Description

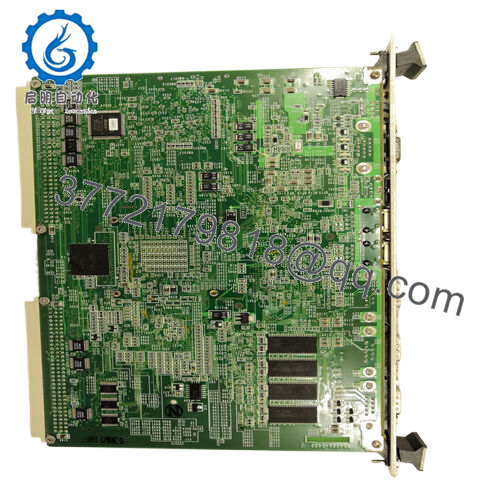

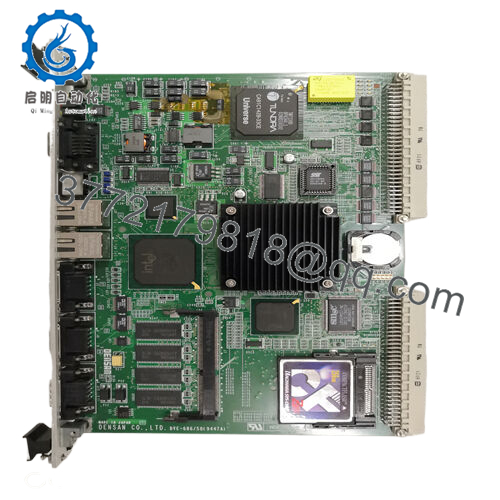

The DVE-68650 is a cutting-edge industrial vision processor designed to handle the most demanding image analysis tasks in automated inspection systems. It acts as the brain of machine vision setups, processing data from multiple high-speed cameras to perform complex calculations—such as pattern matching, OCR (optical character recognition), and 3D measurement—with sub-millisecond latency.

DVE-68650

This processor is part of a comprehensive vision ecosystem, integrating seamlessly with cameras, lighting systems, and PLCs to form closed-loop inspection systems. In the architecture of a vision system, it sits between the image sensors and the control system, converting raw pixel data into actionable insights that trigger immediate responses (e.g., rejecting defective parts, adjusting production parameters). What makes theDVE-68650 invaluable to quality engineers and system integrators is its ability to maintain accuracy even at production speeds exceeding 1,000 parts per minute, ensuring no defective items slip through the cracks.

DVE-68650

Main features and advantages:

DVE-68650

Technical specifications:

Model DVE-68650

Type Industrial Machine Vision Processor

Power Supply 24V DC (18-30V range), redundant inputs

Operating Temperature -10°C to +60°C (14°F to +140°F)

Mounting DIN rail (35mm standard) / Panel mount

Dimensions 220mm x 160mm x 80mm (W x H x D)

Weight 2.8kg (6.17lb)

Interfaces 8 x GigE Vision, 4 x USB3 Vision, 2 x CoaXPress, EtherCAT, PROFINET

Certifications IEC 61131-2, UL 508, CE, FDA 21 CFR Part 11

Processing Capacity 16 x 4K streams @ 60fps

AI Acceleration Dedicated neural network engine (8 TOPS)

Memory 32GB DDR4 (ECC protected)

Storage 256GB industrial SSD

Environmental Rating IP40

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

DVE-68650

Application areas:

In the intricate landscape of industrial vision systems, where accurate inspection and quality control are paramount, the DVE-68650 emerges as a transformative solution. Imagine a high-speed pharmaceutical packaging line, where every pill bottle must be inspected for proper labeling, seal integrity, and fill level. A single missed defect could lead to regulatory violations or compromised patient safety. Similarly, in a solar panel manufacturing facility, detecting micro-cracks in silicon wafers during production is critical to ensuring long-term panel efficiency—overlooking even a tiny flaw can reduce energy output by 10% or more. This is where the DVE-68650 excels. Used in industrial automation across sectors like pharmaceuticals, electronics, and renewable energy, it serves as an advanced machine vision processor, analyzing high-resolution images in real time to identify defects, verify measurements, and ensure compliance with strict quality standards.

Related products:

ABB 216VC62a/P1000 HESG324442R112

TruPlasma Bipolar 4010

EATON XV-460-57TQB-1-50

Bailey DSSB-01C

EMERSON SLS1508

EMERSON KJ2201X1-JA1

HIMA 80105 984080105

BENTLY 3500/91M 190782-01

GE IS400AEBMH1AJD

ProSoft PLX32-EIP-PND

2214-30SLQTA

Stahl 9470/22-16-11

A-B 22A-A2P3N114

A-B 22A-A2P3N114

HONEYWELL 05701-A-0302

HONEYWELL 05701-A-0302

HONEYWELL 05701-A-0302

HONEYWELL 05701-A-0302

HONEYWELL 05701-A-0302

Woodward 2301A 9907-018

Siemens 6GK5202-2BB00-2BA3

GE DS200TCQCG1AJD

WOODWARD 2301D 8273-126

GE 239-RTD-AN

GE 239-RTD-AN

Emerson FX-316 960132-01

GE 239-RTD-AN

BENTLY 24765-01-01

251-046

GE 269PLUS-100P-120VAC

Basler BE3-25A

Stahl 9460/12-08-11

TRICONEX PLM3900N

GE IS420UCSBH1A

BENTLY 1900/65A-00-00-01-00-01 screen

Valmet D202593

GE Physical 239 239-RTD-AN

TRICONEX 8310

Valmet A413000

GE VMIVME2540-300

A-B 2711P-B10C15D1

A-B 2711P-T12W22D9P-BSHK

B&R 2AO300.6

B&R 2AO300.6

GE 8507-BI-DP 8507-BI-DP-01

Honeywell FC-SCNT01

Prosoft RLX2-IFH24E

GE VMIVME2540

TeIKOOR PSMU-350-3 CPCIAC-6U-500 900-7002-10

Emerson 1C31222G01

Emerson 1C31219G01

PEPPERL+FUCHS HiD2082

Rockwell TC-302-02-4M0

Rockwell TC-303-02-4M0

Emerson SS4310T01

ABB 2CSG299893R4052

GE SLN042 IC086SLN042-A

GE SLN080 IC086SLN080-A

GE VMIACC-5595-208 350-805595-208N

GE SBC486DX66

BENTLY 3500/22M 288055-01 new large truck model

BENTLY 3500/22M 146031-01 small card

BENTLY 3500/22M 123M4610 new cable

GE F650 F650BFBF2G0HIE

Triconex IMFF4703x

GE VMIACC-5595-208

GE IS215WEPAH2B

GE IS210AEAAH2B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626