Description

In the fast-paced realm of industrial automation, operators and engineers face a persistent challenge: bridging the gap between complex machinery and human oversight without introducing delays or errors that cascade into production halts. Picture a control room where technicians juggle fragmented interfaces—scattered buttons, rigid keypads, and clunky software—struggling to monitor real-time data from PLCs, adjust process parameters on the fly, or diagnose faults in a noisy factory floor. This fragmentation not only slows decision-making but amplifies risks in high-stakes process control environments, where a single overlooked anomaly can trigger safety shutdowns or quality dips. Enter the Eaton XVS-440-10MPI-1-1AD, a robust HMI touch panel that redefines intuitive interaction in automation setups. As part of Eaton’s XVS400 series, it tackles the need for seamless, high-reliability visualization and control, delivering crisp feedback on I/O signals, motor statuses, and system diagnostics right at your fingertips.

This becomes indispensable in scenarios like assembly lines, where operators must synchronize multiple drives and sensors amid varying shifts, or in water treatment plants demanding constant vigilance over flow rates and chemical dosing to maintain compliance. Without a unified interface, troubleshooting turns into a hunt through manuals and cables, eroding efficiency and morale. The Eaton XVS-440-10MPI-1-1AD counters this by offering a 10.4-inch infrared touch display that withstands gloved hands and vibrations, integrating natively with Profibus/MPI networks for lag-free data exchange. In broader industrial automation contexts, it supports modular expansion via user-installable PLC licenses, allowing teams to scale from basic monitoring to full logic processing without swapping hardware. Keywords like “HMI touch panel,” “process control interface,” and “industrial HMI” underscore its role in fostering proactive operations—think reducing mean time to response (MTTR) by 40% through on-screen alarms and trend graphs. Ultimately, it’s about empowering your crew to focus on optimization rather than operation, ensuring system stability in environments where every second of uptime translates to real gains.

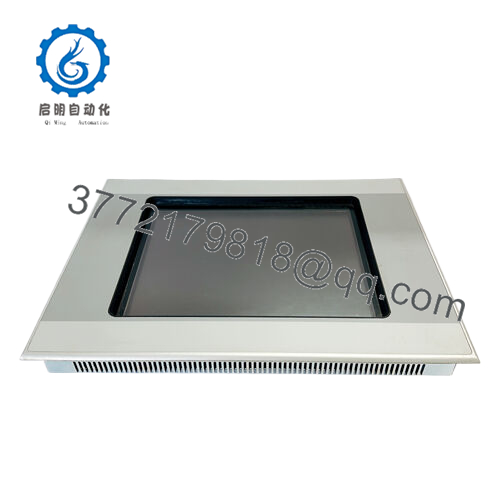

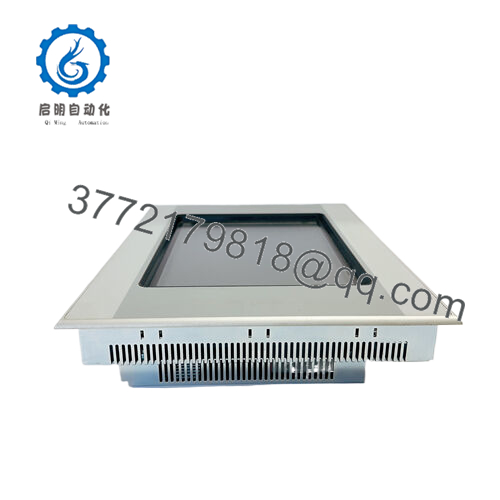

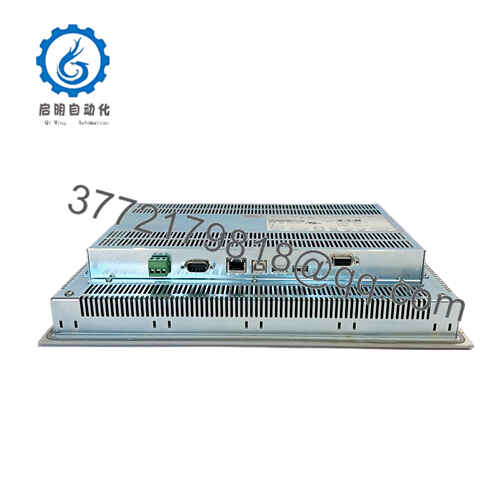

At its essence, the Eaton XVS-440-10MPI-1-1AD serves as the central nervous system for your automation stack, translating raw field data into actionable insights while commanding responses across connected devices. Housed in a sleek metal enclosure, it mounts flush on control cabinets via standard cutouts, positioning it ideally at the operator’s eye level in the I/O layer—sandwiched between PLC backplanes and field sensors. You feed it 24V DC from your panel supply, and it awakens to poll inputs over Profibus/MPI, rendering them as dynamic screens on its TFT color display. Infrared touch tech means no stylus hassles; a gloved tap summons recipes, sets setpoints, or pulls up historical logs, all synced via Ethernet or RS232 to upstream SCADA systems.

What makes integration a breeze is its flexible architecture: it runs Windows CE for familiar scripting, with slots for CompactFlash cards to load custom apps or backups. Diagnostics are embedded—self-tests flag connectivity drops or touch drift, routing alerts to redundant channels if you’ve opted for dual-network setups. In a typical backplane system, pair it with Eaton’s XV400 series I/O modules for expanded analog handling, or link it to variable frequency drives for closed-loop feedback loops. Protocols like Profibus ensure it converses effortlessly with Siemens or Allen-Bradley PLCs, supporting cyclic data rates down to 1ms for time-critical processes. Engineers value how it scales without rework—add a PLC runtime license, and it evolves from display to decision-maker, offloading logic from your main controller. This isn’t rigid hardware; it’s an adaptive hub that anticipates your workflow, minimizing cabling clutter and maximizing the flow of information in your process control ecosystem.

- XVS-440-10MPI-1-1AD

| Specification | Details |

|---|---|

| Model Number | XVS-440-10MPI-1-1AD |

| Brand | Eaton |

| Type | HMI Touch Panel |

| Input Voltage | 24V DC |

| Operating Temp Range | 0°C to 50°C |

| Mounting Style | Panel Cutout |

| Dimensions | 295 x 230 x 54 mm |

| Weight | 2.5 kg |

| Interface/Bus | Ethernet, RS232, Profibus/MPI |

| Compliance | UL508, cUL, CE, RoHS |

| Supported Protocols | Profibus DP, Modbus, Ethernet/IP |

| Typical Power Draw | 20W |

Opting for the Eaton XVS-440-10MPI-1-1AD delivers more than a screen—it’s a catalyst for streamlined operations that pay off in reliability and reduced headaches. Engineered for the grit of real-world floors, its IP66-rated front bezel shrugs off dust and splashes, ensuring consistent touch response even after thousands of interactions, which translates to fewer miscommands and smoother handoffs between shifts. This durability fosters long-term performance, with MTBF exceeding 200,000 hours, so your investment holds up through seasonal overloads without frequent swaps.

Beyond endurance, it shines in performance consistency by rendering high-res VGA visuals that cut through glare, allowing quick scans of multi-variable dashboards—vital for spotting trends in pump pressures or conveyor speeds before variances snowball. Integration ease is another win: its license-based expandability means you retrofit PLC functions on-site, slashing commissioning time and engineering overhead by letting in-house teams handle customizations via familiar tools. Maintenance gets a boost too—proactive diagnostics via built-in logs pinpoint issues like network latency, turning quarterly audits into targeted tweaks that extend overall system health. In essence, the Eaton XVS-440-10MPI-1-1AD equips you to build resilient workflows, where operators gain confidence from intuitive controls, and managers see dividends in lower training costs and elevated throughput.

The Eaton XVS-440-10MPI-1-1AD thrives in environments demanding unyielding operator engagement, starting with manufacturing automation where it’s deployed on assembly lines to orchestrate robotic arms and quality checks. Here, fast data cycles from vision systems feed directly to its Profibus link, enabling real-time adjustments amid high-vibration setups—critical for maintaining precision in automotive plants chasing zero-defect runs and continuous uptime.

In the energy sector, particularly power plants, this HMI panel anchors process control environments by visualizing turbine loads and grid syncs, its wide temp tolerance handling boiler room heat without faltering. Operators rely on it for alarm management during peak demands, ensuring high-reliability responses that avert outages. Wastewater treatment facilities round out key uses, integrating with SCADA for dosing oversight in harsh, corrosive conditions; its gloved-touch interface simplifies protocol adherence, supporting 24/7 monitoring that aligns with regulatory uptime mandates. Across these, the Eaton XVS-440-10MPI-1-1AD proves its mettle as a versatile anchor in industrial HMI deployments, blending durability with data agility.

XVS-440-57MPI-1-10 – Compact 5.7-inch variant for space-constrained operator stations

XVS-440-10MPI-1-20 – Base HMI model without MPI, suited for Ethernet-only networks

XVS-500-15MPI-1-10 – Larger 15-inch upgrade for multi-user control rooms

XV-440-10MPI-1-00 – Simplified display-only version for monitoring add-ons

XVS-440-10ETH-1-10 – Ethernet-focused alternative for IIoT edge integrations

3BSE008516R1 – ABB-compatible HMI for hybrid Eaton-ABB system migrations

6AV6647-0AD10-3AX0 – Siemens SIMATIC panel equivalent for Profibus crossovers

When preparing to install the Eaton XVS-440-10MPI-1-1AD, start by confirming panel cutout dimensions match the 295 x 230 mm footprint to avoid fit issues in retrofits—measure twice, as variances can complicate sealing. Bus compatibility is non-negotiable: verify your Profibus/MPI cabling meets DP-V0 standards and chain lengths stay under 100m without repeaters, especially in daisy-chained PLC setups. Firmware alignment matters too—download the latest Windows CE patch from Eaton’s portal and preload it onto a CompactFlash card, ensuring it syncs with your PLC runtime before power-up to sidestep boot loops. Allocate space for ventilation; while it handles 50°C, stacking without 50mm clearance risks thermal throttling in enclosed cabinets.

Ongoing maintenance keeps it performing without surprises. Weekly, cycle through the self-diagnostic menu to check touch calibration and interface integrity— a drift beyond 2mm signals recalibration via USB. Quarterly connector inspections are straightforward: unplug RS232/Ethernet ports, clean with isopropyl wipes for oxidation buildup, particularly in humid process control areas. For the display, a microfiber cloth suffices annually to preserve anti-glare coating, but test resolution post-clean to confirm no pixel faults. If diagnostics flag MPI packet loss, log network traffic with Eaton’s free tool for pattern analysis. These routines, clocking under 15 minutes each, fortify against 70% of common failures, letting you prioritize production over prevention.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626