Description

Product Model: E84AHWMC1534V-V003

Product Brand: Lenze

Product Series: 8400 HighLine

Product Features:

- High-performance inverter for asynchronous and synchronous motors

- Integrated positioning and communication capabilities

- Compact modular design for flexible installation

- Optimized energy efficiency and precise motor control

Applications & Industry Context

In today’s automation landscape, efficiency and adaptability define competitiveness. The E84AHWMC1534V-V003 frequency inverter from Lenze’s 8400 HighLine series delivers both. Found in conveyor systems, packaging machines, material handling, and energy-efficient manufacturing processes, this drive is engineered for reliability and performance in motion-intensive applications.

In a typical packaging plant, the E84AHWMC1534V-V003 controls conveyor belts, ensuring smooth acceleration and deceleration to prevent product spillage or jamming. In automated storage and retrieval systems, it synchronizes multiple drive axes, maintaining consistent movement across lifts, shuttles, and carousels.

Energy efficiency plays a vital role in modern operations, and this drive is designed with that in mind. Many users report measurable reductions in power consumption after upgrading legacy drives to the E84AHWMC1534V-V003, thanks to its optimized vector control and integrated energy-saving functions.

In machine-building, OEMs appreciate its scalability. The 8400 HighLine series offers a consistent software and hardware platform across power ranges, allowing engineers to reuse configurations and reduce development time. For process industries, the drive’s robust performance in variable-load conditions ensures consistent torque and speed regulation — a key factor in maintaining process quality.

Whether installed in a bottling line in Germany or an automated warehouse in Singapore, the E84AHWMC1534V-V003 consistently demonstrates why Lenze remains one of the most trusted names in industrial motion control.

- E84AHWMC1534V-V003

Technical Features & Benefits

The E84AHWMC1534V-V003 isn’t just another frequency inverter — it’s a finely tuned control system engineered to deliver precision, reliability, and intelligence to your motor-driven processes.

1. Advanced Motion Control

At the core of this inverter is Lenze’s vector control technology, enabling both open-loop and closed-loop operation. It provides accurate torque and speed regulation even under dynamic load changes. This makes the E84AHWMC1534V-V003 ideal for demanding mechanical applications requiring synchronization, positioning, or smooth speed ramps.

2. Integrated Intelligence

The drive supports positioning functionality directly on board — eliminating the need for external motion controllers in many applications. With integrated PLC-like logic, engineers can implement sequence control directly in the inverter, simplifying system design.

3. Communication Flexibility

Connectivity is another hallmark. The E84AHWMC1534V-V003 supports major fieldbus and industrial Ethernet protocols, including CANopen, EtherCAT, and PROFIBUS, depending on the configuration. This flexibility ensures seamless integration with PLCs from Siemens, Beckhoff, Mitsubishi, and others.

4. Compact, Modular Design

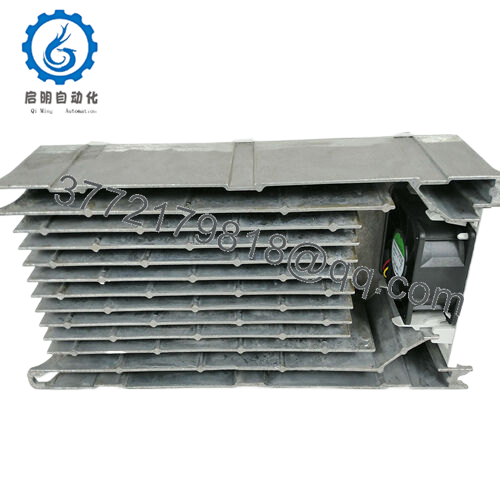

Designed with panel builders and integrators in mind, the HighLine series features a compact housing and modular structure. Mounting and wiring are simplified, and cooling concepts allow installation in tight spaces without overheating issues.

5. Energy Efficiency & Longevity

Built-in DC bus connections enable energy sharing between drives — capturing regenerative energy from braking motors and redistributing it, which enhances efficiency. The E84AHWMC1534V-V003 also includes advanced diagnostics and temperature monitoring, extending motor and drive life.

6. Safety Integration

Safety is not an afterthought. The model supports Safe Torque Off (STO), compliant with EN ISO 13849-1 PL d and SIL 2. This ensures reliable stopping without requiring external safety relays, reducing wiring complexity and cost.

7. User-Friendly Commissioning

Using Lenze’s Engineer software, parameter setup and tuning are straightforward. Graphical wizards guide users through configuration, and diagnostic tools help fine-tune system performance in real-time.

For engineers who value precision and reliability, the E84AHWMC1534V-V003 combines control finesse with practical usability — a signature of Lenze’s engineering philosophy.

Technical Specifications

| Specification | Description |

|---|---|

| Model | E84AHWMC1534V-V003 |

| Brand | Lenze |

| Series | 8400 HighLine |

| Type | Frequency Inverter / Variable Frequency Drive |

| Rated Power | 1.5 kW |

| Input Voltage | 3 × 400/480 VAC (±10%) |

| Output Current | 3.4 A |

| Frequency Range | 0–500 Hz |

| Control Method | V/f, Sensorless Vector, Servo Mode |

| Communication Options | CANopen, EtherCAT, PROFIBUS (optional) |

| Safety Function | Safe Torque Off (STO) integrated |

| Protection Class | IP20 |

| Cooling Method | Forced Air Cooling |

| Mounting | Book-style, side-by-side |

| Ambient Temperature | 0°C to +55°C (derating above 45°C) |

| Dimensions (H×W×D) | 270 × 90 × 195 mm |

| Weight | Approx. 3.4 kg |

| Compliance | CE, UL, cUL, RoHS |

Installation & Maintenance Insights

Installing the E84AHWMC1534V-V003 is a straightforward process, but correct preparation ensures long-term reliability. The drive’s slimline “book-style” design allows for side-by-side mounting in control cabinets, saving valuable space. Ensure adequate airflow — at least 50 mm clearance above and below — to maintain cooling efficiency.

Before wiring, verify grounding continuity and check that the supply voltage matches the inverter’s rated input. Lenze’s pluggable terminal concept simplifies connection of power and control wiring, minimizing downtime during installation or replacement.

Parameter setup is easily accomplished through the Lenze Keypad XT or the Engineer software on PC. For quick duplication, settings can be copied between drives using the memory module — an invaluable feature for machine builders who standardize multiple systems.

Routine maintenance is minimal. Periodic dust cleaning and fan inspection help sustain cooling efficiency. The E84AHWMC1534V-V003 provides built-in thermal protection and diagnostic messages, making preventive maintenance intuitive.

In the field, technicians appreciate its modularity: replacing fans or option cards doesn’t require complete disassembly. Combined with Lenze’s reliable global service support, downtime is reduced to a minimum.

Product Role & System Fit

Within the automation hierarchy, the E84AHWMC1534V-V003 plays a central role in motor control and motion coordination. It serves as the interface between the electrical supply and the mechanical system, managing energy conversion, torque, and speed in precise harmony.

In distributed automation setups, it’s often networked via EtherCAT or CANopen, communicating directly with PLCs or master controllers. The built-in motion control functions mean it can execute positioning tasks locally, freeing up higher-level systems and improving response times.

Its power range and performance make it well-suited for mid-scale machinery — conveyors, pumps, fans, and indexing systems. In multi-axis configurations, several E84AHWMC1534V-V003 units can share a DC bus, enabling energy-efficient operation with regenerative braking and dynamic load balancing.

System integrators favor its compatibility and ease of commissioning. Whether paired with Lenze’s 9400 Servo systems or integrated into Siemens TIA environments, the drive maintains seamless communication. That flexibility reduces integration complexity and future-proofs automation systems.

Related Models

- E84AVSCE7514SX0 – Compact 0.75 kW inverter for smaller drives

- E84AVHCE2224SX0 – 2.2 kW variant with enhanced overload capability

- E84AHHCE5524SX0 – 5.5 kW model for larger conveyor or pump applications

- E84AZSCE1524SX0 – Servo-rated model for dynamic control needs

- E84AVSCE3714SX0 – 0.37 kW unit for low-power, high-efficiency systems

- E84AHHCE7514V – 7.5 kW high-torque inverter for demanding loads

- E84AVSCE1124SX0 – 1.1 kW model with compact footprint for OEMs

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626