Description

| Model | DSTXW110 |

| Brand | ABB |

| Type | Wireless Industrial Timing Synchronization Module |

| Internal Oscillator | Temperature-compensated quartz oscillator, ±5 ppm over -20°C to +70°C |

| Supported Timing Protocols | IEEE 1588 PTP (wireless profile), NTPv4, SNTP, PPS input/output |

| Wireless Interfaces | Dual-band Wi-Fi (2.4GHz/5GHz, 802.11 a/b/g/n/ac) |

| Optional Wireless | LTE-M/NB-IoT cellular connectivity |

| Synchronization Outputs | 4 x programmable pulse outputs (1PPS, 1PPM, custom intervals) |

| Synchronization Inputs | 2 x pulse inputs (PPS, wired reference) |

| Wired Network | 1 x 10/100/1000 Mbps Ethernet port (optional wired backup) |

| Timekeeping Resolution | 100 microseconds |

| Wireless Sync Accuracy | <10 milliseconds (Wi-Fi), <50 milliseconds (cellular) |

| Processing Power | 32-bit microcontroller with wireless timing coprocessor |

| Memory | 1MB RAM, 16MB flash storage |

| Power Supply | 24V DC ±15% or optional 3.6V lithium battery (with 5-year life) |

| Power Consumption | <8W (wired power), <100mW (battery mode, periodic sync) |

| Operating Temperature Range | -30°C to +75°C (-22°F to +167°F) |

| Enclosure Rating | IP65 (outdoor), NEMA 4X |

| Mounting Type | DIN rail, pole mount, or wall mount |

| Dimensions | 90mm x 120mm x 50mm (W x H x D) |

| Protection | Enhanced EMC immunity, 8kV surge protection, reverse polarity protection |

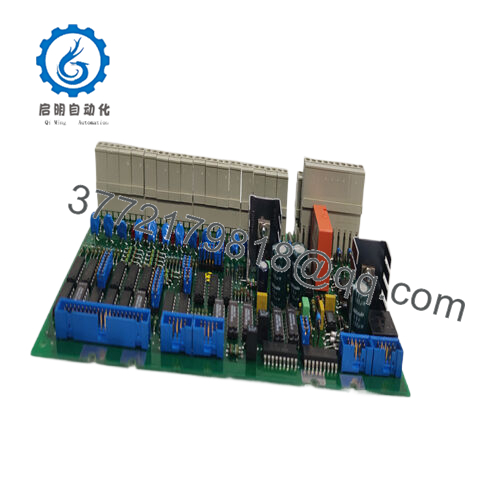

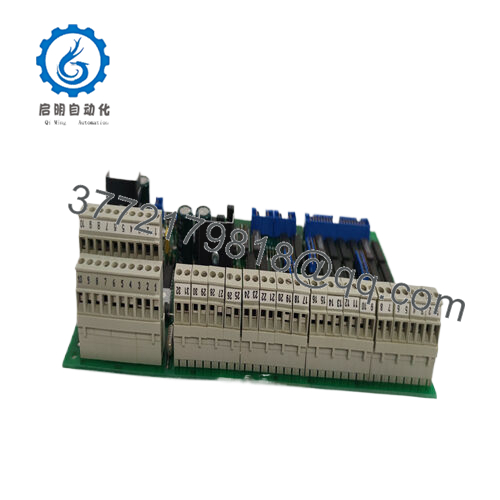

DSTXW110

The DSTXW110 is an advanced wireless industrial timing synchronization module designed to provide precision timekeeping and synchronization capabilities in environments where traditional wired connections are challenging or cost-prohibitive. As a specialized solution in the timing product lineup, it combines reliable wireless communication technologies with accurate timing functionality, enabling seamless synchronization across distributed industrial systems without physical cabling.

DSTXW110

This module is engineered to integrate with diverse industrial control architectures, including remote sensor networks, mobile equipment systems, and geographically dispersed infrastructure. Its design prioritizes robust wireless connectivity, power efficiency, and industrial-grade durability, making it suitable for both indoor and outdoor applications in harsh environments. For plant engineers and system integrators working with distributed systems, the DSTXW110 offers significant value through its flexible deployment options, reduced installation costs, and reliable synchronization performance, eliminating the limitations of wired timing solutions in complex industrial settings.

DSTXW110

The DSTXW110 delivers precise wireless timing performance with its high-stability temperature-compensated quartz oscillator (±5 ppm accuracy over -20°C to +70°C), ensuring consistent synchronization across wireless networks. This level of accuracy meets the needs of most industrial applications requiring coordinated operation between distributed devices, with a timekeeping resolution of 100 microseconds that supports precise event logging and control sequencing. The module supports a hybrid synchronization approach, combining wireless timing protocols with optional wired inputs, enabling it to operate as a standalone wireless master or integrate with existing wired timing infrastructure like the DSTS106.

Wireless connectivity is the defining feature of the DSTXW110, featuring dual-band industrial-grade Wi-Fi (2.4GHz and 5GHz) with support for IEEE 802.11 a/b/g/n/ac standards, ensuring reliable communication in congested industrial RF environments. It also includes optional cellular connectivity (LTE-M/NB-IoT) for applications requiring synchronization across extremely large areas or remote locations beyond Wi-Fi range. The module implements advanced wireless timing mechanisms that minimize latency and jitter, including timestamped wireless packets and adaptive synchronization intervals that adjust based on connection quality.

Hardware highlights include a rugged, weather-resistant design with an IP65 rating for outdoor installations and an extended operating temperature range of -30°C to +75°C, ensuring reliable operation in extreme industrial environments. The DSTXW110 features enhanced electromagnetic compatibility (EMC) protection and robust wireless security protocols (WPA3-Enterprise, VPN support) to prevent unauthorized access and ensure data integrity. It includes comprehensive diagnostic capabilities with real-time wireless signal monitoring, synchronization status indicators, and fault logging, enabling proactive troubleshooting of connectivity issues. The module offers flexible power options, including 24V DC wired power or optional battery operation with low-power modes for remote, untethered installations.

DSTXW110

In industrial environments where wired connections are impractical or costly to install, maintaining reliable timing synchronization presents unique challenges. From remote monitoring stations spread across large facilities to mobile equipment in manufacturing plants and outdoor infrastructure like solar farms, these applications require a timing solution that delivers precision without the constraints of physical cabling. This is where the DSTXW110 excels, introducing wireless timing synchronization capabilities to bridge connectivity gaps in industrial automation systems.

The DSTXW110 is ideally suited for large-scale outdoor facilities such as solar power plants, where it synchronizes distributed inverters, weather monitoring sensors, and performance tracking systems across expansive areas without expensive trenched cabling. In dynamic manufacturing environments with mobile equipment like automated guided vehicles (AGVs), it provides continuous timing synchronization as assets move throughout the facility. Remote water treatment facilities and pipeline monitoring stations leverage it to maintain time alignment between dispersed sensors, pumps, and control systems, ensuring consistent data collection and coordinated operation. By addressing the unique challenges of wireless timing—such as signal reliability, latency management, and power efficiency—the DSTXW110 delivers flexible, reliable synchronization for industrial systems where wired connections are impractical.

DSTXW110

Related products:

DSTS106 – Enhanced timing module that can serve as a wired master clock for the DSTXW110 in hybrid wired/wireless systems.

DSDX451 – Communication gateway that integrates wireless timing data from the DSTXW110 into enterprise networks.

DSPS24-4 – Power supply unit optimized for powering the DSTXW110 in wired installations.

DSBAT100 – High-capacity lithium battery pack for extended untethered operation of the DSTXW110.

DSANT100 – High-gain industrial antenna for extending the wireless range of the DSTXW110.

DSHMI200 – Enhanced HMI panel that displays wireless synchronization status from the DSTXW110.

DSLOG200 – Data logger that uses precise time stamps from the DSTXW110 for event recording in remote locations.

DSTXW110

Installation and maintenance:

Before installing the DSTXW110, perform a site survey to identify optimal placement for wireless signal strength, avoiding physical obstructions and sources of RF interference. For outdoor installations, ensure the module is mounted in a location protected from direct sunlight when possible, or use a sun shield to prevent overheating in extreme temperatures.

When deploying the DSTXW110, position the antenna(s) for maximum line-of-sight to other wireless nodes or the master clock where possible. For battery-powered installations, configure synchronization intervals based on application requirements to balance accuracy and power consumption. In hybrid systems, connect the optional wired Ethernet port to the primary timing source for fallback synchronization if wireless connectivity is temporarily lost. Secure the wireless network with enterprise-grade security protocols and configure VPN tunnels for synchronization across public networks.

For maintenance of the DSTXW110, utilize the module’s remote monitoring capabilities to perform weekly checks of wireless signal strength, synchronization status, and battery level (if applicable). Conduct quarterly physical inspections of outdoor installations to ensure mounting hardware remains secure and enclosures are free from debris or water intrusion. Verify timing accuracy semi-annually using a reference clock or the DSTEST200 tool, adjusting synchronization parameters if environmental changes affect wireless performance.

Firmware updates can be applied remotely over the wireless connection or via wired Ethernet during scheduled maintenance windows. For battery-powered units, ensure sufficient battery capacity before initiating updates. Maintain records of signal strength trends, synchronization performance, and maintenance activities to optimize wireless network performance over time.

Other ABB product models:

ABB FI830F

ABB FI840F

ABB FPR3203526R1002A

ABB FPR3600227R1202-J 07KR31

ABB FS300R12KE3/AGDR-72C

ABB FS450R12KE3/AGDR-71C

ABB FSA80

ABB G2000A5.7ST

ABB GCC960C102 3BHE033067R0102

ABB GDB021BE HIEE410455P104

ABB GDB021BE01 HIEE300766R0001

ABB GDC801B 3BHE051592R0101

ABB GDC801B102 3BHE051592R0102

ABB GFD233A 3BHE022294R0101

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GJR5252300R0101 07AC91

ABB GJR5252300R3101 07AC91

ABB GJR5252300R3101 07AC91

ABB GJR5253100R0270 07KT98

ABB GLBS200516R

ABB GMKP2800-32IBY

ABB GNT0104500R0002

ABB GRBTU 3BSE013175R1

ABB GVC750BE101 3BHE009681R0101 GVC750BE101 3BHE013088R001 5SHY3545L0010

ABB HAI805

ABB HBFFAEAGNBA1BAA11G

ABB HBS01-EPD

ABB HBS01-EPD

ABB HC800

ABB HESG112548R12

ABB HESG324430R11/B 216GD61A

ABB HESG324442R0112

ABB HESG447419R0001 70EA05a-E

ABB HIEE205011R0002(UNS3670A)

ABB HIEE205014R0001 UNC4673A, V1

ABB HIEE205014R1 HI220856-312/20 UNC4673AV1

ABB HIEE300698R0001(KUC321AE)

ABB HIEE300888R0002 UAC389AE02

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626