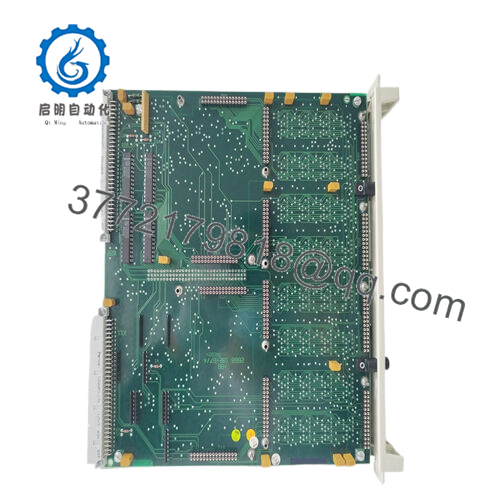

Description

| Model | DSPC170 |

| Brand | ABB |

| Type | Advanced Process Control Module |

| Processor | 32-bit RISC processor, 800 MHz |

| Number of Control Loops | Up to 16 independent loops |

| Supported Control Algorithms | PID, adaptive PID, cascade, feed-forward, ratio control |

| Analog Inputs | 8 channels (16-bit resolution, 4-20mA / 0-10V) |

| Analog Outputs | 8 channels (16-bit resolution, 4-20mA / 0-10V) |

| Digital Inputs | 16 channels (24V DC) |

| Digital Outputs | 16 channels (24V DC, 0.5A per channel) |

| Communication Protocols | Modbus TCP/IP, PROFINET, Ethernet/IP, OPC UA |

| Power Supply | 24V DC ±15% |

| Power Consumption | <15W |

| Operating Temperature Range | -40°C to +70°C (-40°F to +158°F) |

| Mounting Type | DIN rail (35mm) |

| Dimensions | 40mm x 130mm x 160mm (W x H x D) |

| Protection | EMC immunity, overload protection, reverse polarity protection |

DSPC170

The DSPC170 is an advanced process control module designed to serve as the core of precision control systems in industrial automation environments. As a key component in distributed control systems (DCS) and process automation architectures, it specializes in executing complex control algorithms, processing real-time data from sensors, and generating precise control signals for actuators.

DSPC170

This module is engineered to handle a wide range of process control tasks, from simple proportional-integral-derivative (PID) control to advanced model-based control strategies. Its design prioritizes high processing power, flexible I/O integration, and seamless connectivity with other automation components, making it suitable for both simple and complex process control applications. For process engineers and system integrators, the DSPC170 offers significant value through its programmability, advanced diagnostic capabilities, and compatibility with industry-standard protocols, simplifying system design and enabling continuous process optimization.

DSPC170

Main features and advantages:

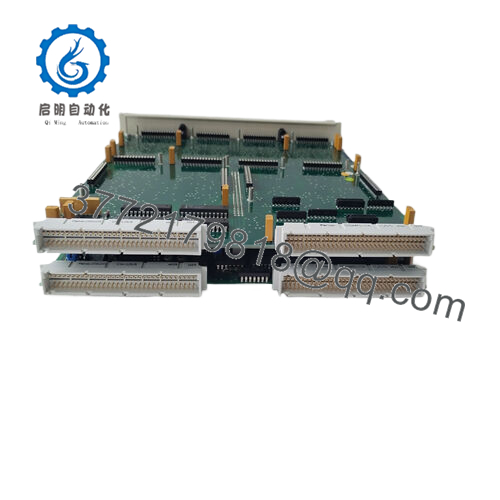

The DSPC170 stands out with its powerful processing capabilities, featuring a high-performance 32-bit RISC processor that executes complex control algorithms with exceptional speed and precision. This processing power enables it to handle up to 16 independent control loops simultaneously, each capable of running advanced control strategies such as adaptive PID, cascade control, and feed-forward control, ensuring optimal performance even in dynamic process environments.

Flexibility is a key strength of the DSPC170, with configurable I/O interfaces that support a wide range of analog and digital signals. It can seamlessly connect to various sensors, including temperature transmitters, pressure transducers, flow meters, and level sensors, as well as actuators such as control valves and variable speed drives. The module incorporates advanced signal conditioning circuitry that ensures accurate measurement of process variables, even in noisy industrial environments, with high-resolution analog-to-digital converters (ADCs) providing 16-bit precision for input signals.

Hardware highlights include a rugged industrial design with an operating temperature range of -40°C to +70°C, ensuring reliable operation in harsh process environments. The DSPC170 features enhanced electromagnetic compatibility (EMC) protection to resist interference from nearby electrical equipment. It also includes comprehensive diagnostic functions, with real-time monitoring of process variables, control loop performance, and hardware status, enabling proactive maintenance and rapid troubleshooting. The module supports seamless integration with communication networks through industry-standard protocols, allowing for easy data exchange with SCADA systems, HMIs, and enterprise-level software for advanced analytics and reporting.

DSPC170

Application areas:

In modern industrial process control, where precision, reliability, and adaptability are paramount, the need for advanced process control modules has grown exponentially. From chemical processing plants requiring tight regulatory control to pharmaceutical facilities demanding precise batch processing, engineers rely on modules that can handle complex control algorithms, integrate seamlessly with diverse sensors and actuators, and provide real-time data for optimization. This is where the DSPC170 emerges as a critical component, designed to deliver advanced process control capabilities for a wide range of industrial applications.

The DSPC170 is ideally suited for use in chemical manufacturing plants, where it controls reaction temperatures, pressure levels, and chemical dosing with exceptional accuracy, ensuring product quality and compliance with safety standards. In food and beverage production, it manages fermentation processes, mixing ratios, and pasteurization temperatures, maintaining consistency across large-scale production runs. Water and wastewater treatment facilities utilize it to regulate pH levels, filtration processes, and chemical dosing, optimizing resource usage and ensuring regulatory compliance. By addressing challenges such as non-linear process dynamics, varying load conditions, and the need for seamless integration with modern communication networks, the DSPC170 provides the robust process control foundation required for efficient and reliable industrial operations.

Related products:

DSDX452 – Advanced communication gateway that enables the DSPC170 to connect with enterprise-level systems and cloud platforms for data analytics.

DSAI160 – Analog input module that expands the DSPC170’s input capacity for applications requiring additional process variable measurements.

DSAO160 – Analog output module that works with the DSPC170 to provide additional control signals for complex process systems.

DSPS24-4 – Redundant power supply unit that ensures reliable power delivery to the DSPC170 and connected components.

DSHMI100 – Human-machine interface panel that integrates with the DSPC170 for local monitoring and control of process parameters.

DSLOG100 – Data logging module that captures and stores process data from the DSPC170 for historical analysis and compliance reporting.

DSTUN100 – Tuning tool specifically designed to optimize the control algorithms of the DSPC170 for specific process applications.

DSALM100 – Alarm management module that works with the DSPC170 to provide advanced alarm handling and notification capabilities.

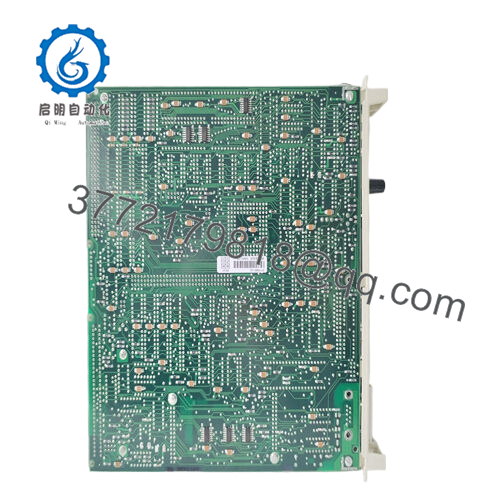

Installation and maintenance:

Before installing the DSPC170, ensure the mounting location provides adequate ventilation with at least 25mm of clearance above and below the module to prevent heat buildup. Verify that the control cabinet environment is free from excessive dust, moisture, and vibration, as these factors can affect the module’s performance and longevity.

When wiring the DSPC170, use shielded twisted-pair cables for all analog signal connections to minimize electromagnetic interference. Separate wiring for power, analog signals, and digital signals to reduce cross-talk and ensure measurement accuracy. Ensure proper grounding of the module and connected devices, with a dedicated ground connection for the control system. Before powering up, verify all wiring connections against the system schematic to prevent damage from incorrect wiring. Configure communication parameters such as IP address and protocol settings to ensure seamless integration with the wider automation network.

For maintenance of the DSPC170, perform monthly checks of process variable trends and control loop performance using the module’s diagnostic tools to identify potential issues before they affect process stability. Conduct quarterly visual inspections to check for loose connections, corrosion, or signs of overheating. Calibrate analog inputs and outputs annually using precision calibration equipment to maintain measurement accuracy.

Schedule firmware updates during planned maintenance periods, ensuring that the latest features and security patches are applied. Before updating, back up the current configuration and control strategies to prevent data loss. Maintain detailed records of maintenance activities, calibration results, and process performance data to support continuous improvement and troubleshooting efforts.

Other ABB product models:

ABB FI830F

ABB FI840F

ABB FPR3203526R1002A

ABB FPR3600227R1202-J 07KR31

ABB FS300R12KE3/AGDR-72C

ABB FS450R12KE3/AGDR-71C

ABB FSA80

ABB G2000A5.7ST

ABB GCC960C102 3BHE033067R0102

ABB GDB021BE HIEE410455P104

ABB GDB021BE01 HIEE300766R0001

ABB GDC801B 3BHE051592R0101

ABB GDC801B102 3BHE051592R0102

ABB GFD233A 3BHE022294R0101

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GJR5252300R0101 07AC91

ABB GJR5252300R3101 07AC91

ABB GJR5252300R3101 07AC91

ABB GJR5253100R0270 07KT98

ABB GLBS200516R

ABB GMKP2800-32IBY

ABB GNT0104500R0002

ABB GRBTU 3BSE013175R1

ABB GVC750BE101 3BHE009681R0101 GVC750BE101 3BHE013088R001 5SHY3545L0010

ABB HAI805

ABB HBFFAEAGNBA1BAA11G

ABB HBS01-EPD

ABB HBS01-EPD

ABB HC800

ABB HESG112548R12

ABB HESG324430R11/B 216GD61A

ABB HESG324442R0112

ABB HESG447419R0001 70EA05a-E

ABB HIEE205011R0002(UNS3670A)

ABB HIEE205014R0001 UNC4673A, V1

ABB HIEE205014R1 HI220856-312/20 UNC4673AV1

ABB HIEE300698R0001(KUC321AE)

ABB HIEE300888R0002 UAC389AE02

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626