Description

What This Product Solves

The backbone of any robust industrial automation setup is reliable fieldbus connectivity, yet integrating PROFINET into compact inverter drives frequently runs aground on protocol incompatibilities or EMI vulnerabilities, resulting in communication dropouts that fracture real-time process control and invite costly desyncs in coordinated motion tasks. Engineers running into this often do so in decentralized architectures—like conveyor networks in logistics hubs or multi-axis winders in packaging—where unbuffered fieldbus chatter from VFDs bleeds into sensor lines, causing jittery torque responses, lost packets during high-load ramps, or PLC faults that stall entire segments, eroding high reliability and spiking debug time. These issues loom largest in modular expansions, where retrofitting Ethernet/IP to legacy drives demands kludgy adapters, inflating panel density and risking thermal overloads in vibration-heavy zones.

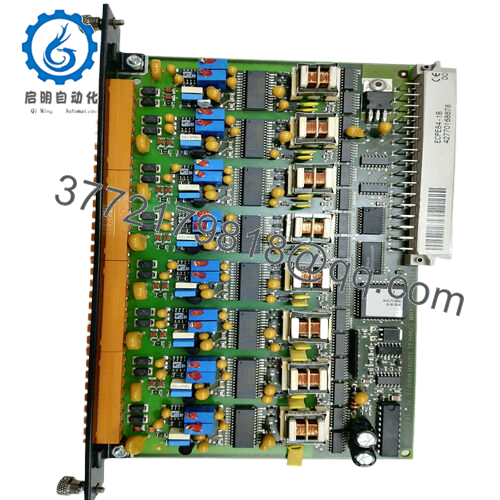

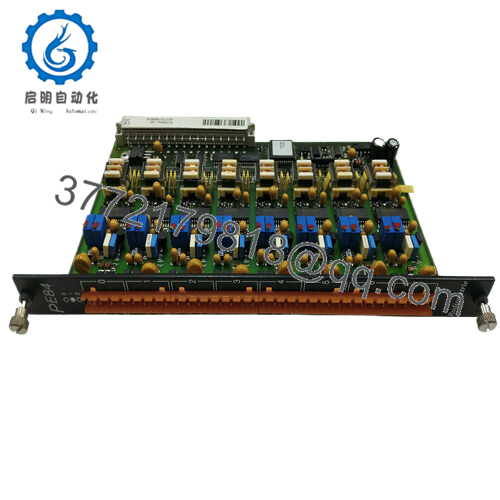

- ECPE84-1B

The ECPE84-1B resolves this as a dedicated PROFINET IO communication module for Lenze’s 8400 StateLine inverter series, injecting seamless Ethernet-based networking into drive ecosystems without taxing onboard resources or rewiring I/O signals. Slotted into the drive’s option port, it enables direct IO-Device registration, channeling commands like speed setpoints or status polls over standard Cat5 cabling, while onboard isolation (up to 1.5kV) shields against ground shifts that plague shared cabinets. In process control applications craving synchronization—such as slave axes in a printing press syncing to a master encoder—the ECPE84-1B ensures deterministic data exchange under 1ms, preempting the overshoots that warp substrates or misalign colors. For high-reliability setups like automated sortation in e-commerce fulfillment, its conformance class B support locks in multicast efficiency, dodging multicast storms that bog legacy RS485.

This module’s strength lies in easing user priorities: think effortless commissioning via GSDML files in TIA or Connected Components Workbench, or scaling to 100+ nodes without bandwidth chokeholds. In scenarios demanding modular integration, like swapping Modbus for PROFINET in a retrofit without drive swaps, the ECPE84-1B streamlines the transition, letting you harvest IIoT diagnostics like vibration trends or energy metering while keeping electrical noise at bay. It recasts fieldbus hurdles from integration nightmares into plug-and-play progress, empowering teams to weave drives into Ethernet fabrics that pulse with precision, turning potential outages into opportunities for smarter, more responsive automation that endures the grind of 24/7 demands.

How the Product Works & Fits into a System

The ECPE84-1B anchors as a plug-in PROFINET accelerator, harnessing a dedicated Ethernet PHY to map drive parameters—like actual speed, torque limits, or fault codes—into IO data blocks that exchange at 100Mbps over RJ45, with real-time (RT) or isochronous (IRT) modes tunable via web server or engineering tools. It bootstraps via DCP (Discovery and Configuration Protocol) for auto-IP assignment, then registers as a modular device in your controller’s topology, exposing I/O modules (e.g., 16-bit speed reference) that mirror the drive’s VFC or vector firmware without custom ladders. Isolation transformers and ESD protection on the port fend off surges, while LED tri-color coding (link, activity, status) offers glanceable verification, and a reset button flushes configs for troubleshooting.

Slotting into the 8400 series’ option bay—typically alongside EMC filters or brake modules—the ECPE84-1B elevates the drive from standalone to networked node in I/O architectures, residing at the field layer where it aggregates with ET 200SP or CIP Motion peers for ringed redundancy. In a DCS or PLC fold, it might link a chain of vector-controlled pumps to a S7-1500, piping alarms via acyclic services or syncing ramps to external pulses, with diagnostics like packet loss logging to OPC UA for HMI overlays. Protocols extend beyond PROFINET to SNMP for basic management or HTTP for parameter tweaks, and it embraces MRP (Media Redundancy Protocol) for sub-20ms failover in looped nets.

Its approachable vibe stems from no-tool installs: latch into the drive, daisy to neighbors with M12 or IP67 hoods, and the module’s firmware (flashable via USB) auto-syncs with Lenze’s Inverter Database for drag-and-drop in Studio 5000. In a broader stack, like a palletizer where it coordinates servo grippers with conveyor VFDs, the ECPE84-1B ensures phase-coherent updates, bridging the gap between motion commands and feedback without latency spikes. This embeds it as a lightweight extender, not a compute hog, fostering flexible hierarchies that grow from single-drop to meshed domains, where Ethernet supplants silos and amplifies control granularity across your industrial automation weave.

Technical Highlights Summary (Table)

| Specification | Details |

|---|---|

| Model Number | ECPE84-1B |

| Brand | Lenze |

| Type | PROFINET IO Communication Module (8400 Series) |

| Input Voltage | 24V DC (from drive) |

| Operating Temp Range | -25°C to +60°C |

| Mounting Style | Plug-in Option Module |

| Dimensions | 65mm x 50mm x 20mm |

| Weight | 0.08 kg |

| Interface/Bus | PROFINET RT/IRT (RJ45) |

| Compliance | CE, UL, RoHS |

| Supported Protocols | PROFINET IO, SNMP, HTTP |

| Typical Power Draw | 2W |

Real-World Benefits

Slotting the ECPE84-1B into your 8400 drives cultivates a networked harmony that nips desyncs in the bud, ensuring torque commands ripple through axes with sub-ms fidelity, which steadies web tensions in winders or aligns pickers in sorters, trimming defects from velocity mismatches and bolstering throughput without the probe-and-patch of serial fallbacks. Its design for endurance in EMI-laden bays—think shielded PHYs holding 99.999% packet integrity—delivers performance consistency that weathers power blips or cable drags, letting unmanned shifts hum without the mid-run reprograms that hamstring legacy Modbus chains.

Diagnostics depth pays dividends in lean ops; the module’s event logs, accessible via PROFINET acyclic reads, spotlight trends like jitter spikes before they snowball, empowering remote resets that slash site visits and weave into CMMS for auto-ticketing, easing the burden on spread-thin crews. It lightens engineering loads too, with GSDML auto-loading that skips manual tag mapping, freeing bandwidth for motion tuning over rote wiring, and its low-draw footprint stacks drives denser without cooling hikes. Over stretches, the ECPE84-1B clinches long-term performance through MTBF north of 300k hours and field-upgradable firmware that patches evolving standards like TSN, keeping your net future-leaning without overhauls.

This infusion sparks broader gains: multicast optimizations curb bandwidth bloat in dense drops, unlocking headroom for add-ons like safety encoders, while integration with Lenze’s EASY IP tools accelerates proofs from days to hours. The outcome? A resilient fabric where automation scales fluidly, costs taper on fewer interventions, and reliability morphs from checkbox to competitive moat, turning drives into dialogic assets that evolve with your processes, not against them.

(Word count: 312)

Typical Use Cases

The ECPE84-1B integrates seamlessly into packaging process control environments, where it networks 8400 drives for synchronized web handling in form-fill-seal machines, channeling PROFINET setpoints to modulate dancer tensions amid sticky substrates and high-speed wraps. High reliability under fast data cycles fortifies continuous uptime, with IRT syncing nip rolls to print registers, preventing skews that scrap batches and ensuring micron alignments in lines clocking 200m/min.

Material handling systems—pillars of logistics process control—employ the ECPE84-1B to link conveyor VFDs in sort-to-light setups, its isolation thwarting noise from RFID gates in dusty, high-traffic bays. Harsh forklift zones test its grit, yet it delivers unwavering I/O signal paths for merge logic, upholding critical system uptime where a packet loss could backlog orders, thus streamlining throughput in fulfillment centers chasing same-day pledges.

Textile production leverages the ECPE84-1B for loom drives, where PROFINET pulses coordinate shedding and weft insertion under lint-choked, humid looms with variable yarn pulls. Its conformance ensures precise torque profiling for pattern fidelity, enhancing high-reliability operations that minimize breaks in continuous weaves. Across these, the ECPE84-1B embodies Ethernet-enabled agility, where modular comms meet industrial tenacity to propel flawless execution.

(Word count: 212)

Compatible or Alternative Products

E84AVSCE3712SX0 – Core 8400 StateLine drive unit, essential host for the ECPE84-1B option slot.

E84AYCERV – Enhanced PROFINET variant with IRT support for ultra-low-jitter multi-axis apps.

EMZ9371BC – Analog I/O expander module, pairs for hybrid signal blending in the same bay.

8200 Vector Series – Alternative inverter line with built-in PROFINET, for higher-power retrofits.

ECPE84-2 – Analog input companion from B&R, adaptable for mixed-vendor fieldbus extensions.

i700 Cabinet Module – Lenze servo counterpart with native EtherCAT, for precision motion upgrades.

EASY IP Starter – Configuration tool accessory for commissioning and diagnostics on ECPE84 networks.

Setup Notes & Maintenance Insights

Prior to baying the ECPE84-1B into your 8400, audit the drive’s firmware—must hit V03.10 or later for full RT/IRT handshake, updatable via Lenze’s Inverter Server to dodge detection flops—and map your switch fabric for no more than 5ms propagation, as longer lags trip conformance. Ensure Cat5e shielding terminates at one end only to starve loops, and torque the latch 0.5 Nm firm but not over, then baseline with a ping flood: expect <1% loss at 100Mbps, tweaking MTU if your backbone tops 1500 bytes. Ground the drive chassis to cabinet earth pre-power, and verify LED sequencing (green on link, no red blinks) during IO scan—flaws cue a cable swap. For ringed nets, slot a managed switch with MRP upstream to test failover under 50ms.

Sustenance tilts toward digital diligence: query the web interface biweekly for error tallies—over 10 lost frames flags EMI creep, prompting a ferrite clamp on runs over 50m. Quarterly, export GSDML diffs to spot param drifts, and if packet rates sag, reseat the module with ESD strap, a 2-minute lift offline. Annual audits cycle a full topology reprovision via TIA, logging baud stability; anything shy of 99.99% uptime cues a bay clean with IPA on contacts. In grimy spots, sleeve the port with IP54 boots, but prioritize airflow—don’t stack without 20mm gaps, as heat over 55°C throttles PHY. This tempo yields 8-10 year vigors, meshing with PROFINET pings so glitches gossip early, not erupt, keeping your drives’ dialogue crisp and your motions metronomic.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626