Description

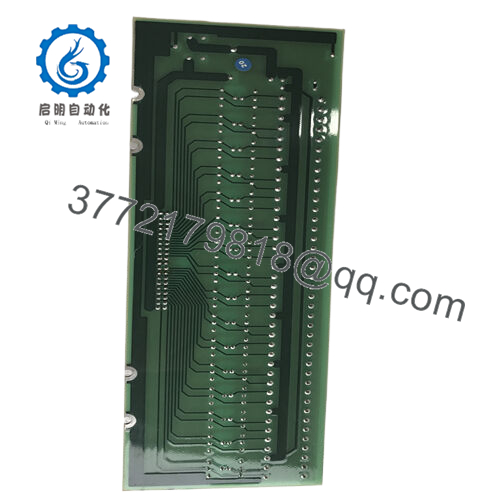

| Model | DSTA180 |

| Brand | ABB |

| Type | Ultra-Precision Industrial Timing & Synchronization Module |

| Internal Oscillator | Rubidium atomic oscillator, ±0.01 ppm over -40°C to +85°C |

| Supported Protocols | IEEE 1588 PTP (v2.1), NTPv4, SNTP, IRIG-B (AC/DC), PPS, 10MHz |

| Synchronization Inputs | 3 x GNSS receivers (GPS/GLONASS/BeiDou), 2 x IRIG-B, 2 x 1PPS inputs |

| Timing Outputs | 8 x programmable pulse outputs, 4 x frequency references (1PPS, 10MHz, 1MHz, 100kHz) |

| Network Interfaces | 6 x 10/100/1000/10000 Mbps Ethernet ports (PTP-aware with hardware timestamping) |

| Timekeeping Resolution | 1 nanosecond |

| Holdover Performance | <500ns drift per hour without external references |

| Power Supply | 24V DC ±15% (triple redundant inputs with automatic failover) |

| Power Consumption | <15W |

| Operating Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Mounting Type | DIN rail (35mm) with vibration-resistant locking clips |

| Dimensions | 45mm x 140mm x 170mm (W x H x D) |

| Protection | Enhanced EMC immunity, 10kV surge protection, reverse polarity protection |

DSTA180

The DSTA180 is a state-of-the-art industrial timing and synchronization module designed to serve as the cornerstone of precision timekeeping in large-scale, distributed automation systems. As the next evolution in industrial timing technology, it builds on the strengths of previous models while introducing breakthrough capabilities to support the most complex Industry 4.0 ecosystems. This module specializes in generating ultra-stable timing signals, synchronizing thousands of networked devices across expansive areas, and maintaining consistent time references even in the face of network disruptions or reference source failures.

DSTA180

Engineered to integrate seamlessly with modern industrial networks—including Ethernet/IP, PROFINET, and 5G-enabled systems—the DSTA180 supports the latest timing protocols and communication standards, ensuring compatibility with PLCs, DCS controllers, edge computing devices, and cloud platforms. Its design prioritizes nanosecond-level precision, multi-layered redundancy, and intelligent self-healing capabilities, making it suitable for mission-critical applications where timing errors can lead to costly downtime, quality issues, or safety risks. For system architects and network engineers, the DSTA180 offers unparalleled value through its expanded connectivity, adaptive synchronization algorithms, and comprehensive monitoring features, simplifying the deployment of large-scale timing infrastructures.

DSTA180

Main features and advantages:

The DSTA180 redefines industrial timing precision with its advanced atomic clock technology, featuring a rubidium oscillator that maintains accuracy within ±0.01 ppm (parts per million) over its entire operating temperature range—ten times more precise than its predecessor. This exceptional stability ensures that even across multi-site industrial campuses spanning kilometers, clock drift remains negligible, preventing the cumulative timing errors that can degrade system performance. The module supports the latest timing protocols including IEEE 1588 PTP (v2.1) with hardware-accelerated timestamping, enabling sub-10-nanosecond synchronization across Ethernet networks.

Connectivity is a defining strength of the DSTA180, offering a comprehensive suite of input/output options including 8 programmable timing outputs, triple redundant GNSS (GPS/GLONASS/BeiDou) receivers, and support for both wired (IRIG-B, 1PPS, 10MHz) and wireless (LTE-M/NB-IoT) synchronization sources. This versatility allows it to function as a primary grandmaster clock or integrate into existing timing architectures, providing seamless redundancy for mission-critical applications. The module incorporates adaptive time-aware networking capabilities, automatically prioritizing timing traffic and adjusting synchronization parameters based on network conditions to maintain precision even in congested or unstable environments.

Hardware highlights include a ruggedized design with an extended operating temperature range of -40°C to +85°C, ensuring reliable performance in extreme industrial conditions—from frozen outdoor installations to high-temperature manufacturing facilities. The DSTA180 features enhanced electromagnetic compatibility (EMC) protection and 10kV surge immunity, making it resistant to electrical noise and transient events in high-power industrial settings. It also includes advanced security features such as hardware root of trust, encrypted time distribution, and real-time intrusion detection, protecting critical timing infrastructure from evolving cyber threats. Intelligent diagnostic functions provide continuous monitoring of synchronization health, oscillator stability, and network performance, with predictive analytics that alert operators to potential issues before they affect system timing.

DSTA180

Application areas:

In the rapidly evolving landscape of industrial automation, where distributed systems span larger geographic areas and process data at unprecedented speeds, the demand for ultra-precise timing solutions has reached new heights. From smart factories with interconnected machinery to cross-regional energy grids and large-scale transportation systems, the need to synchronize operations with nanosecond-level accuracy is critical for optimizing efficiency, ensuring safety, and enabling advanced analytics. This is where the DSTA180 emerges as a cutting-edge solution, building on the legacy of previous timing modules to deliver the most advanced synchronization capabilities for the most demanding industrial environments.

The DSTA180 is ideally suited for large-scale semiconductor fabs, where it synchronizes hundreds of precision tools across cleanroom environments to ensure nanoscale manufacturing accuracy. In cross-border energy transmission networks, it coordinates phasor measurement units (PMUs) and grid controllers across vast distances, enabling real-time stability monitoring and rapid fault response. Major transportation hubs, such as automated container ports, rely on it to synchronize crane operations, conveyor systems, and inventory tracking, optimizing logistics flow and reducing operational bottlenecks. By addressing challenges like long-distance timing propagation, multi-network synchronization, and enhanced resilience against cyber threats, the DSTA180 sets a new standard for industrial timing in the era of globalized, interconnected automation.

Related products:

DSDX452 – Advanced 10-gigabit communication gateway that works with the DSTA180 to distribute PTP-synchronized timing across enterprise-wide industrial networks.

DSPC170 – Process control module that leverages nanosecond timing signals from the DSTA180 for ultra-precise multi-loop process control.

DSLOG300 – High-speed data logger that integrates with the DSTA180 to capture time-stamped process data with picosecond-level precision.

DSPS24-12 – Triple-redundant power supply unit optimized to provide uninterrupted power to the DSTA180 in critical applications.

DSHMI300 – Advanced HMI panel that displays real-time synchronization status, timing metrics, and predictive alerts from the DSTA180.

DSCOMM500 – 5G/6G-ready communication module that extends the DSTA180’s synchronization capabilities to remote field devices.

DSTEST300 – Precision calibration system specifically designed to verify the sub-10-nanosecond accuracy of the DSTA180.

DSALM300 – AI-powered alarm management system that analyzes time-stamped alerts from the DSTA180 for proactive fault resolution.

Installation and maintenance:

Before installing the DSTA180, ensure the mounting location provides an unobstructed view of the sky for GNSS reception, with antenna placement optimized to minimize multipath interference. For multi-module installations, position units to enable cross-synchronization and maintain at least 40mm of clearance above and below each module to ensure proper heat dissipation, critical for oscillator stability.

When wiring the DSTA180, use shielded, twisted-pair cables with low capacitance for all synchronization inputs and outputs, with cable shields grounded at both ends using dedicated grounding lugs. Connect all three redundant power inputs to separate, isolated 24V DC supplies to ensure continuous operation during power interruptions. For network connections, use Cat7 or higher Ethernet cables to support 10-gigabit speeds and PTP’s nanosecond-level timing requirements. During configuration, establish a multi-tiered synchronization hierarchy with primary (GNSS), secondary (network PTP), and tertiary (internal rubidium oscillator) references, with automatic failover parameters set based on application criticality.

For maintenance of the DSTA180, utilize the module’s built-in diagnostic tools to perform daily checks of synchronization status, including offset measurements, jitter analysis, and reference source availability. Conduct monthly inspections of antenna connections, cabling, and grounding to ensure they remain secure and free from environmental damage. Schedule annual calibration using traceable national metrology institute standards to maintain the ±0.01 ppm accuracy specification, with calibration data stored for compliance documentation.

Firmware updates should be applied during planned maintenance windows, leveraging the module’s dual-image capability to enable fail-safe updates without timing interruptions. Before updating, back up all configuration settings and verify compatibility with connected devices. Maintain detailed records of synchronization performance metrics, including long-term drift analysis and holdover performance, to establish a baseline for predictive maintenance and performance trending.

Other ABB product models:

ABB FI830F

ABB FI840F

ABB FPR3203526R1002A

ABB FPR3600227R1202-J 07KR31

ABB FS300R12KE3/AGDR-72C

ABB FS450R12KE3/AGDR-71C

ABB FSA80

ABB G2000A5.7ST

ABB GCC960C102 3BHE033067R0102

ABB GDB021BE HIEE410455P104

ABB GDB021BE01 HIEE300766R0001

ABB GDC801B 3BHE051592R0101

ABB GDC801B102 3BHE051592R0102

ABB GFD233A 3BHE022294R0101

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GJR5252300R0101 07AC91

ABB GJR5252300R3101 07AC91

ABB GJR5252300R3101 07AC91

ABB GJR5253100R0270 07KT98

ABB GLBS200516R

ABB GMKP2800-32IBY

ABB GNT0104500R0002

ABB GRBTU 3BSE013175R1

ABB GVC750BE101 3BHE009681R0101 GVC750BE101 3BHE013088R001 5SHY3545L0010

ABB HAI805

ABB HBFFAEAGNBA1BAA11G

ABB HBS01-EPD

ABB HBS01-EPD

ABB HC800

ABB HESG112548R12

ABB HESG324430R11/B 216GD61A

ABB HESG324442R0112

ABB HESG447419R0001 70EA05a-E

ABB HIEE205011R0002(UNS3670A)

ABB HIEE205014R0001 UNC4673A, V1

ABB HIEE205014R1 HI220856-312/20 UNC4673AV1

ABB HIEE300698R0001(KUC321AE)

ABB HIEE300888R0002 UAC389AE02

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626