Description

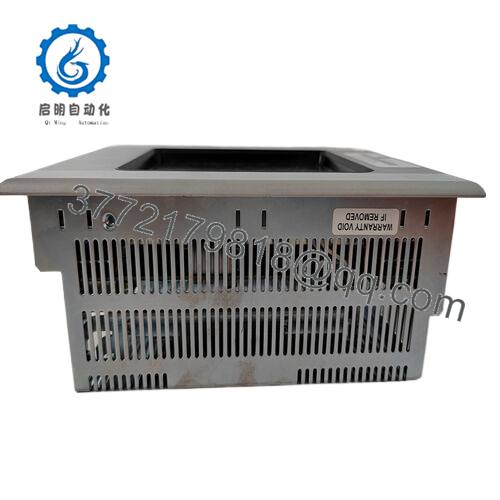

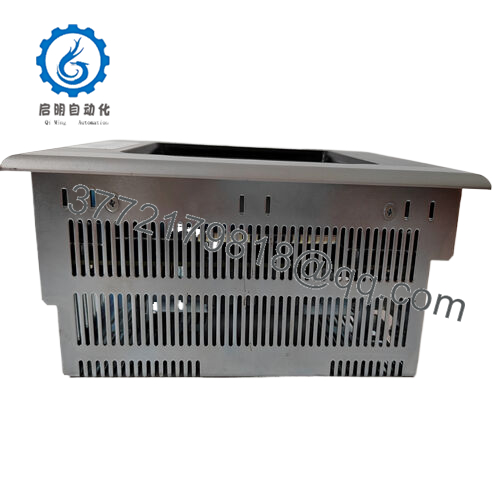

Product Model: XV-442-57CQB-1-10

- Product Brand: EATON

- Product Series: XV400

- Product Features:

• 5.7″ color CSTN display with infra-red touch interface

• Built-in communications: Ethernet, RS232, CAN / easyNet

• 24 V DC operation, compact form factor, industrial-grade design

• Optionally upgradable with PLC function via license

- XV-442-57CQB-1-10

Technical Features & Benefits

Among automation operators, the XV-442-57CQB-1-10 stands out for its flexible blend of display, communication, and optional control capacity. The 5.7-inch CSTN display (320 × 240 QVGA) gives a clear and stable visual on status panels and control screens. EATON chose an infra-red touch interface (rather than resistive), which can reduce wear on the overlay and provide a more durable, seamless front.

Connectivity is a strong point. The module includes an Ethernet interface, RS232 “system port,” and a CAN / easyNet interface out of the box. That allows direct integration into many SCADA or PLC networks without needing intermediate gateways. If you need, you can later retrofit a PLC license or expanded communications module, making the XV-442-57CQB-1-10 more than just a display terminal.

Internally, it’s backed by a 400 MHz RISC processor (typical for the XV400 line) with memory architecture supporting operating system storage (via CompactFlash) and program or data retention (NVRAM) Power-wise, it’s a 24 V DC device consuming up to ~17 W in base mode, and more when communication modules or external USB devices are active.

From a reliability viewpoint, EATON engineers built the front interface for IP65 at the front (with proper sealing), while the rear carries IP20 protection. It’s rated to operate in ambient ranges of 0 to 50 °C and can tolerate up to 95% humidity (non-condensing). Vibration and shock tolerances are in line with industrial norms (e.g. IEC 60068).

All of this means the XV-442-57CQB-1-10 is a robust option for many kinds of machine- or system-level installations, especially where tight integration and flexibility are desired.

Product Role & System Fit

In many industrial settings, you’ll find a separation between the HMI (Human Machine Interface) and the control logic (PLC). The XV-442-57CQB-1-10 blurs that boundary. At its core, it is a micro panel / HMI device in the XV400 family (5.7″ form factor), designed for visualization, operator control, and, with the right license, logic processing.

When deployed as just an HMI, it can sit in front of a PLC rack, providing screen pages, alarms, operator inputs, and data logging. But if you embed a PLC license, the same hardware becomes the control brain—eliminating a separate PLC in compact applications. That flexibility is what makes it appealing in retrofits or compact machine designs. Field technicians tell me that in tight installations, having one combined HMI/PLC module reduces wiring, cabinet footprint, and overall complexity.

Because it supports Ethernet, RS232, and CAN, the XV-442-57CQB-1-10 can talk to many legacy controllers as well as modern devices. In a factory upgrading from old systems, this module often becomes a hub, bridging new and old protocols. In process plants, you might see it handling both display of instrumentation and local interlocks or logic.

Compatibility extends to the XV400 family: expansions, software tools, and accessories used across the XV line usually apply here too. In many cases, you can migrate screen projects from one XV400 variant to another with minimal effort. In short: this is more than just a display — it’s a flexible automation part you can grow into a controller if needed.

Applications & Industry Context

Let me take you through a few real-world scenarios where the XV-442-57CQB-1-10 shines. Think packaging lines, food & beverage processing, water treatment skids, or small robotic cells. In these environments, operators need hands-on visibility and control, but often the logic footprint is modest. The 5.7″ screen is perfect in a panel door, and the infra-red touch surface resists wear in dusty or slightly humid zones.

In a filling line, for example, the XV-442-57CQB-1-10 might host recipes, display flow rates, and manage interlocks (either via external PLC or embedded license). If a bottling station has to change speeds, the operator touches the screen to select a preset, and the module sends commands over Ethernet or CAN to nearby drive controllers.

Another scenario: retrofit of older machines. Many legacy machines have analog meters or push-buttons. By replacing that with a modern HMI/PLC hybrid, engineers can modernize operator experience while preserving existing I/O wiring. The XV-442-57CQB-1-10 becomes the bridge. In wastewater control, the module could control pumps, measure levels, and provide local alarms, without needing a full PLC in tight enclosures.

In semiconductor assembly or specialty machinery, space is premium. The XV-442-57CQB-1-10 fits flush into panels and gives you a slim, neat operator station. Its broad communication support helps in integrating with higher-level SCADA or MES systems, enabling data collection or diagnostics.

From my field work, I’ve observed that many automation engineers prefer this model when they expect possible logic expansion. They install it initially as HMI, then later activate PLC features as the system evolves — avoiding hardware rework. That kind of future-proof design is precisely what gives this module long utility in changing industrial environments.

Installation & Maintenance Insights

When installing XV-442-57CQB-1-10, be mindful of cutout tolerance: the recommended panel cutout is 198 × 142 mm (±1 mm). Always insert the sealing strip correctly around the front perimeter so that no twists or gaps cause ingress. The joint of the seal should be at the bottom of the device to avoid stress. The mounting depth is modest (around 76 mm), so clearance behind the panel must be verified.

During wiring, use shielded cables especially for Ethernet and CAN segments, with proper drain grounding to the cabinet. For RS232 you must watch line length vs baud rate: e.g., at 10 m, typical max baud is 38,400 bits/s. Avoid overtightening the mounting screws — torque should stay within recommended limits (to avoid bowing the front frame).

Maintenance is relatively light. The infra-red frame can gather dust and should be cleaned periodically (especially near edges). Resistive surfaces (on other variants) may require recalibration, but for this IR touch design calibration is seldom needed. Key point: never open the housing in the field (only authorized repair centers should service the internal electronics). The internal battery (for real-time clock) is soldered and not user-replaceable.

One more tip from the field: always run a full screen backup before applying firmware updates or changing the PLC license. I’ve seen installs bricked mid-upgrade because the operator forgot to take that precaution.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626