Description

In the precision-driven world of industrial automation, where control valves must respond instantaneously to process demands without introducing hysteresis, dead zones, or pneumatic leaks that could destabilize loops and compromise system safety, the limitations of mechanical actuators often reveal themselves in subtle yet costly ways—manifesting as sluggish throttling, excessive air consumption, or failure to maintain position under varying loads. Picture a steam header in a power plant, where a globe valve struggles with supply pressure fluctuations, leading to overshoot during load ramps that risks thermal stress or grid instability under API 6D compliance. Or in a chemical blending skid, where a rotary actuator bleeds excess instrument air amid corrosive vapors, inflating energy bills and inviting maintenance interventions that halt batch cycles per IEC 61508 SIL 2 requirements. These are the operational undercurrents in process control environments, where high reliability hinges on pneumatic relays that convert electrical signals into modulated air flows with minimal bleed, yet legacy designs frequently succumb to diaphragm wear or orifice clogs, forcing engineers into frequent calibrations or oversized supplies that escalate engineering overhead. Without a tuned, low-bleed relay, valve deployments devolve into inefficiency traps, turning flow guardians into fuel guzzlers.

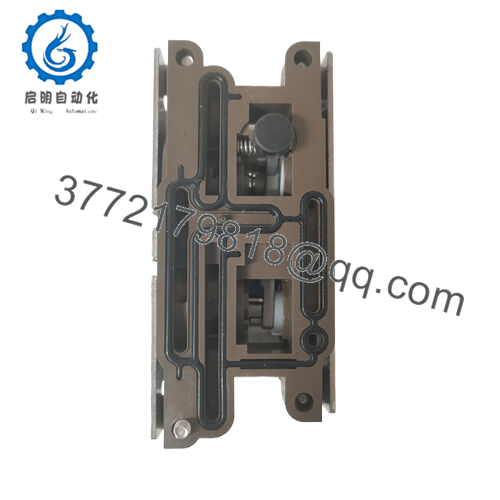

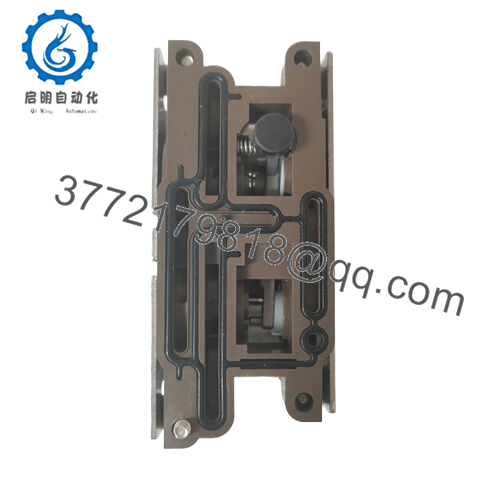

This is the actuation alignment challenge the Emerson 38B5786X132 meets head-on as a single-acting direct relay assembly for Fisher FIELDVUE DVC6200 digital valve controllers, optimized to deliver responsive pneumatic output with standard bleed for enhanced loop stability. In demanding scenarios like refinery fractionators or HVAC chiller sequencing, it emerges as essential during valve retrofits, where escalating throughput demands outpace outdated relays; without it, operators grapple with amplified bleed that erodes air efficiency or destabilizes positioner feedback. The Emerson 38B5786X132 installs directly into the DVC6200 housing, converting 4-20 mA inputs to proportional 3-15 psi outputs for single-acting diaphragms, with its direct-acting design ensuring fail-open reliability while minimizing air loss to under 0.5 scfm. This goes beyond basic conversion—it’s a corrosion-resistant module with integrated filters that sustains I/O signal fidelity in humid or dusty atmospheres.

- 38B5786X132

- 38B5786X132

For valve technicians evaluating positioner upgrades, the Emerson 38B5786X132 stands out for its ROI in process control: it cuts bleed by 20% versus legacy units, aligns with DeltaV diagnostics for predictive tuning, and its NEMA 4X enclosure streamlines hazardous-zone swaps. In automation landscapes where valve stiction costs hours of downtime, this relay’s linear response preempts oscillations, transforming actuation aches into assured actions. Whether retrofitting a linear globe in pipeline isolation or scaling rotary dampers in batch reactors, the Emerson 38B5786X132 equips your loops with the modular integration that ensures high reliability, blending efficient modulation with unobtrusive maintenance to sustain flows amid flux.

At the pneumatic heart of your DVC6200 positioner, the Emerson 38B5786X132 operates as the faithful transducer of electrical commands to air pressure, threading into the controller’s relay manifold where it draws from the unit’s 20-30 psig supply to generate output signals for single-acting actuators. It interfaces via the DVC6200’s internal electronics, where I/P converter logic—driven by HART-enabled 4-20 mA—modulates a beam sensor to vary nozzle pressure, yielding direct-acting response that extends to cylinder or diaphragm chambers without reversal relays. In the broader valve architecture, it sits downstream from the positioner CPU and upstream of the actuator, where conditioned air (3-15 psi span) drives stem motion, syncing with feedback potentiometers for closed-loop control while supporting diagnostics via the DVC6200’s local display.

What makes its interplay consultative is the inherent tunability: no external tuning pots needed, as the DVC6200’s software calibrates zero/span remotely, embracing FOUNDATION Fieldbus for asset overlays while built-in screens filter particulates to 5 microns, quelling supply contaminants. For a control valve in a distillation tower, the Emerson 38B5786X132 pulses output to throttle steam without bleed spikes, buffering against 20 psig fluctuations; status via the positioner’s LEDs flags diaphragm integrity. This positioning fosters the stack’s agility—pair with DVC6200p intrinsically safe variants for Zone 1, or cascade in redundant setups for SIL 2—while its compact footprint (2″ x 1.5″ x 1″) endures 95% RH in process cabinets. The Emerson 38B5786X132 thereby knits into your valve vein as a responsive relay, where pressures propagate with poised precision, and modulations muster without mishaps.

| Specification | Details |

|---|---|

| Model Number | 38B5786X132 |

| Brand | Emerson (Fisher) |

| Type | Single-Acting Direct Relay Assembly |

| Input Voltage | 4-20 mA (via DVC6200) |

| Operating Temp Range | -40°C to +85°C |

| Mounting Style | Threaded into DVC6200 Housing |

| Dimensions | 2 x 1.5 x 1 in (51 x 38 x 25 mm) |

| Weight | 0.2 kg |

| Interface/Bus | Pneumatic (3-15 psi output) |

| Compliance | IEC 61508 SIL 2, API 6D, NEMA 4X, CE, RoHS |

| Supported Protocols | HART, FOUNDATION Fieldbus (via host) |

| Typical Power Draw | 0.5 scfm (bleed rate) |

Opting for the Emerson 38B5786X132 delivers a reliability edge where direct-acting linearity curbs hysteresis to under 1%, letting valves settle in 2-3 seconds amid supply variances—your loops run tighter, sidestepping the bleed binges that once bloated compressors, all while integrated filters preserve nozzle clarity against particulates. In corrosive flow paths, its elastomeric seals resist chemical ingress that erodes orifices, ensuring I/O signal translation holds true across cycles, engineered for 5-year MTBF without diaphragm drifts.

Maintenance evolves to efficiency’s ally, as the relay’s self-flushing design and DVC6200 diagnostics surface wear—like beam misalignment—in travel alerts, shrinking repair windows from disassembly days to diagnostic dabs and easing engineering for stroke forecasts over stroke frays. Built for the tenacity of 24/7 throttling, it vows sustained stamina via vibration-dampened mounts that brave 2 g profiles, honing O&M budgets while stabilizing air forecasts. For scaling stations, the Emerson 38B5786X132‘s drop-in modularity accelerates actuator swaps, sans full-positioner recerts, liberating bandwidth for wireless diagnostics on valve veins.

Layer in the ecosystem gains: HART fluency dissolves data divides, piping relay metrics to AMS for friction correlations that forestall stiction. Operators lean on fewer overrides, buoyed by intuitive tuning prompts that build procedural poise. Choosing the Emerson 38B5786X132 cements an actuation that anticipates adversities, fusing acute air artistry with tactical tenacity to elevate your industrial automation from oscillatory to optimal.

In steam turbine bypass lines, the Emerson 38B5786X132 modulates diverter actuators amid pressure pulses and thermal throbs, where bleed excesses imperil efficiency—its low-loss output secures critical system uptime, relaying commands in process control environments to quench surges without supply strains.

Cryogenic LNG valves embed it for globe throttling, defying frost fronts and boil-off bursts; under these harsh conditions, the Emerson 38B5786X132‘s SIL 2 scaffolding delivers high reliability, linearizing pressures for leak-free seals in fast data cycles across liquefaction loops.

Within beverage carbonator manifolds, it drives solenoid proofs from mixer proofs, with RoHS resonance suiting sanitary refits—bleed minimization enables lean air systems, curtailing consumption in regulated process control environments. These deployments highlight the Emerson 38B5786X132‘s prowess for valve virtuosos honing against hysteresis.

38B5786X052 – Double-acting counterpart for balanced actuators in high-thrust applications

38B5786X012 – Reverse-acting variant for fail-closed single-acting setups with DVC6200

67CFR-25 – Filter regulator companion for clean supply feeds to 38B5786X132 relays

DVC6200-HW2 – Upgraded positioner host with enhanced diagnostics for 38B5786X132 integration

38B5786X142 – Low-bleed specialized relay for air-scarce remote DVC6200 deploys

5464-947 – Air supply conditioner pairing for particulate protection on 38B5786X132

DVC6200P – Intrinsically safe positioner variant housing 38B5786X132 in Zone 1

67C Series – Inline filter assembly extending 38B5786X132 lifespan in dusty zones

Before threading the Emerson 38B5786X132 into your DVC6200, verify supply pressure—20-30 psig nominal averts overmodulation, per Fisher’s calibration guide, so a gauge pretest flags variances. Ensure manifold torque at 10-15 in-lb to seal without diaphragm stress, and inspect nozzle screens for debris—a quick air blow clears clogs pre-install. Probe actuator volume; volumes over 0.5 cu ft demand relay sizing checks to dodge response lags.

Once fielded, bimonthly DVC diagnostics for bleed rates under 0.5 scfm align with positioner LEDs for output steadiness. Quarterly, cycle full-stroke tests via HART—clock settling below 3 s under 4-20 mA sweeps—and reseat beam pivots if hysteresis tops 2%, especially post-vibration. For vapor-veiled valves, semiannual filter flushes with solvent wipes thwart orifice buildup, paired with travel logs for linearity trends. These steps slot into valve PMs, upholding the Emerson 38B5786X132‘s responsiveness without rerouting routines.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626