Description

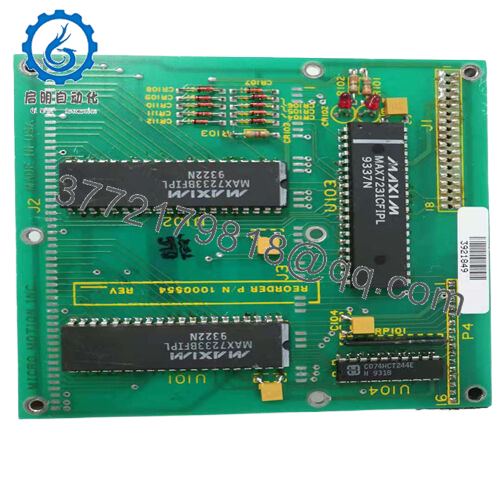

EMERSON 1000554 is a high-performance control module designed to become the core of industrial control systems. As part of Emerson’s comprehensive product portfolio of industrial automation solutions, it is designed to interact with various other components in industrial installations.

1000554

This module serves as the central hub for controlling and monitoring industrial processes. It receives input signals from sensors distributed in industrial environments, such as temperature sensors, pressure gauges, or flow meters. Then, these signals will be processed within EMERSON 1000554 according to pre programmed algorithms. Based on the processing results, it will send output signals to actuators such as valves, motors, and relays to regulate the operation of industrial equipment.

1000554

Main features and advantages:

EMERSON1000554 provides a high degree of flexibility. It can be easily customized to meet the unique needs of different industrial applications. Whether it is a small manufacturing unit or a large industrial complex, this module can be configured to optimize the performance of the control system. Its compatibility with various existing industrial systems also makes it an attractive choice for upgrading or expanding automation settings without the need for a comprehensive overhaul of infrastructure.

With advanced PID (Proportional Integral Derivative) loop tuning capabilities, it is capable of precise control of industrial processes. This means that in applications that require maintaining specific temperatures, pressures, or flow rates, EMERSON 1000554 can ensure strict adherence to set values with minimal deviation. For example, in chemical plants that require precise temperature control to ensure normal chemical reactions, this module can maintain the temperature within a very narrow range, thereby ensuring consistency in product quality.

This module also has the ability to operate for a long time under harsh industrial conditions. It has an IP67 protection rating, which means it has strong protection against dust and water. This makes it suitable for outdoor industrial environments, as well as places that may be exposed to water splashes or high humidity environments (such as certain areas of food processing plants or near cooling towers in power plants).

In terms of compatibility, EMERSON 1000554 supports multiple communication protocols. This includes industry standard protocols such as Modbus and Profibus. Therefore, it can easily integrate with other devices in industrial networks, such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other control modules. This seamless integration simplifies the overall design and implementation of industrial control systems, reducing the complexity and cost of effective communication between different components.

Its working voltage range is designed flexibly, and the input voltage range can adapt to different power sources commonly found in industrial facilities. This ensures that the module can operate reliably even in situations where there may be fluctuations in power supply. In addition, its fast response time (usually less than 1 millisecond) enables it to immediately adjust to changes in industrial processes, enhancing the system’s ability to adapt to dynamic conditions.

1000554

Technical specifications:

Model 1000554

Brand Emerson

Type control module

Power supply input: 24-240 VAC; Output: 10-120 VDC

Working temperature -40 ° C to+85 ° C

Installation method [DIN rail installation]

The interface supports communication protocols such as Modbus and Profibus

Certified CE, UL, ATEX

Protection level IP67

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

1000554

Application areas:

In the oil and gas industry, facilities operate under extreme conditions, with not only large temperature fluctuations but also potential hazardous substances present. In this environment, EMERSON 1000554 is used to regulate fluid flow, control pipeline pressure, and manage the operation of pumps and compressors. Its ability to operate reliably in such harsh environments is crucial, as any malfunction could result in significant disruptions, safety risks, and economic losses.

Manufacturing factories also heavily rely on EMERSON1000554. In the field of automobile manufacturing, it is used to control robotic arms, enabling them to assemble cars accurately and without errors. It ensures that every component can be accurately placed, reducing errors and improving the overall quality of the car. In food and beverage production, this module is responsible for maintaining strict temperature and humidity control during processing and storage, ensuring product quality, and adhering to strict quality standards.

The field of power production is also where EMERSON 1000554excels. It is responsible for managing power distribution, ensuring stable power supply to meet the needs of industry and households. By precisely controlling the operation of generators and transformers, it helps prevent power outages and voltage fluctuations, as these situations may damage electrical equipment and interfere with business operations.

Installation and maintenance:

Before installing EMERSON 1000554, careful consideration should be given to the installation environment. Ensure that the control cabinet or enclosure where it is placed has sufficient space to accommodate the module and any related wiring. The control cabinet should also be well ventilated to prevent overheating, especially when modules may operate in high-temperature environments. Grounding is crucial; Proper grounding connections must be established to prevent electrical interference and ensure the safe operation of the module.

During the installation process, it is necessary to strictly follow Emerson’s detailed installation manual for operation. Pay attention to the correct wiring of input and output connections, as incorrect wiring may cause module failure or even damage. Before installation, it is also recommended to conduct a preliminary inspection of the module to see if there are any obvious signs of damage during transportation.

For maintenance, it is recommended to conduct regular visual inspections. Check for loose connections, signs of corrosion, or physical damage to the module. Emerson provides comprehensive signal diagnostic software tools that should be used regularly to ensure that input and output signals are within the expected range. Keeping module firmware updated is also crucial. Firmware updates typically include error fixes, performance enhancements, and additional features that can improve the overall reliability and functionality of EMERSON 1000554.

Other product models of EMERSON:

EMERSON 5X00500G01

EMERSON 1C31129G03

EMERSON 1C31224G01

EMERSON 1C31234G01

EMERSON 5X00453G01

EMERSON 5X00846G01

EMERSON 5X00790G01

Emerson KJ3242X1-BK1 12P4711X042

Emerson MGE-4120-CONS-0000

EMERSON A6110

Emerson FB107

Emerson OCR3000

EMERSON KJ4001X1-BE1

EMERSON NTE207-CBNS-0000

Emerson MMS6410

Emerson PR9268/202-000

Emerson 1C31189G03

Emerson XC-CPU201-EC512K-8DI-6DO

Emerson 5X00784G01

EMERSON VE3006

EMERSON VS3202

EMERSON NTE-207-CBNS-0000

EMERSON PRPMC8150-4371

Emerson VE3008 CE3008 KJ2005X1-MQ1

Emerson VE3007 KJ2005X1-BA1

Emerson PR6423/00R-000+CON021

Emerson CWM-30-08 396879-11-0S

EMERSON 1C31132G01

Emerson DA7281440

Emerson SE3008

EMERSON 4001S2T2B4 (KJ3203X1-BA1+KJ4001X1-CJ1 )

EMERSON 396563-06-6

Emerson SS4605T02

Emerson FLOBOSS S600

Emerson FLOBOSS S600+

Emerson MVME55006E-0163R

EMERSON DA7281440

Emerson DXP-L21ZNEB

Emerson A6210

Emerson ST320A-100-ASSY

Emerson A6125

EMERSON HART475

Emerson 396571-02-6

Emerson 5X00419G02

Emerson NTE-212-CONS-0000

Emerson MGM455-CONS-0000

Emerson MGE-208-CONS-0001

Emerson SS3001 KL2001X1-BB1 KL4001X1-BA1

EMERSON KJ2005X1-SQ1

EMERSON PR6424/011-140

EMERSON CON021

Emerson 701PBKKF

Emerson KL4103X1-BA1

Emerson KL2001X1-BA1

Emerson 5X00481G03

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626