Description

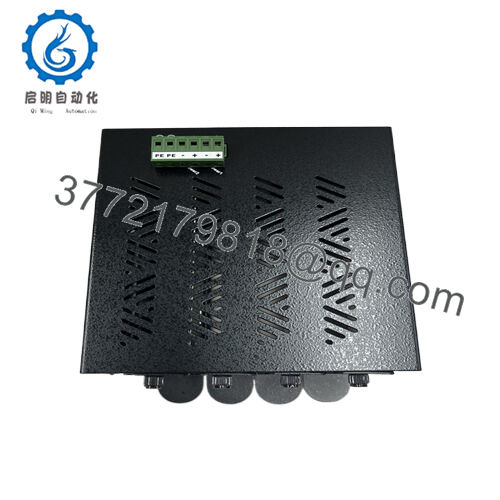

The PowerGuard EMC400-EPWS functions as an advanced electromagnetic compatibility (EMC) power conditioning unit, positioned between the facility’s main power feed and the automation control cabinet. It combines multiple protective mechanisms: surge suppression to divert voltage spikes, EMI filtering to block high-frequency noise, and voltage regulation to stabilize fluctuating input levels. This multi-layered approach ensures that the output power meets strict purity standards, compatible with a wide range of PLCs, drives, and sensors. The unit connects to the power distribution system via standard industrial terminals and integrates with building management systems through a dedicated communication port, allowing for remote monitoring of power quality metrics.

EMC400-EPWS

What distinguishes the PowerGuard EMC400-EPWS is its adaptive filtering technology, which automatically adjusts to changing noise patterns—critical in dynamic environments where machinery starts and stops frequently, creating varying EMI profiles.

EMC400-EPWS

Technical specifications:

Model Number EMC400-EPWS

Brand PowerGuard Industrial

Type EMC Power Conditioning Unit

Input Voltage 3-phase 400V AC ±10%

Operating Temp Range -10°C to +55°C

Mounting Style Floor-standing / Wall-mounted

Dimensions 350mm x 250mm x 180mm

Weight 8.5kg

Interface/Bus Modbus RTU, Ethernet/IP

Compliance CE, IEC 61000-4, UL 1449

Supported Protocols Modbus, BACnet, Profibus DP

Typical Power Draw 12W (standby), 400W (full load)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

EMC400-EPWS

Main features and advantages:

Opting for the PowerGuard EMC400-EPWS delivers tangible operational advantages that extend beyond basic power protection. Its ability to maintain consistent power quality reduces the frequency of unplanned shutdowns caused by power-related glitches, directly improving overall equipment effectiveness (OEE). Engineers benefit from reduced troubleshooting time, as power-related issues—once a common source of mystery faults—are virtually eliminated. The unit’s robust construction, including a powder-coated steel enclosure and industrial-grade components, ensures long-term performance in harsh environments, with a design life exceeding 10 years under typical operating conditions. Additionally, the PowerGuard EMC400-EPWS simplifies compliance with international EMC standards, helping facilities meet regulatory requirements for electromagnetic emissions and immunity—critical for industries with strict certification needs, such as aerospace and medical device manufacturing.

EMC400-EPWS

Application areas:

The PowerGuard EMC400-EPWS excels in applications where power integrity directly impacts process reliability. In semiconductor fabrication plants, it protects ultra-sensitive lithography equipment from voltage fluctuations that could compromise nanoscale manufacturing precision. In water treatment facilities, the PowerGuard EMC400-EPWS ensures stable power to SCADA systems and pump controllers, preventing sudden shutdowns that could lead to untreated water releases. It is also widely used in automotive assembly lines, where it safeguards robotic control systems from EMI generated by welding robots—equipment known for creating intense electrical noise that can disrupt nearby electronics. In each case, the unit’s ability to handle high power throughput (up to 400A) while maintaining low insertion loss makes it suitable for both small control cabinets and large-scale power distribution panels.

EMC400-EPWS

Related products:

EMC400-EPWS

Installation and maintenance:

Before installing the PowerGuard EMC400-EPWS, verify that the input power supply matches the unit’s voltage and phase requirements—3-phase 400V AC systems are mandatory, with no single-phase workaround. Ensure the mounting location provides adequate ventilation; the unit generates moderate heat under full load, requiring at least 300mm of clearance above and below for airflow. Check that upstream circuit breakers are sized correctly (minimum 50A) to prevent nuisance tripping during surge events.

For ongoing maintenance, inspect the unit’s status display monthly—steady green indicates normal operation, while amber alerts signal minor issues like elevated temperature. Annual preventive checks should include tightening terminal connections (to combat vibration-induced loosening) and testing surge protection components with a calibrated pulse generator. Replace surge modules immediately if the “protection degraded” indicator illuminates, as this signals reduced surge-handling capability.

Other product models:

REXROTH 4DMC160

GE 350-E-P1-G1-H-E-S-C-P-SN-D-N

Woodward 9907-135

ABB 216EA62

Emerson NTM-212-CBNS-0000

PROSOFT 5302-MBP-MCM4

AMAT SD1024F-2-S

KONGSBERG AKM32S-ASSNS-05

ABB 216EA62

ABB 216EA62

ABB 216EA62 1MRB150083R1/F

Emerson A6370D

DEIF PPU/2/GS

DELEM DM-103VA

ABB 216MB66 HESG324510M1

ABB 216NG62A HESG441634R1/K HESG216876

ABB 216NG63A HESG441635R1 HESG216879/K

ABB 216V62a HESG324442R13/B

ABB 216VC62a HESG324442R112/F

Baikale 8MSA3X.R0-30

WOODWARD 9907-014

WOODWARD 8440-2165

B&R 8MSA3X.R0-30

Emerson CE3007

ABB 216VC62a HESG324442R112/F

REXROTH HDS02.2-W040N-HS32-01-FW

Eaton XV-230-57CNN-1-13-1

WOODWARD 8405-094

ABB 216VC62a HESG324442R112/F

WOODWARD SPM-D2-10 8440-2066A

Eaton XV-440-10TVB-1-50

OMNI 6000-1D-1SE-1A-2SV

ABB 216VC62a HESG324442R13/B

ABB 216VC62A HESG324442R112/F

NI SBRIO-9627

Renishaw RLU10-A3-A3

BENTLY 3500/65-01-00 145988-02

WARNER MCS2000-ECA

WARNER MCS2000-DRV2

MECS CS-1000A

A-B 80026-529-01-R

ABB 216VC62A HESG324442R13

GE 5266222-2 – GSCB GOC6.6

LAM 810-135227-010

LAM 810-240888-002

LAM 810-107813-306

yokogawa ALP111-S001

Eaton XVH-340-57CAN-1-50

ABB 216VC62A HESG324442R13

Emerson A6125 9199-00069

Emerson A6210 9199-00003

ABB 216VC62A HESG324442R13

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626