Description

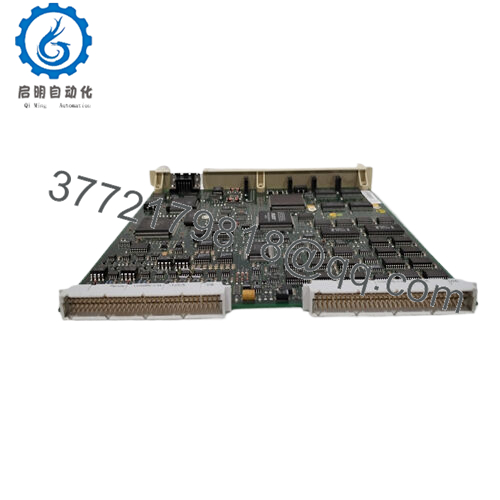

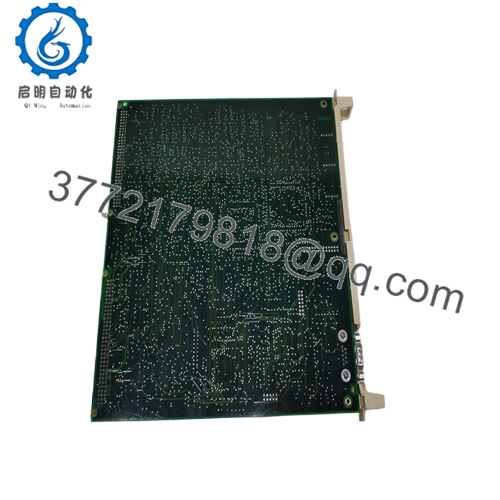

Product Model: DSQC322

- Product Brand: ABB

- Product Series: DSQC (Distributed Systems & Components / I/O-module family)

- Product Features:

• High-performance I/O/control module designed for industrial automation and distributed control systems.

• Suitable as a spare or retrofit module in legacy ABB/robotics/automation racks (part-number often referenced as 3HAB5960-1).• Industrial-grade build, supports demanding environments and enables continued use of older automation installations.

- DSQC322

Applications & Industry Context

In many manufacturing plants and process-automation facilities, there remain racks of legacy control modules from major vendors such as ABB. Whether in robotics cells, discrete machine lines, or older DCS/PLC systems, these modules continue to play critical roles in signal acquisition, control logic, I/O, and communication. The DSQC322 module is one such component designed to fit into these installations.

Consider a scenario: a large automotive assembly line uses ABB robots and a distributed control rack for I/O and logic. A field fault occurs where one control board fails. Replacing an entire rack or rewiring can cost days of downtime. Instead, a direct drop-in spare module like the DSQC322 allows the maintenance team to swap, reboot, and resume production quickly—retaining existing harnesses, logic, and wiring.

Another example: in a chemical plant that installed ABB’s distributed system decades ago, engineers face that spare part availability is dwindling. Modules like the DSQC322 become strategic spares—if the original fails without a replacement, you face costly redesign. By maintaining a tested unit in inventory, you reduce risk and future proof the line for a while longer.

The key challenge in such contexts is: legacy systems often remain critical, but the parts may no longer be in current production. Sourcing a module that matches the original slot, firmware, back-plane interface and mechanical footprint is essential for restoration. The DSQC322 addresses exactly that niche: it builds on ABB’s DSQC family, enabling you to preserve the system’s architecture without forced migration immediately.

Product Role & System Fit

So, where exactly does the DSQC322 sit in a system? This module is not a stand-alone PLC CPU; rather, it is a module intended to be installed in a rack/backplane system (or integrated into an automation cabinet) and serve as part of the I/O, control or interface array.

In simple terms: you have your system rack (power supply + backplane + modules). The DSQC322 occupies one rack slot, connects via the backplane or via external I/O connectors, receives wiring from sensors/actuators (or interfaces with robotics/controllers), and communicates with the central logic via bus or backplane signals. Because this is a module designed for older ABB/distributed I/O architectures, its compatibility with the rack’s slot, connectors, and firmware is vital.

For integrators: you must verify the DSQC322’s slot number, module revision, firmware (if applicable), and the original wiring harness mapping. Swapping in a different board revision or variant can lead to mis-mapped I/O or faults. The DSQC322 is therefore a component that fits within a legacy assembly, letting you preserve your wiring, logic and system configuration with minimal intervention.

Because automation systems often extend over years or decades, modules like the DSQC322 allow you to maintain continuity and defer a full system migration. While migrating everything to a new platform is often desirable long-term, many facilities prefer to keep existing systems running until budget or downtime windows permit. The DSQC322 enables that strategy.

Technical Features & Benefits

Here are some of the salient features of the DSQC322 and what they mean in practice:

- Industrial-Grade Construction

Listings mark the DSQC322 as an “industrial computer accessory” from ABB. This signals that the module is built for rugged environments—suitable for control cabinets, manufacturing floors, or robotics cells where temperatures, vibration, or electrical noise may be higher. For you, this means reliable operation in challenging conditions without frequent failures. - Legacy System Compatibility & Spare Availability

The DSQC322 is referenced in multiple surplus/automation-parts listings (e.g., 3HAB5960-1 DSQC322). That means while the module may no longer be manufactured in volume, there is a market for used and refurbished units. For maintenance planning, that means you can source replacements now, test them, and keep them in stock to reduce downtime risk. - Flexibility within Automation Architecture

Some sources describe the DSQC322 as an “I/O module for flexible automation systems.” That suggests the module handles signal I/O (digital/analog) or interface with field devices. For you this means versatility—whether your system handles machine logic, robotics, sensor networks, or distributed I/O nodes, the DSQC322 may fit the bill across many older ABB platforms. - Simplified Maintenance & Integration

Because this is a direct-fit module in the DSQC series, swapping one out involves plug-in mechanics rather than redesigning wiring or logic. This reduces maintenance downtime, simplifies logistics (you don’t need to rewire or reprogram extensively), and lowers cost. - Lifecycle Risk Mitigation

The reality: legacy automation modules eventually become unsupported by manufacturers. By proactively sourcing and stocking a module like DSQC322, you reduce the risk of a future failure causing extended outage while you scramble for replacements. This provides insurance for your automation system.

Technical Specifications Table

| Specification | Value / Description |

|---|---|

| Model | DSQC322 |

| Manufacturer | ABB |

| Function | Automation I/O / Control module for distributed/rack systems |

| Alternate Part-Number | Often referenced as 3HAB5960-1 (DSQC322) |

| Sub-Category | Industrial computer accessory / I/O module |

| Weight | 0.7 lbs (as listed on one source) |

| Typical Application | Automation racks, robotics control, distributed I/O systems |

| Status | Available via surplus/aftermarket; legacy module |

| Warranty (via some sellers) | 1-year warranty offered by some vendors |

Note: Because detailed official datasheet information is limited in public listings, if you’re sourcing a DSQC322 module make sure you verify the version/revision, firmware (if applicable), connector layout, slot compatibility and full mechanical dimensions before installation.

Installation & Maintenance Insights

From a hands-on field perspective, here are some practical tips for installing and maintaining the DSQC322:

- Rack Slot & Backplane Check

Before plugging in the module, ensure the rack slot you’re using matches the original board. Confirm backplane connector alignment, slot number, and keying. A mis-inserted module can cause bus faults or damage. If you’re replacing a failed board, mark the slot and wiring harness before removal. - Wiring Harness Verification

Because the DSQC322 likely takes wiring from sensors, actuators, or I/O nodes, inspect the terminal blocks, harnesses and labels. Ensure that the replacement board matches the original wiring map. Cloning the wiring (or documenting the old board) helps avoid mis-mappings post-install. - Power & Bus Signal Integrity

Check that the supply power to the rack is stable and that the bus/communication signals (if used) are within specification. Poor power or signal integrity can lead to modules going offline or causing system faults—even if the module itself is good. - Spare Board Preparedness

Given the legacy nature of the DSQC322, treat your purchased board as a strategic spare: label it, keep it in clean, dry storage, test it where possible beforehand, and catalog its revision and slot compatibility in your spare-parts register. - Commissioning After Replacement

After swapping in the module, verify that I/O points tied to that slot are responding correctly, check error/fault logs in your control system, and monitor the module for a period (say 24-48 hours) to ensure no intermittent faults due to cabling or bus issues. - Periodic Inspection

Even healthy racks benefit from periodic checks: inspect the module for dust accumulation, connector corrosion, loose terminal screws, and check bus diagnostics. Preventive maintenance reduces the chance of unexpected board failure. - Migration Planning

While replacing a failed board is the immediate fix, consider longer-term migration: plan for phasing out reliance on legacy modules like DSQC322, by mapping logic and wiring so future platform migration becomes smoother.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626