Description

| Model | DSTS105 |

| Brand | ABB |

| Type | Compact Industrial Timing Synchronization Module |

| Internal Oscillator | High-stability quartz oscillator, ±10 ppm over -10°C to +60°C |

| Supported Timing Protocols | NTPv4, SNTP, PPS input/output |

| Synchronization Outputs | 4 x programmable pulse outputs (1PPS, 1PPM, configurable) |

| Synchronization Inputs | 2 x pulse inputs (PPS, external trigger) |

| Network Interfaces | 1 x 10/100 Mbps Ethernet port |

| Timekeeping Resolution | 1 millisecond |

| Time Update Interval | Configurable (1-3600 seconds) |

| Processing Power | Low-power 32-bit microcontroller |

| Memory | 256KB RAM, 2MB flash storage |

| Power Supply | 24V DC ±15% (single input) |

| Power Consumption | <5W |

| Operating Temperature Range | -10°C to +60°C (14°F to +140°F) |

| Mounting Type | DIN rail (35mm) or direct panel mount |

| Dimensions | 20mm x 80mm x 100mm (W x H x D) |

| Protection | Basic EMC immunity, 4kV surge protection, reverse polarity protection |

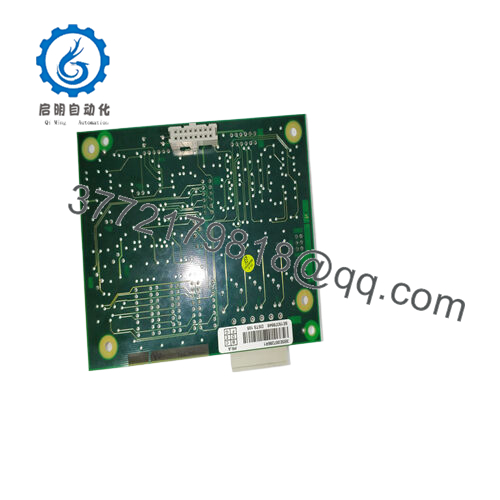

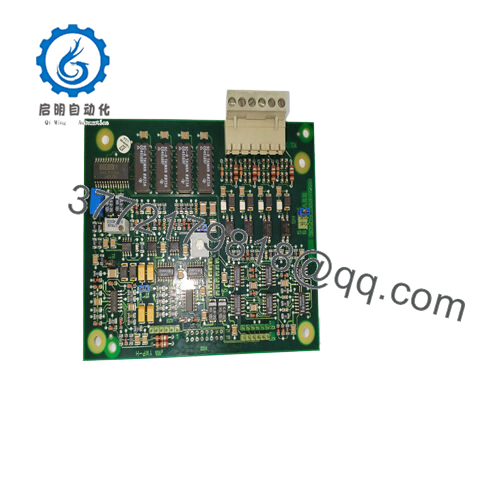

DSTS105

The DSTS105 is a compact industrial timing synchronization module designed to provide reliable timekeeping and basic synchronization capabilities for small-scale automation systems. As an entry-level solution in the timing product lineup, it focuses on delivering core timing functions in an ultra-compact form factor, making it easy to integrate into limited cabinet space and simple automation architectures.

DSTS105

This module is engineered to work seamlessly with basic industrial control systems, including small PLCs, standalone controllers, and simple sensor networks. Its design prioritizes ease of installation, low maintenance requirements, and essential timing features, making it suitable for applications where advanced synchronization protocols and high precision are not required. For plant technicians and small system integrators, the DSTS105 offers significant value through its straightforward operation, affordable price point, and reliable performance, ensuring basic timing synchronization for small industrial systems.

Main features and advantages:

The DSTS105 delivers reliable basic timing performance with its high-stability quartz oscillator (±10 ppm accuracy over -10°C to +60°C), providing consistent timekeeping for small-scale industrial applications. This level of accuracy ensures sufficient synchronization for coordinating basic equipment and simple control loops, with a timekeeping resolution of 1 millisecond that meets the needs of standard small-system automation tasks. The module supports essential timing protocols including NTPv4 and SNTP, enabling basic time synchronization with other devices in the system via Ethernet.

Synchronization functionality in the DSTS105 is focused on essential needs, featuring 4 programmable pulse outputs and 2 pulse inputs that can be used to synchronize external devices or receive timing signals from a master clock. This configuration provides enough flexibility for small systems without the complexity of larger timing modules. The module includes basic timing functions such as interval triggering, time-of-day scheduling, and simple event logging, allowing for the implementation of standard synchronization logic in small automation setups.

Hardware highlights include an ultra-compact, rugged design with an operating temperature range of -10°C to +60°C, ensuring reliable operation in typical small industrial environments. The DSTS105 features basic electromagnetic compatibility (EMC) protection suitable for small-scale industrial settings, making it resistant to common electrical noise from nearby equipment. It also includes essential diagnostic capabilities, with status LEDs for power, synchronization lock, and network connectivity, enabling quick visual checks and basic troubleshooting. The module’s tiny footprint makes it easy to install in crowded control cabinets or even directly on machine mounts in space-constrained locations.

Application areas:

In the realm of small-scale industrial automation, reliable timing synchronization is often overlooked but remains crucial for ensuring smooth operation of interconnected devices. From small manufacturing workshops with a handful of machines to local utility stations managing basic pumping systems, these applications require a timing solution that is both cost-effective and easy to implement without sacrificing essential functionality. This is where the DSTS105 excels, providing a compact and reliable timing synchronization module specifically designed for small industrial systems that need consistent timekeeping without the complexity of larger solutions.

The DSTS105 is ideally suited for small manufacturing cells, where it synchronizes production equipment like labelers, fillers, and basic assembly machines to ensure coordinated operation and consistent product quality. In local wastewater lift stations, it coordinates pump cycles, level sensors, and alarm systems, ensuring efficient operation and timely response to changing conditions. Small-scale food processing facilities leverage it to synchronize mixing equipment, conveyor belts, and packaging machines, maintaining production schedules and quality standards. By addressing the specific timing needs of small industrial systems—such as simple setup, space-saving design, and reliable basic synchronization—the DSTS105 delivers essential timing functionality without unnecessary complexity or cost.

Related products:

DSTD108 – Compact timing and control module that can utilize synchronization signals from the DSTS105 in small automation systems.

DSDX451 – Communication gateway that can extend the DSTS105’s synchronization capabilities to larger networks if needed.

DSPS24-2 – Ultra-compact power supply unit optimized to provide reliable power to the DSTS105 in space-constrained installations.

DSHMI100 – Basic HMI panel that can display time and synchronization status from the DSTS105.

DSLOG100 – Entry-level data logger that can use time stamps from the DSTS105 for basic event recording.

DSTEST100 – Simple calibration tool for verifying the timing accuracy of the DSTS105 during maintenance.

Installation and maintenance:

Before installing the DSTS105, ensure the mounting location provides adequate ventilation with at least 15mm of clearance above and below the module—though its low power consumption means heat buildup is minimal. Its ultra-compact design allows for installation in the smallest control cabinets or even directly on machine frames using optional mounting brackets.

When wiring the DSTS105, use standard industrial cables for all connections, with shielded cables recommended for pulse synchronization signals to minimize interference in small electrical enclosures. Connect the power supply to a stable 24V DC source, preferably from the same power distribution as the connected control devices to avoid ground loops. For network connections, use Cat5e or higher Ethernet cables for reliable NTP communication. Configure basic parameters such as IP address and synchronization interval using the simplified web interface or manufacturer’s configuration software, which is designed for quick setup without specialized training.

For maintenance of the DSTS105, perform monthly checks of status LEDs to verify power, network connectivity, and synchronization lock. Conduct quarterly visual inspections to ensure connections remain tight and free from corrosion, especially in dusty or humid environments. Verify timing accuracy annually using a simple reference clock or the DSTEST100 tool to ensure continued performance.

Firmware updates can be applied during scheduled maintenance periods using the manufacturer’s software tools via the network interface. Before updating, note current configuration settings as a backup. Maintain simple records of maintenance activities and any configuration changes to support troubleshooting.

Other ABB product models:

ABB FI830F

ABB FI840F

ABB FPR3203526R1002A

ABB FPR3600227R1202-J 07KR31

ABB FS300R12KE3/AGDR-72C

ABB FS450R12KE3/AGDR-71C

ABB FSA80

ABB G2000A5.7ST

ABB GCC960C102 3BHE033067R0102

ABB GDB021BE HIEE410455P104

ABB GDB021BE01 HIEE300766R0001

ABB GDC801B 3BHE051592R0101

ABB GDC801B102 3BHE051592R0102

ABB GFD233A 3BHE022294R0101

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GJR5252300R0101 07AC91

ABB GJR5252300R3101 07AC91

ABB GJR5252300R3101 07AC91

ABB GJR5253100R0270 07KT98

ABB GLBS200516R

ABB GMKP2800-32IBY

ABB GNT0104500R0002

ABB GRBTU 3BSE013175R1

ABB GVC750BE101 3BHE009681R0101 GVC750BE101 3BHE013088R001 5SHY3545L0010

ABB HAI805

ABB HBFFAEAGNBA1BAA11G

ABB HBS01-EPD

ABB HBS01-EPD

ABB HC800

ABB HESG112548R12

ABB HESG324430R11/B 216GD61A

ABB HESG324442R0112

ABB HESG447419R0001 70EA05a-E

ABB HIEE205011R0002(UNS3670A)

ABB HIEE205014R0001 UNC4673A, V1

ABB HIEE205014R1 HI220856-312/20 UNC4673AV1

ABB HIEE300698R0001(KUC321AE)

ABB HIEE300888R0002 UAC389AE02

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626