. EMERSON A6140 9199-00058 is installed on the turbine to monitor the relative vibration of the shaft. By continuously measuring and analyzing vibration levels, it can detect the minimum deviation from normal operating conditions. In steam turbines, even slight imbalances in the rotor can lead to excessive vibration, which, if not addressed in a timely manner, may cause catastrophic failures. EMERSON A6140 9199-00058 serves as an early warning system to alert operators of potential issues before they escalate.

In the oil and gas industry, compressors are widely used for transporting and processing hydrocarbons. These compressors operate under high pressure and continuous load. EMERSON A6140 9199-00058 helps monitor the vibration of the compressor shaft. Any abnormal vibration may indicate issues such as bearing wear, misalignment, or mechanical failure. By providing real-time data on shaft vibration, it enables maintenance teams to schedule timely repairs, reduce unplanned downtime, and ensure continuous transportation of oil and gas.

The manufacturing industry has also benefited greatly from this module. In factories that use large rotating machinery such as motors, pumps, and fans, EMERSON A6140 9199-00058 is used to closely monitor shaft vibration. For example, in textile factories, motors drive spinning and weaving machines. If the motor shaft starts to vibrate abnormally, it may affect the quality of the produced fabric. EMERSONA6140 9199-00058 enables manufacturers to maintain the integrity of their production processes by ensuring smooth operation of mechanical equipment.

A6140 9199-00058

Related products:

EMERSON A6141- This module has enhanced diagnostic capabilities that enable more in-depth analysis of mechanical health conditions. It can be used in conjunction with EMERSON A6140 9199-00058 to provide a more comprehensive view of shaft vibration and other mechanical parameters.

EMERSON 6422 sensor – used directly in conjunction with EMERSON A6140 9199-00058 to detect relative vibration of the shaft. It provides highly accurate input data for the module, ensuring precise vibration monitoring.

EMERSON AMS 6500 Communication Module – enables seamless communication between EMERSON A6140 9199-00058 and other components in the AMS 6500 system, as well as external control systems. It helps to efficiently transmit vibration data for further analysis and control.

EMERSON A6145- Provides additional vibration monitoring channels, which are very useful in large industrial installations that require simultaneous monitoring of more shafts. It can be integrated with EMERSON A6140 9199-00058 to expand overall monitoring capabilities.

EMERSON A6143- Featuring a more compact design, suitable for installation environments with limited space. It has some core vibration monitoring functions of EMERSON A6140 9199-00058, which can be used for small industrial applications.

EMERSON A6142- Equipped with advanced vibration data filtering algorithms. When used in conjunction with EMERSON A6140 9199-00058, it helps remove noise from vibration signals and provides clearer and more accurate data for analysis.

EMERSON A6144- This module has been optimized for high-speed mechanical equipment applications. It can work in parallel with EMERSON A6140 9199-00058, specifically designed to meet the vibration monitoring needs of rapidly rotating shafts.

A6140 9199-00058

Installation and maintenance:

It is crucial to ensure a suitable installation environment before installing EMERSON A6140 9199-00058. The cabinet where it is installed should have good ventilation conditions to dissipate the heat generated by the module. Proper grounding of the cabinet and modules themselves is crucial as it may operate in environments with electrical interference. Considering that the size of the module is 16 cm x 16 cm x 12 cm, ensure that there is enough space in the cabinet to accommodate this 1-slot plug-in module.

During the installation process, it is essential to strictly follow Emerson’s installation guidelines. When connecting sensor inputs, carefully check if the connection is secure and correctly connect to the corresponding terminals. Ensure that sensors (such as models 6422, 6423, 6424, or 6425) are correctly installed on the mechanical shaft to achieve accurate vibration detection.

For maintenance, it is recommended to conduct regular visual inspections. Check for any physical signs of damage to the module, such as cracks or loose parts. Regularly verify the integrity of sensor connections. Emerson provides software tools for calibration and diagnostic checks. It is recommended to use these tools regularly (e.g. quarterly) to ensure accurate measurement of vibration in the module. Maintain firmware updates for modules, as firmware updates typically include error fixes, performance improvements, and enhanced compatibility with other components of the AMS 6500 system.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626