Description

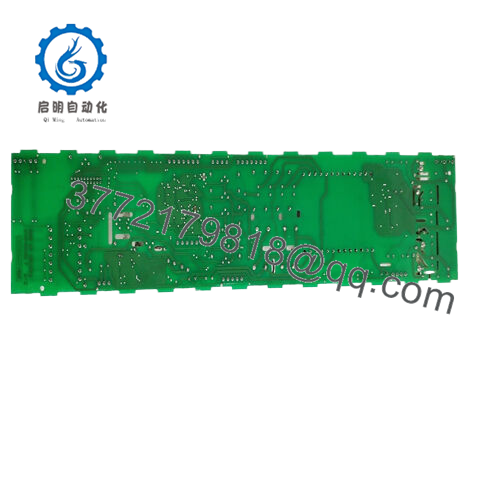

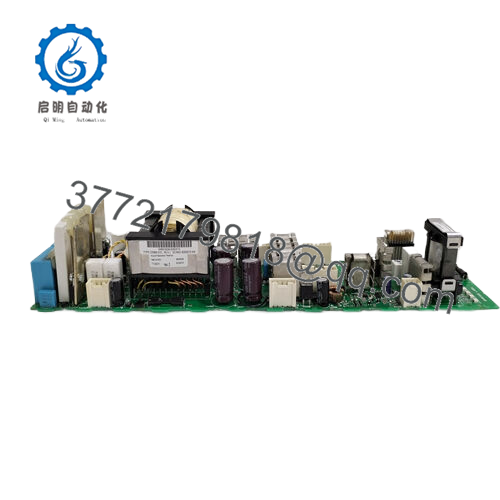

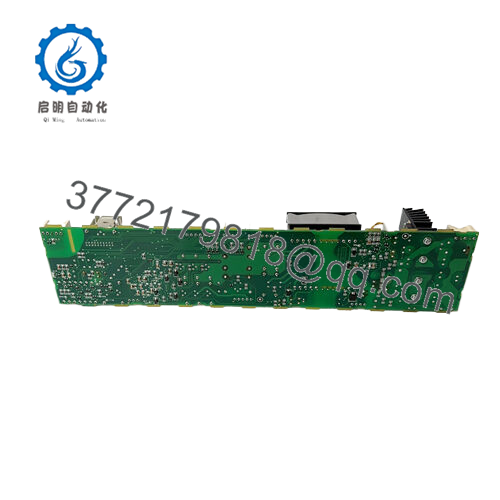

DSMB-01C Product Description:

DSMB-01C is a compact motor protection and control module designed specifically for low-voltage three-phase motors (up to 400 V AC, 60 A). As part of ABB’s drive and motor control product portfolio, it serves as an intelligent relay that integrates motor start stop functionality and advanced protection features. This module is connected to PLC or distributed control system (DCS) through digital input/output interface, supporting remote control and monitoring of motor status (such as running, fault, ready).

DSMB-01C

In the automation architecture, DSMB-01C serves as the interface between the control system and the motor, ensuring safe operation and providing diagnostic insights. For system integrators, this module simplifies panel design by integrating multiple components into a single DIN rail mounting unit, reducing wiring complexity and space requirements. Its value proposition lies in combining basic motor control with advanced protection algorithms, suitable for both independent applications and large-scale systems that require predictive maintenance and energy management.

DSMB-01C

Main features and advantages:

Comprehensive motor protection: This module provides overload protection (thermal model), phase failure detection, undervoltage/overvoltage protection, and stall detection, in compliance with IEC 60947-4-1 standard. Advanced features such as starting current monitoring help identify mechanical issues during motor debugging, while dynamic thermal memory can adapt to different load curves to prevent false tripping during intermittent operations.

Flexible control options: DSMB-01C supports local (button) and remote (PLC/DCS) control, with digital inputs configurable for start stop commands, jog, and emergency stop. Its built-in timer function supports adjustable start stop delay and is suitable for sequential control of multiple motors. The relay output of the module can be connected to contactors, indicator lights, or alarms to provide visual feedback to the maintenance team.

State monitoring insight: Real time monitoring of motor current, voltage, and power consumption enables engineers to detect early signs of wear, such as phase imbalance or resistance rise. Fault logs and event records (such as the last 50 trips) help diagnose repetitive issues, while configurable analog outputs (4-20 mA) can transmit motor health data to the SCADA system for trend analysis. This proactive approach can reduce maintenance costs by up to 30% in predictive maintenance scenarios.

Durable industrial design: This module is capable of withstanding vibrations (5 g, IEC 60068-2-6) and temperatures ranging from -25 ° C to+60 ° C, making it suitable for harsh environments. Its compact size (45mm width) optimizes the space utilization of the control panel, while the screw free terminal block simplifies wiring and reduces installation time. The IP20 protection level of the module can prevent dust and accidental contact, ensuring reliability in manufacturing workshops or outdoor installations.

DSMB-01C

Technical specifications:

Model DSMB-01C

Brand ABB

Type Motor Protection and Control Module

Voltage range 230-400 V AC (three-phase), 50/60 Hz

Current range 0.5-60 A (adjustable through software)

Protection functions include overload, phase failure, undervoltage/overvoltage, locked rotor, and short circuit

Control input: 3-channel digital input (24 V DC, charging/pulling current)

Control output 2-channel relay (single pole double throw, 250 V AC/30 V DC, 5 A)

Communication Modbus RTU (optional, via additional module)

Working temperature -25 ° C to+60 ° C

Installation method DIN rail (TS 35/7.5)

Dimensions 45 mm (width) x 125 mm (height) x 100 mm (depth)

Weight 0.3 kg

Certification CE, UL, IEC 60947-4-1

Environmental protection level IP20, IEC 61000-6-2 (EMC compatible)

Contact Us

Mobile:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

DSMB-01C

Application areas:

In industrial automation systems that require reliable motor control and protection, DSMB-01C is a key component for managing three-phase asynchronous motors, particularly suitable for harsh environments such as mining, oil and gas, and heavy industry. This motor protection and control module ensures stable operation of motors that drive equipment such as pumps, compressors, conveyors, and fans. For example, in mining operations, DSMB-01C can monitor the current, voltage, and temperature of the conveyor belt motor in real time, trigger protective shutdown in case of overload or phase failure, and prevent equipment damage from causing high losses. In sewage treatment plants, it can control the start stop sequence of sludge pump motors and provide advanced diagnostic functions to predict bearing wear or insulation aging.

The universality of this module is also reflected in applications that meet safety standards, such as emergency stop integration in food processing production lines or applications in explosion-proof environments in chemical plants. By integrating motor control, protection, and status monitoring functions into a single device, DSMB-01C effectively addresses the core challenges of reducing unplanned downtime and optimizing energy efficiency. Engineers attach great importance to its ability to reduce panel complexity, as it replaces independent relays, timers, and thermal overload protectors with a centralized intelligent solution.

DSMB-01C

Related product introduction:

DSQC 1030- ABB’s motor control circuit breaker, when used in conjunction with DSMB-01C, enhances short-circuit protection for high-risk applications.

ACS580 driver – ABB frequency converter, used for motor speed regulation, can be integrated with DSMB-01C, suitable for applications that require protection and variable torque.

PM590-ETH – ABB PLC module, used for advanced logic control, can achieve complex motor sequence control and interlocking with DSMB-01C.

TA541- Terminal adapter, used for motor connection cables, simplifies wiring between modules and motors or contactors.

CM572- Modbus RTU communication module, supports remote monitoring of DSMB-01C through SCADA system or HMI.

PS501-24 V DC power supply ensures stable voltage supply for control inputs/outputs of modules in non redundant systems.

Installation and maintenance:

Precautions before installation:

Ensure that the full load current (FLC) of the motor is within the adjustable range of the module (0.5-60 A), and configure the current rating through the DIP switch or software of the module.

Separate the wiring of power cables (motor power supply) and control cables (PLC signals) to reduce electromagnetic interference (EMI). If a Modbus module needs to be added, shielded twisted pair cables should be used for the communication link.

Install the module in a well ventilated control cabinet, leaving at least 25mm of space on both sides for heat dissipation, especially in high-temperature environments.

Maintenance suggestion:

Perform visual inspection every quarter: check for loose terminal connections, especially motor power leads, and ensure that the module’s status indicator light displays normally (such as the green “ready” light).

Conduct annual load testing: simulate fault conditions (such as phase failure, overload) to verify the protection response of the module, and record the results for compliance auditing.

Update the firmware of the module every two years (if applicable) to include error fixes or new features, and review the motor maintenance logs to associate module diagnostics with physical checks (such as bearing replacement).

In a dusty environment, clean the ventilation openings of the module with compressed air to prevent heat accumulation, and check the corrosion of the terminal block in a humid environment.

Other ABB product models:

ABB PM861AK01 3BSE018157R1

ABB PM633 3BSE008062R1

ABB Al630 3BHT300011R1

ABB 3BHL000986P3003 5SDF1645L0006

ABB 3BHB004744R0010

ABB 3BSE023732R1

ABB PU519 3BSE018681R1

ABB PM877 3BDH000777R1

ABB 83SR51R1210 GJR2396200R1210

ABB AO2000 LS25

ABB 1SDA053999R1

ABB CI854BK01 3BSE069449R1

ABB DI830 3BSE013210R1

ABB PM645B

ABB 3BHE035301R0001 UNS 0121 A-Z,V1

ABB 3BHE035301R1002 UNS 0121A-Z,V1

ABB AO810V2

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101

ABB XVC517AE10 3BHB004744R0010

ABB UFC760BE1042 3BHE004573R1042

ABB UFC760BE141 3BHE004573R0141

ABB NAVIGATOR 600 V20

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626