Description

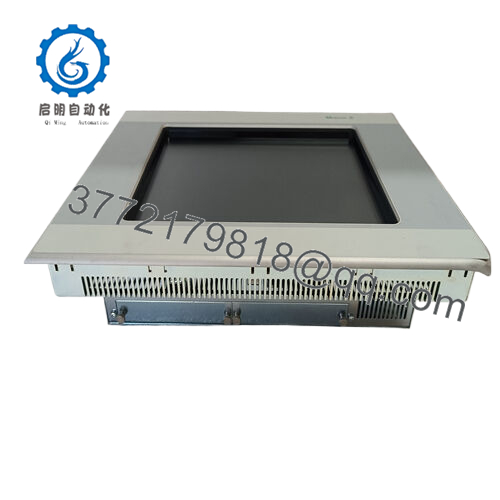

In the relentless grind of industrial automation, where split-second decisions hinge on clear visibility into complex processes, operators often contend with interfaces that lag, glitch, or obscure critical data under pressure. Envision a bustling packaging facility: lines churning at full tilt, sensors feeding frantic streams of temperature, speed, and pressure readings, yet the control panel freezes or delivers washed-out visuals, forcing frantic reboots and halting output for precious minutes. This visibility gap not only erodes throughput but invites errors in process control, escalating from minor delays to safety incidents or compliance lapses in environments demanding unerring precision. The Eaton XV-440-10TVB-1-13-1 emerges as a steadfast countermeasure—a 10.4-inch TFT color display panel from Eaton’s XV400 series, optimized for delivering sharp, reliable visualizations in high-stakes HMI applications. It bridges the chasm between raw I/O signals and human intuition, rendering live trends, alarms, and schematics with fidelity that keeps teams ahead of anomalies.

Such panels prove vital in setups like food and beverage processing, where hygiene standards mandate splash-proof enclosures and rapid recipe switches, or in pharmaceutical batching, where traceability logs must withstand audit scrutiny without data loss. Absent this level of clarity, debugging a stalled conveyor becomes a scavenger hunt across disparate logs, inflating mean time to repair and straining resources. The Eaton XV-440-10TVB-1-13-1 integrates effortlessly into modular I/O architectures, supporting high-reliability data flows via serial and Ethernet protocols to cut through the noise of electromagnetic interference or vibration. In the lexicon of industrial automation, terms like “TFT display panel,” “HMI visualization,” and “process monitoring interface” capture its essence: a tool that empowers predictive oversight, slashing unplanned stops by enabling on-the-fly adjustments. It’s less about replacing old screens and more about reclaiming control, fostering environments where stability isn’t hoped for but engineered in, and every operator glance yields actionable intelligence.

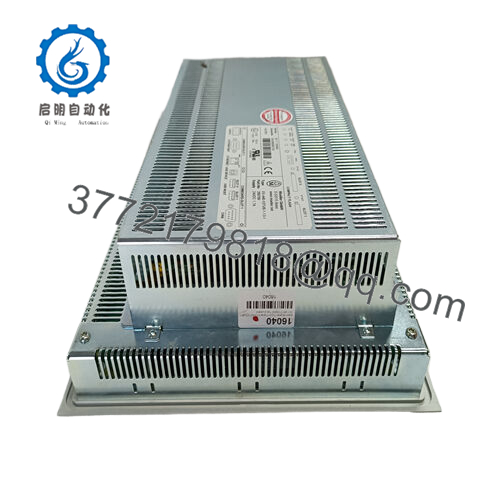

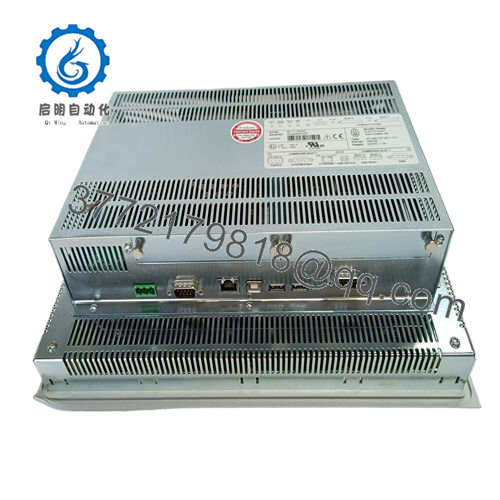

Delving into its operational core, the Eaton XV-440-10TVB-1-13-1 acts as a vigilant window into your automation framework, perched at the operator layer to distill field-level chaos into coherent, color-coded narratives. It slots into control enclosures via straightforward panel cutouts, drawing 24V DC from the cabinet bus while interfacing with PLC backplanes through RS232/485 or Ethernet ports—ideal for daisy-chaining in distributed setups. Once powered, its 800×600 VGA resolution TFT screen ignites, pulling cyclic updates from Modbus or Profinet networks to plot real-time graphs of analog inputs, like valve positions or flow metrics, without taxing the main controller.

- XV-440-10TVB-1-13-1

- XV-440-10TVB-1-13-1

Integration feels intuitive rather than imposed: configure via USB or CompactFlash for custom bitmaps and scripts, and it syncs diagnostics to redundant paths, alerting via on-screen pop-ups if a channel drops. In the broader stack, envision it upstream of actuators and downstream of sensors, buffering data in volatile zones like welding bays where arcs spike interference. Its resistive touch overlay—though absent in this display-only variant—relies on precise cursor navigation for menu dives, but the real magic lies in protocol agility, handling up to 100Mbps Ethernet bursts for seamless handoffs to SCADA overlays. For redundancy, it supports mirrored outputs to secondary monitors, ensuring failover in mission-critical loops. Engineers deploying it in backplane-heavy systems praise the minimal footprint; no exotic tools needed—just align the mounting clips, seal the IP65 front against ingress, and watch it harmonize with Eaton’s XV series expansions. This positioning transforms it from peripheral viewer to pivotal informant, streamlining the flow from raw signals to refined decisions in your process control tapestry.

| Specification | Details |

|---|---|

| Model Number | XV-440-10TVB-1-13-1 |

| Brand | Eaton |

| Type | TFT Color Display Panel |

| Input Voltage | 24V DC |

| Operating Temp Range | -20°C to +60°C |

| Mounting Style | Panel Cutout |

| Dimensions | 280 x 216 x 50 mm |

| Weight | 2.8 kg |

| Interface/Bus | RS232/485, Ethernet |

| Compliance | UL508, CE, RoHS, IP65 Front |

| Supported Protocols | Modbus RTU/TCP, Profinet |

| Typical Power Draw | 18W |

Selecting the Eaton XV-440-10TVB-1-13-1 unlocks a cascade of operational edges, foremost among them the rock-solid reliability that turns fleeting data into enduring insights. Crafted to endure the punishing cycles of factory life, its anti-glare TFT surface maintains vibrancy through oily fingerprints or steam exposure, delivering consistent 16M-color depth that reveals subtle shifts in waveforms—crucial for preempting overloads in compressor banks before they spike. This isn’t mere endurance; it’s the foundation for sustained performance, with thermal safeguards that throttle only as a last resort, preserving clarity in temps swinging from chill storerooms to sun-baked rooftops.

The payoff extends to efficiency gains, as its protocol versatility weaves effortlessly into mixed-vendor landscapes, obviating the need for protocol converters and trimming integration timelines by weeks. Maintenance crews benefit from embedded health checks that log pixel integrity and connection stability, enabling swap-free runs that stretch beyond five years without dimming. In use, this eases the burden on engineering teams—deploy it to visualize legacy analog loops alongside digital twins, reducing custom coding and fostering a unified view that accelerates root-cause analysis. Long-haul, the Eaton XV-440-10TVB-1-13-1 cultivates a culture of foresight: operators intuit issues from glanceable mimics, managers track KPIs without sifting spreadsheets, and the whole system hums with fewer interventions, channeling resources toward innovation over upkeep.

At its heart, the Eaton XV-440-10TVB-1-13-1 bolsters resilience in sectors where visual acuity directly safeguards assets and output. Deployed in chemical processing plants, it monitors reaction vessels via Ethernet-linked probes, its wide temp resilience holding firm amid exothermic heats to flag pH drifts in real time, upholding critical system uptime against volatile feeds. In automotive manufacturing, this display anchors weld cell oversight, rendering high-fidelity scans of seam integrity from camera feeds, where vibration-proof mounting ensures steady views during 24/7 shifts.

Pivoting to logistics hubs, it’s a staple for sortation controls, projecting throughput metrics and jam alerts on overhead panels to guide floor teams through peak volumes without halting belts. These vignettes underscore its adaptability: in corrosive process control environments or dust-choked warehouses, the Eaton XV-440-10TVB-1-13-1 stands as the unflinching eye of industrial HMI, championing precision where lapses cost dearly and reliability redefines readiness.

XV-440-10TVB-1-10 – Base display model with standard RS232 for legacy serial integrations

XV-440-15TVB-1-10 – 15-inch upscale for expansive dashboard views in control rooms

XVS-440-10MPI-1-1AD – Touch-enabled counterpart for interactive operator commands

XV-440-10ETH-1-10 – Ethernet-only variant optimized for networked SCADA uplinks

XV-400-4TVB-1-10 – Compact 4-inch option for localized machine-side monitoring

XV-440-10TVB-1-20 – Enhanced brightness edition for outdoor or high-ambient light setups

6AV6647-0AB00-3AX0 – Siemens HMI equivalent for cross-platform protocol bridging

Prior to committing the Eaton XV-440-10TVB-1-13-1 to your panel, audit the cutout specs—standard 258 x 195 mm—to preempt alignment snags, particularly in legacy enclosures where tolerances have wandered. Protocol matching warrants a close look: confirm Modbus baud rates align with your PLC’s RS485 settings, and cap segment lengths at 1200m to dodge signal attenuation in sprawling layouts. Firmware currency is non-optional; snag the newest from Eaton’s site and flash via Ethernet before first boot, as mismatches can lock out remote access. Ventilation clearance of at least 75mm above and below mitigates hotspot risks in stacked arrays, especially given the -20°C to +60°C envelope.

Maintenance protocols keep it vigilant without excess effort. Bi-monthly, invoke the built-in test suite through the service menu to validate color calibration and port handshakes—a five-minute ritual that catches drift early. Semi-annually, inspect bezel seals for cracks under UV light if in washdown zones, resealing with silicone if gaps exceed 0.5mm to preserve IP65 integrity. For cabling, tug-test Ethernet jacks quarterly in vibration-prone spots, swapping ferrules if resistance climbs above 1 ohm. Annual deep dives involve archiving display logs to USB for trend review, spotting patterns like intermittent blackouts tied to power flux. These measures, grounded in field realities, sideline most degradation, ensuring the Eaton XV-440-10TVB-1-13-1 remains a clear conduit for your automation narrative.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626