Description

The DRL-DPM-BKF is an industrial-grade communication module primarily used in automation systems for reliable data exchange within control architectures. It is widely employed in industrial automation environments where real-time, high-speed communication with PROFIBUS-DP devices is crucial. Industries such as manufacturing, process control, and building automation benefit from the module’s capacity to maintain network integrity and support various network topologies including ring, star, chain bus, and hybrid structures. The DRL-DPM-BKF is designed to handle the complexities of redundant communication networks, which helps prevent downtime and ensures continuous operation of critical control systems.

In practical terms, this product supports automation engineers and system integrators in environments where maintaining communication between sensors, actuators, and controllers is vital. It excels in scenarios demanding robust data acquisition, control signal transmission, and automatic device detection within the PROFIBUS-DP protocol framework. Its dual electrical and fiber interface design enhances network reliability, making it applicable in harsh industrial settings where electromagnetic interference and physical damage risks are elevated. The DRL-DPM-BKF is therefore essential in facilitating seamless control system operation across various industrial sectors.

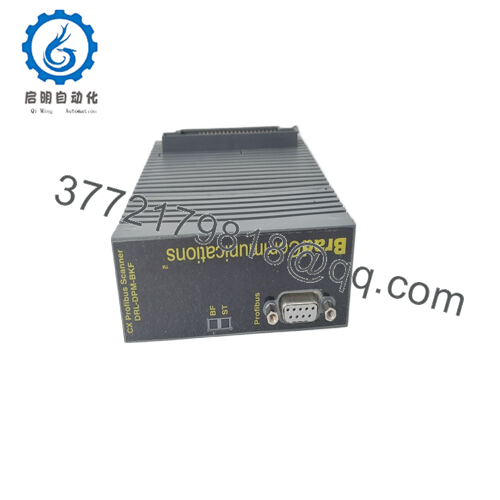

The DRL-DPM-BKF is a communication interface module that adheres to the PC/104 standard and specializes in PROFIBUS-DP network communications. This module serves as a critical component within industrial control systems, functioning as a data gateway that bridges field devices with central controllers. Its role is to enable smooth data transmission at rates up to 12 Mbps, accommodating the real-time control and monitoring needs distinctive to automation networks.

Fitting into architectures built on PROFIBUS-DP protocols, the DRL-DPM-BKF integrates dual electrical and dual fiber optic interfaces, supporting network redundancy and multiple network configurations such as star, ring, or hybrid topologies. This gives engineers flexibility in designing fault-tolerant control systems. The module’s seamless compatibility with widely used industrial automation platforms makes it a preferred choice for integrators seeking reliable, maintainable, and scalable communication infrastructure.

- DRL-DPM-BKF

- DRL-DPM-BKF

The DRL-DPM-BKF prides itself on delivering high-performance, real-time communication capabilities essential for modern industrial automation. With support for PROFIBUS-DP communication speeds up to 12 Mbps, it ensures swift data exchanges between controllers and peripheral field devices. The dual electrical and fiber interfaces facilitate versatile network designs, ensuring robust data integrity and minimizing the risk of communication failures in noisy industrial environments.

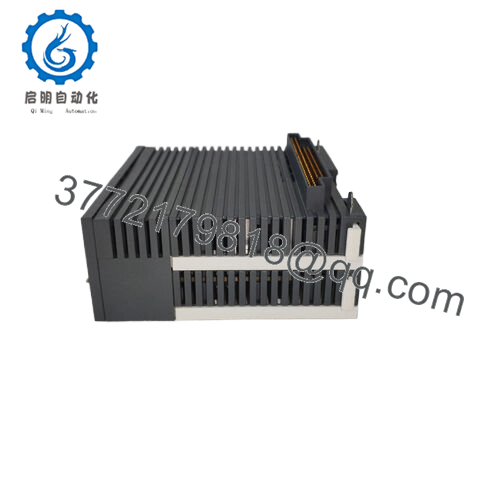

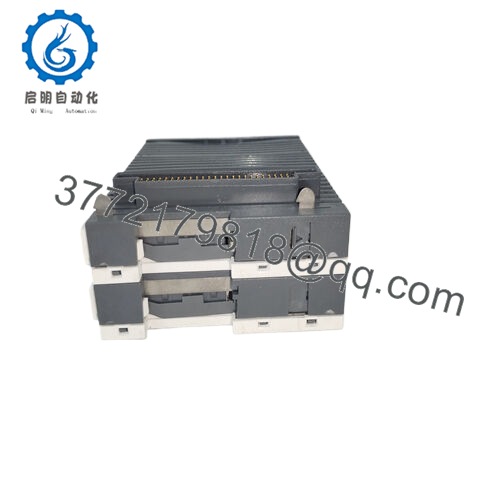

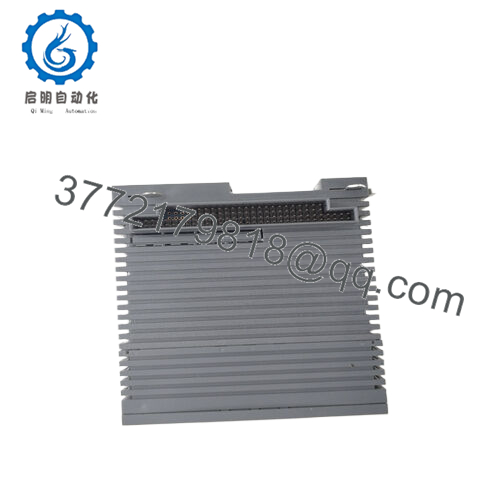

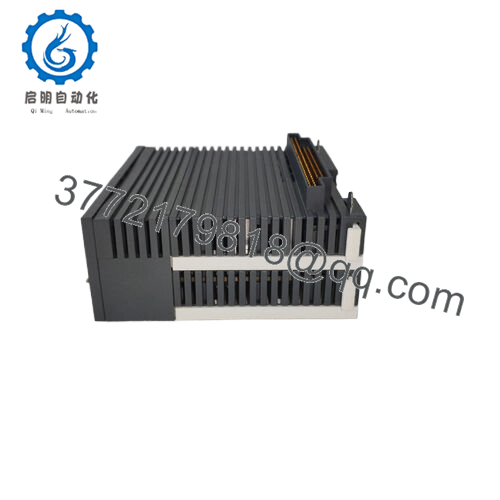

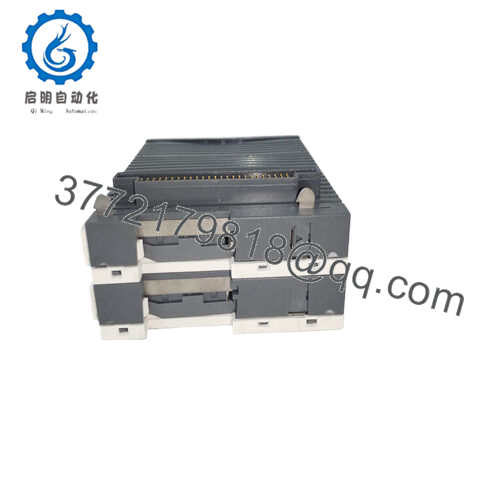

Structurally, the module is designed for rugged industrial use, adhering to the compact PC/104 form factor. Its solid construction allows easy mounting in control cabinets with minimal space requirements. The inclusion of fiber optic interfaces alongside traditional electrical connections enhances its utility in installations where network redundancy and long cable runs pose challenges.

Reliability of the DRL-DPM-BKF is enhanced through its support for redundant network configurations—critical in applications where system uptime is mandatory. Diagnostics and automatic device detection features streamline maintenance, enabling quick identification and resolution of network issues. Altogether, the module’s design prioritizes consistent data flow, durability, and network resilience, meeting the demanding requirements of industrial automation professionals.

| Parameter | Value |

|---|---|

| Model | DRL-DPM-BKF |

| Brand | Bard Communications / Molex |

| Product Type | PROFIBUS-DP Communication Module |

| Data Transmission Rate | Up to 12 Mbps |

| Input Channels | 16 Digital (24 V DC) |

| Output Channels | 8 Relay (5 A @ 250 V AC) |

| Interfaces | Dual electrical and dual fiber optic |

| Mounting | PC/104 standard form factor |

| Operating Temperature | Industrial rated (typically -20 °C to +70 °C) |

| Weight | Approx. 0.3 kg |

| Network Topologies Supported | Star, Ring, Chain Bus, Hybrid |

| Certifications | Industrial grade |

Related modules often used alongside the DRL-DPM-BKF include the BARD PC104-DPIO, which provides additional digital input/output capabilities for expanded control functionality.

The HIMA F7131 power supply monitoring unit integrates well in safety and control architectures paired with communication modules like the DRL-DPM-BKF.

The F8650 and F8651 modules offer centralized diagnostic and control features that complement the communication backbone.

The Molex DRL-DPM-BKF-B variant offers similar functions under different industrial specifications. These modules collectively form a robust ecosystem for reliable industrial communication and control.

Installation of the DRL-DPM-BKF requires careful consideration of the control system architecture and physical mounting conditions. Due to its PC/104 form factor, it demands precise alignment and secure fastening within rack or cabinet spaces designed to accommodate compact industrial modules. Electrostatic discharge protections should be observed during handling to prevent damage to sensitive components. Ensuring appropriate cable layout and separation between fiber and electrical lines reduces electromagnetic interference and maintains signal quality.

Maintenance should focus on regular inspection of communication lines and status indicators on the module to detect faults early. Network diagnostics tools compatible with PROFIBUS-DP protocols assist in verifying module operation and diagnosing connectivity issues. Firmware should be updated periodically following manufacturer guidelines to sustain compatibility and incorporate improvements. These practices extend the service life of the DRL-DPM-BKF and enhance system reliability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626