Description

Real-World Use & Application Scenarios

In industrial environments where efficient machine operation and process monitoring are critical, the EATON XV-440-10TVB-1-20 shines as an advanced Human Machine Interface (HMI) tailored for demanding automation tasks. Widely used across industries such as manufacturing, automotive assembly, energy systems, and food and beverage processing, this versatile device empowers operators with intuitive control and real-time visualization, even under rugged conditions. The EATON XV-440-10TVB-1-20 is applicable in control systems focused on optimizing productivity by providing clear, fast feedback and seamless data exchange between operators and machines.

As an interface solution with integral PLC capabilities, it supports industrial automation setups where space is premium but computational power is non-negotiable. Its compatibility with multiple protocols like Ethernet, RS232, and CAN buses addresses challenges from integrating disparate systems to managing complex modular processes. For engineers and system integrators aiming to enhance operational safety and responsiveness, this touch panel offers reliable interaction and control in scenarios as varied as packaging lines, conveyor systems, and energy distribution control.

Product Introduction & Positioning

The EATON XV-440-10TVB-1-20 is a 10.4-inch infrared touch panel combining a vivid TFT color display with optional PLC functions, all housed within a robust metal enclosure. It is part of Eaton’s XV400 series, designed to serve as a flexible operator interface that can be retrofitted with PLC programming to seamlessly handle visualization and automation on a single compact platform.

Functioning as a key automation unit, it integrates into existing plants by providing multi-protocol communication via Ethernet, RS232, and CAN interfaces. This model enhances control architecture by allowing operators to monitor status, input parameters, and execute commands with high responsiveness. Engineers appreciate how the EATON XV-440-10TVB-1-20 facilitates system consolidation by reducing the number of separate devices required, thus simplifying wiring, reducing panel space, and improving maintainability.

Key Technical Features & Functional Benefits

The EATON XV-440-10TVB-1-20 boasts a sharp 10.4-inch TFT LCD with a 640 x 480 resolution and adjustable color depth supporting up to 65,536 colors. Its infrared touch technology allows for reliable operation under industrial conditions, including use with gloves or when exposed to dust and moisture. The screen’s laminated safety glass features a non-reflective coating enhancing usability in bright or reflective environments, an asset on busy factory floors.

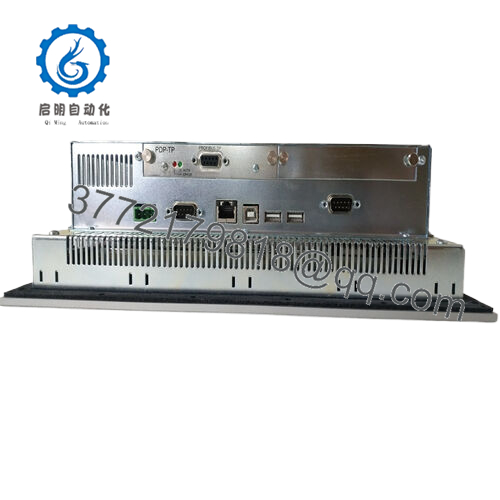

Powered by a 400 MHz 32-bit RISC processor and equipped with 64 MB onboard memory, this device provides sufficient capacity for complex control interfaces and data handling. It offers extensive connectivity through built-in Ethernet, RS232, and galvanically isolated CAN ports, with additional USB host and device ports expanding integration options further.

- XV-440-10TVB-1-20

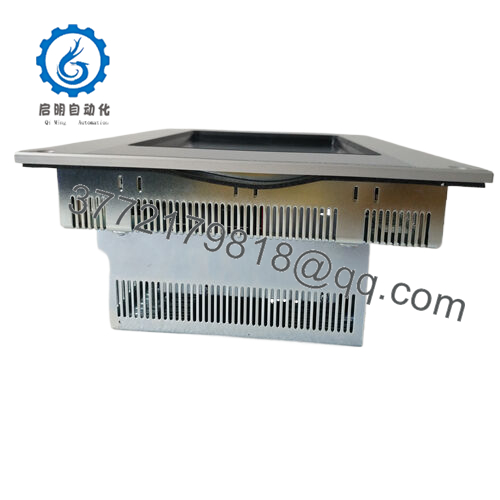

The panel supports retrofittable PLC functionality compatible with IEC 61131-3 programming languages, allowing engineers to upgrade installation capabilities according to evolving automation demands. Its stainless steel front and IP65 rating on the panel front ensure resistance to dust and water ingress, making it well-suited for harsh industrial conditions. The device operates reliably in temperatures from 0 to 50 degrees Celsius, managing heat dissipation efficiently to prolong service life.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | XV-440-10TVB-1-20 |

| Brand | EATON |

| Product Type | Touch Panel HMI with Optional PLC Function |

| Power Supply | 24 V DC (SELV) |

| Operating Temperature | 0 to 50 °C (32 to 122 °F) |

| Mounting | Flush panel mounting |

| Dimensions (WxHxD) | 345 mm x 260 mm x 93 mm |

| Weight | Approximately 4.1 kg |

| Display Type | 10.4 inch TFT color, 640 x 480 resolution |

| Touch Technology | Infrared touch |

| Interfaces | 1 x Ethernet 100Base-TX, 1 x RS232, 1 x CAN, 1 x USB Host, 1 x USB Device |

| Memory | 64 MB onboard |

| Degree of Protection (front) | IP65 |

| Certifications | UL 60950, cUL, IEC/EN 61131-2 |

| Heat Dissipation | 32 Watts |

Related Modules or Compatible Units

XV-440-10TVB-1-50 – Same 10.4-inch panel with enhanced PLC licensing options.

XV-440-12TVB-1-20 – Larger 12.1-inch display variant designed for more detailed visualization.

XV-440-10MPI-1-10 – Model with PLC already embedded, focusing more on control applications.

XV-440-10RPI-1-20 – Resistive touch technology alternative for different tactile needs.

XV-440-10TVB-X-13-1 – Entry-level color touch panel with simplified connectivity.

Installation Notes & Maintenance Best Practices

When installing the EATON XV-440-10TVB-1-20, precision in panel cutout size and flush mounting is vital to maintain the IP65 rating against dust and water. Ensure the enclosure provides sufficient internal ventilation for heat dissipation as the device consumes up to 32 watts, which could affect ambient temperatures in compact cabinets. The recommended power supply voltage tolerance and grounding practices must be observed to mitigate electrical noise and maintain communication stability.

Routine maintenance includes cleaning the laminated safety glass with non-abrasive agents to sustain touch sensitivity and screen clarity. Regular checks on cable terminations and communication ports reduce connectivity faults. Firmware and software updates through USB or Ethernet help enforce performance improvements and security patches. Monitoring device diagnostics through software tools facilitates early fault detection, streamlining preventive maintenance procedures.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626