Description

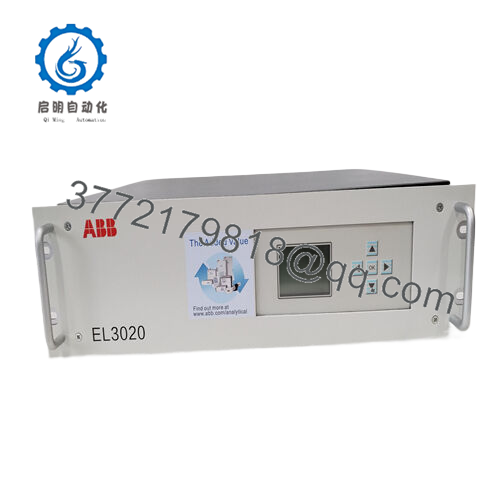

EL3020 Product Description:

EL3020 is a high-performance Ethernet communication module designed specifically for use with modular I/O systems such as Beckhoff’s TwinCAT or similar distributed control platforms. As a key component in industrial network architecture, it can serve as a master or slave device to achieve bidirectional data transmission between control systems and field devices. This module supports standard Ethernet protocols and has multiple ports, supporting daisy chain or redundant network topologies, and is suitable for linear and ring network configurations.

EL3020

TheEL3020 simplifies network design and reduces debugging time through plug and play compatibility with compatible I/O modules. Its role in automation systems is to provide a reliable physical layer for real-time control data, diagnosis, and configuration updates. The value proposition of this module lies in its combination of high-speed communication (up to 1 Gbps) with robust industrial design, ensuring stable performance in harsh environments where electromagnetic interference (EMI) or vibration may interfere with traditional serial connections.

EL3020

Main features and advantages:

High speed data transmission: The EL3020 is equipped with dual 10/100/1000 Mbps Ethernet ports (RJ45), supporting real-time data exchange cycles as low as 1 millisecond, which is crucial for applications such as motion control or high-frequency process monitoring. Its full duplex operation and support for the IEEE 802.3 standard ensure compatibility with mainstream industrial Ethernet protocols, including PROFINET, EtherCAT, and Modbus TCP.

Redundancy and Fault Tolerance: This module supports network redundancy through protocols such as PROFINET IO redundancy or EtherNet/IP Device Level Ring (DLR), minimizing downtime in the event of cable or port failures. The built-in diagnostic function can monitor link status, data throughput, and error rate, and provide real-time feedback on network health status through LED indicator lights. For example, in a pharmaceutical hybrid system, EL3020 can detect network segment failures and automatically switch to redundant paths, ensuring uninterrupted batch processing.

Scalable I/O Integration: This module can manage up to [X] I/O nodes (depending on protocol and configuration), supporting large-scale distributed systems without affecting performance. Its modular design facilitates expansion by adding additional I/O modules (such as analog inputs and digital outputs) to the same network, making it ideal for retrofitting legacy systems or expanding production lines.

Industrial grade reliability: EL3020 is designed to withstand temperatures ranging from -25 ° C to+60 ° C and vibrations up to 5 g (IEC 60068-2-6), suitable for harsh environments such as metal processing workshops or outdoor installations. The compact DIN rail installation (30mm width) optimizes the space utilization inside the control cabinet, while the reinforced connectors reduce the risk of loose connections in high vibration environments.

EL3020

Technical specifications:

Model EL3020

Brand ABB

Type Ethernet communication module

Supported protocols PROFINET, EtherCAT, EtherNet/IP, Modbus TCP, TCP/IP

Port 2 x 10/100/1000 Mbps RJ45 (automatic MDI/MDIX)

The maximum number of I/O nodes is 128 (depending on the protocol)

Data rate up to 1 Gbps

Redundancy supports network redundancy (such as PROFINET IO redundancy DLR)

Power supply 24 V DC (10-30 V DC range)

Working temperature -25 ° C to+60 ° C

Installation method DIN rail (TS 35/7.5)

Dimensions: 30mm (width) x 100mm (height) x 70mm (depth)

Weight 0.15 kilograms

Certified CE, UL, cUL, IEC 61131-2, RoHS

Environmental grade IP20, IEC 61000-6-2 (EMC compatible)

Contact Us

Mobile:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

EL3020

Application areas:

The EL3020 Ethernet link module serves as a critical interface for achieving high-speed communication between field devices and monitoring and control systems. This module is designed specifically for modular distributed I/O systems and is widely used in manufacturing factories, logistics hubs, and smart factories. It supports real-time data exchange between sensors, actuators, and programmable logic controllers (PLCs). For example, on an automotive assembly line, EL3020 can connect dispersed I/O stations (such as conveyor belt sensors, robotic gripper controllers) to a central PLC via Ethernet, ensuring synchronous operation and fast fault detection. In the warehouse automation system, it can integrate stacker cranes, automated guided vehicles (AGVs), and barcode scanners into a unified network, achieving seamless coordination of material handling processes.

This module performs well in applications that require flexible and scalable network architectures. Engineers value its ability to bridge different network protocols (such as PROFINET, EtherNet/IP) and support multiple I/O nodes, thereby reducing the need for custom gateways. For example, on food and beverage packaging lines, EL3020 can connect the remote I/O module of the monitoring filling station to the SCADA system, allowing operators to adjust parameters in real time while maintaining data integrity. By prioritizing low latency, high bandwidth, and powerful error handling capabilities, EL3020addresses the core challenge of maintaining reliable communication in complex, distributed industrial environments.

Related products:

EL1008-channel digital input module, which can be connected to EL3020, is used for discrete signal monitoring in distributed systems.

EL2008-8 channel digital output module, which controls the driving of relays or solenoid valves through EL3020.

EL3311-4 channel analog input module (± 10 V, 0-20 mA), suitable for integrating sensor data through Ethernet.

EL6731- PROFIBUS gateway module enables EL3020 to communicate with legacy PROFIBUS devices.

CX9020- Beckhoff embedded PC, serving as the system control core for network connectivity using EL3020.

FL Switch 5000- Industrial Ethernet Switch, supporting redundant ring topology with EL3020 in large networks.

Installation and maintenance:

Precautions before installation:

Plan the network topology (linear, star or ring) according to system redundancy requirements, ensuring reasonable cable routing to reduce electromagnetic interference from high-power circuits.

Use manufacturer’s software (such as TwinCAT System Manager) to configure IP addresses or device names for EL3020 and connected I/O modules to avoid network conflicts.

Ethernet connections use shielded CAT5e/CAT6 cables with shielding layers at both ends to provide optimal electromagnetic interference protection in noisy environments.

Maintenance suggestion:

Monthly network health check: Use diagnostic tools such as Wireshark or manufacturer specific software to monitor data throughput, erroneous packets, and latency.

Conduct physical inspections every quarter to verify the secure connection between Ethernet ports and power terminals, especially in high vibration applications such as conveyor systems.

Update firmware annually: Deploy the latest firmware to address security patches or protocol enhancements, and test the updates in a simulated environment before deployment.

In redundant systems, a planned failover test is conducted every six months to ensure seamless switching between the primary and backup network paths.

Other ABB product models:

ABB PM861AK01 3BSE018157R1

ABB PM633 3BSE008062R1

ABB Al630 3BHT300011R1

ABB 3BHL000986P3003 5SDF1645L0006

ABB 3BHB004744R0010

ABB 3BSE023732R1

ABB PU519 3BSE018681R1

ABB PM877 3BDH000777R1

ABB 83SR51R1210 GJR2396200R1210

ABB AO2000 LS25

ABB 1SDA053999R1

ABB CI854BK01 3BSE069449R1

ABB DI830 3BSE013210R1

ABB PM645B

ABB 3BHE035301R0001 UNS 0121 A-Z,V1

ABB 3BHE035301R1002 UNS 0121A-Z,V1

ABB AO810V2

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101

ABB XVC517AE10 3BHB004744R0010

ABB UFC760BE1042 3BHE004573R1042

ABB UFC760BE141 3BHE004573R0141

ABB NAVIGATOR 600 V20

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626