Description

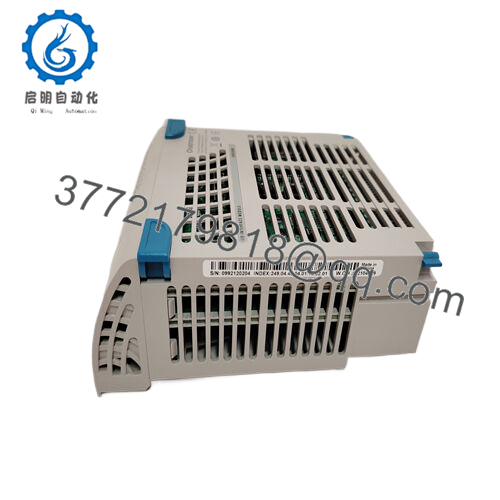

The Emerson 5X00226G04 is used extensively in industrial automation, particularly in power generation plants and process industries that utilize Emerson’s Ovation Distributed Control System (DCS). It serves as an I/O interface controller module, bridging communication between the Ovation system controllers and I/O devices in the field. This module is deployed where accurate, reliable data acquisition and control signal transmission across remote or distributed nodes are essential to maintain process stability and plant safety.

5X00226G04

5X00226G04

Industries benefit from the 5X00226G04 due to its ability to manage multiple I/O modules while ensuring seamless and high-speed communication for critical process variables. Its integration into large-scale control systems supports scalability, redundancy, and fault tolerance, helping plants optimize operational efficiency and reduce downtime.

Product Introduction and Positioning

The Emerson 5X00226G04 is an I/O interface controller designed for the Ovation platform, responsible for controlling and managing local and remote I/O modules within the distributed control framework. It converts field signals into digital data for the central controller and vice versa, ensuring data integrity and timely response to process changes.

Positioned as a core interface controller within the Ovation DCS, the 5X00226G04 complements Emerson’s modular and scalable system architecture by providing robust hardware for signal integration and communication. It facilitates high-performance control and data acquisition, essential for sophisticated process management in industries demanding precision and reliability.

Key Technical Features and Functional Benefits

The 5X00226G04 offers a compact, fanless design with low power consumption, making it suitable for installation in space-constrained control cabinets. It supports up to 16 independent I/O branches, each capable of hosting 8 I/O modules, thereby managing a large number of I/O points efficiently.

Equipped with high-speed communication ports and integrated diagnostic features, the module ensures fast and reliable data transfers and real-time monitoring of operational health. Its wide operating temperature range (-40 °C to +85 °C) enables use in harsh industrial conditions.

The module supports multiple communication protocols standard to Ovation systems, facilitating seamless integration with both legacy and modern field devices. Its robust construction and adherence to industry standards improve system uptime and reliability.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 5X00226G04 |

| Brand | Emerson |

| Product Type | I/O Interface Controller Module |

| I/O Branches Supported | Up to 16 branches, 8 modules each |

| Power Consumption | Low, fanless operation |

| Operating Temperature Range | -40 °C to +85 °C |

| Dimensions (Approx.) | 175 mm x 120 mm x 45 mm |

| Communication Interfaces | Ovation compatible protocols |

| Weight | Approx. 1.2 kg |

| Certifications | Industry standard compliance |

Related Modules or Compatible Units

5X00453G01 – Remote I/O node controller for broader I/O management.

1C31113G01 – Analog input module complementing the interface controller.

1C31194G03 – Control module supporting versatile control strategies.

1C31132G01 – Analog output module for process actuation.

A6210 – Vibration monitoring and machinery health module for integrated plant diagnostics.

Installation Notes and Maintenance Best Practices

Install the 5X00226G04 in standard Ovation cabinets with secure mounting and proper ventilation. Ensure all power and communication connections conform to Emerson’s wiring standards to reduce noise and interference. Regular inspection of hardware connections and environmental conditions helps maintain module reliability.

Perform routine diagnostics using Ovation software tools to monitor module health and performance. Schedule firmware updates and calibration checks as part of preventive maintenance to ensure ongoing operational accuracy.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626