Description

The EMC400-EPWS is used extensively in industrial automation and communication networks where reliable, flexible, and redundant media conversion is critical. This model is a 4-slot DIN-rail media converter chassis designed for challenging industrial environments where continuous network uptime is essential. It fits perfectly in control systems for manufacturing plants, utilities, transportation infrastructure, and other mission-critical industries. Its dual power input design eliminates the risk of a single point of failure by allowing two separate power sources, making it ideal for systems requiring high reliability and fault tolerance. The chassis supports seamless integration of EtherWAN media converters and Ethernet extenders, enabling effective extension and conversion of Ethernet media over long distances, which is often required in industrial automation setups to connect dispersed equipment. This makes the EMC400-EPWS especially applicable in rugged factory floors, energy grid management, and smart city infrastructures where network stability and uninterrupted communication are vital.

- EMC400-EPWS

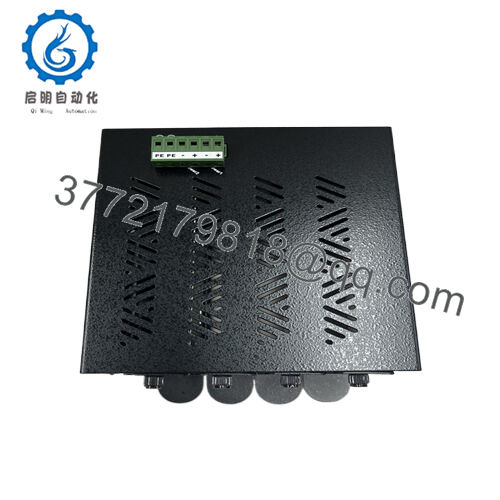

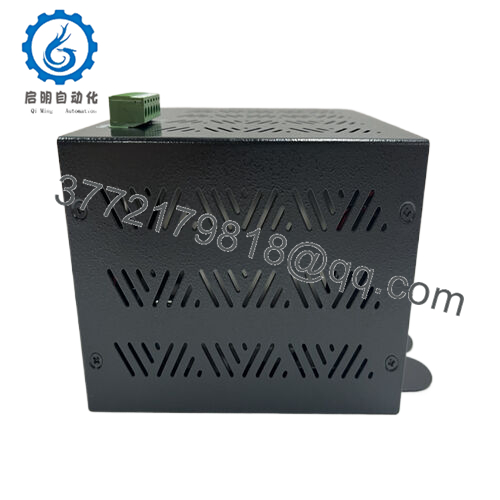

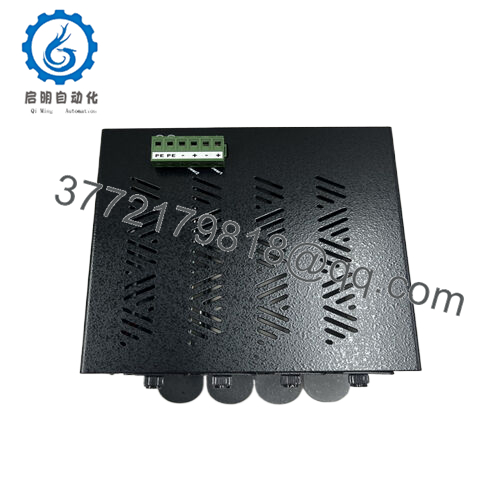

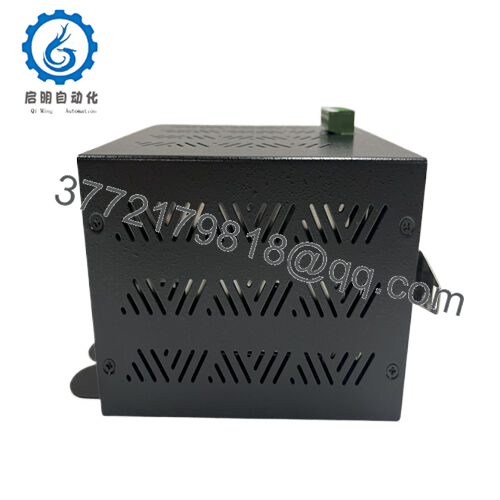

At its core, the EMC400-EPWS is a media converter chassis—a modular hardware platform that consolidates multiple media converters or extenders in one compact unit. It belongs to the EtherWAN product family and is widely compatible with EtherWAN’s range of media conversion devices, making it a versatile building block within Ethernet-based control system architectures. Positioned in the network infrastructure layer, it acts as a reliable interface between different types of communication media, typically converting fiber optic signals to copper Ethernet or vice versa. This chassis mounts on DIN rails commonly used in industrial control panels, facilitating clean and organized installation. What sets EMC400-EPWS apart is its combination of hot-swappable slots, allowing modules to be added or replaced without disrupting the network, and robust power redundancy, which engineers and integrators value highly for ensuring system resilience.

Technically, the EMC400-EPWS excels in delivering stable network uptime through its dual redundant power inputs, each powered by included HDR-30-12 power supplies. This design promotes continuous operation even if one power source fails. The chassis’ rugged metal enclosure ensures durability in the harsh conditions common in industrial environments, while its DIN-rail mounting simplifies integration into existing infrastructure. The hot-swappable slots enable on-the-fly maintenance and network expansion without downtime, a crucial feature in high-availability networks. Its compatibility extends to a broad range of EtherWAN converters and extenders, supporting various protocols and media types, thereby providing flexibility in network design. Moreover, electrical isolation and fused overcurrent protection within the chassis safeguard connected devices and the overall system from faults, improving long-term reliability and reducing maintenance incidents even under thermal or electrical stress.

| Parameter | Value |

|---|---|

| Model | EMC400-EPWS |

| Brand | EtherWAN |

| Type | 4-Slot DIN-Rail Media Converter Chassis |

| Power Supply | Dual HDR-30-12 Power Supplies included |

| Operating Temperature | 0°C to 45°C |

| Mounting | DIN-Rail |

| Dimensions | Compact for DIN-rail panels |

| Weight | Approximate industrial standard |

| Interfaces | Supports multiple EtherWAN Media Converters/Extenders |

| Certifications | Industrial compliance (specific certs vary) |

| Cooling | Passive with metal enclosure |

| Environmental Rating | Designed for industrial environments |

Related modules include EMC100 Series media converters for simpler network extensions, EMC500 Series for larger scale chassis needs, EtherWAN Ethernet Extenders for extended reach applications, HDR-30-24 Power Supplies for alternative power options, and EMC400-EP chassis without power supplies for customized configurations. Each complements the EMC400-EPWS by expanding network design flexibility or offering variations in power and capacity.

Before installation, ensure the control cabinet or rack offers sufficient DIN-rail space and proper grounding to avoid electromagnetic interference. Clearance around the chassis should allow airflow to maintain optimal operating temperature ranges. During maintenance, regularly inspect for loose connections and dust accumulation. Take advantage of the hot-swappable capability for module swaps without network downtime. Signal diagnostics should be run periodically to verify communication integrity, and firmware updates applied to media converters enhance security and performance.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626