Description

1. What This Product Solves

In the demanding world of industrial automation, maintaining precise control over electrical loads while ensuring signal reliability and system stability is often the difference between smooth operations and costly downtime. Engineers frequently face challenges like galvanic isolation between low-voltage control signals and high-power actuators, where noise interference or voltage spikes can compromise process control accuracy. This is especially critical in environments requiring high reliability, such as distributed control systems (DCS) or programmable logic controller (PLC) setups, where even minor signal disruptions lead to production halts or safety risks. The DR1008B-230 addresses these pain points head-on by delivering robust relay-based output management for I/O signals, enabling seamless switching of diverse loads without compromising the integrity of your core automation infrastructure.

Consider typical scenarios: a manufacturing line where motors and solenoids need instantaneous on/off control tied to sensor feedback, or a water treatment facility monitoring valve positions amid fluctuating power conditions. Here, the DR1008B-230 steps in as an essential component, providing the electrical isolation needed to protect sensitive PLC inputs from back-EMF or inductive transients. Its design prioritizes modular integration, allowing you to scale I/O capacity without overhauling existing backplanes. In process control applications, where uptime is non-negotiable, this module ensures consistent performance by handling high inrush currents reliably, reducing the risk of relay chatter or premature wear. By focusing on user goals like enhanced system stability and minimized wiring complexity, the DR1008B-230 empowers teams to deploy solutions that adapt to evolving automation needs, whether in retrofits or greenfield projects. Ultimately, it transforms potential vulnerabilities into strengths, letting you concentrate on optimization rather than firefighting electrical gremlins. This level of dependability isn’t just a feature—it’s a strategic enabler for achieving operational excellence in industrial automation landscapes.

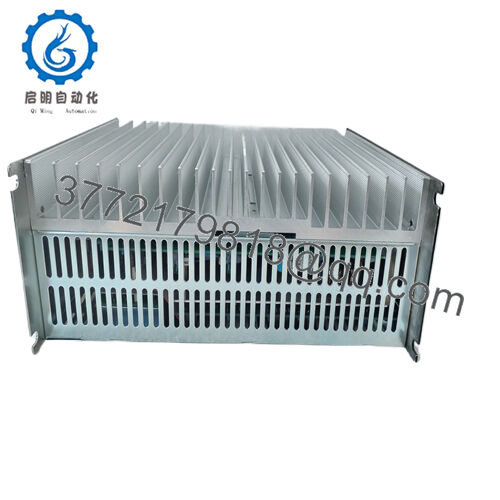

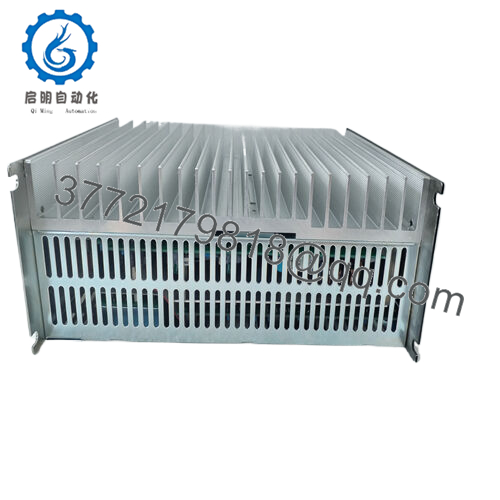

- DR1008B-230

2. How the Product Works & Fits into a System

At its core, the DR1008B-230 functions as a digital output relay module, translating low-level control commands from a central processor into high-power switching actions for field devices. Picture it as the reliable intermediary in your I/O architecture: it receives digital signals—typically 24V DC—from a PLC or DCS controller via a standard backplane or fieldbus interface, then uses its onboard electromechanical relays to energize or de-energize connected loads like pumps, heaters, or indicator lights. This isolation is key; the module’s relays create a physical break between the control side and the power side, preventing ground loops or surges from propagating back to your sensitive electronics.

Integration-wise, the DR1008B-230 slots neatly into modular control platforms, such as DIN-rail mounted enclosures common in SCADA systems or remote I/O racks. It communicates over protocols like Modbus RTU or PROFIBUS, depending on your setup, allowing diagnostics like relay status monitoring or fault logging to feed directly into your HMI for proactive maintenance. Redundancy support comes through its multi-channel design—eight independent outputs mean you can daisy-chain modules for expanded capacity without single points of failure. In a typical stack, it might sit downstream from analog input modules, handling the “actuate” phase of a control loop: for instance, a temperature controller detects a setpoint deviation, signals the DR1008B-230, and the module switches a cooling fan accordingly.

What makes it user-friendly in real deployments is the straightforward interaction—no proprietary software required for basic ops, just standard screw terminals for load wiring and LED indicators for at-a-glance verification. Whether you’re building out a safety interlock system or a batch processing sequencer, this module enhances the overall I/O architecture by supporting hot-swappable relays for quick field repairs and built-in surge suppression to handle inductive kicks. It’s positioned not as a standalone gadget but as a scalable building block, ensuring your automation stack remains flexible as demands grow—from discrete manufacturing to continuous processes.

3. Technical Highlights Summary (Table)

| Specification | Details |

|---|---|

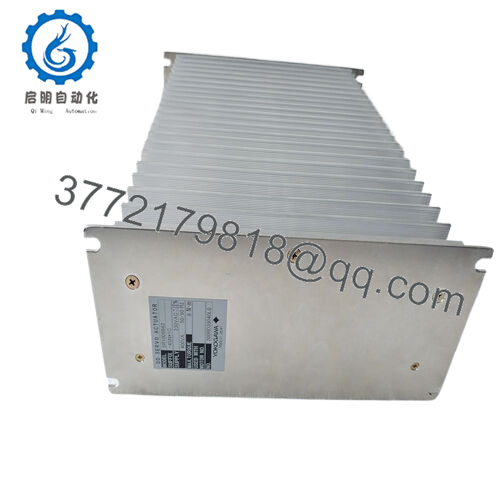

| Model Number | DR1008B-230 |

| Brand | Generic Industrial (OEM) |

| Type | 8-Channel Digital Relay Output Module |

| Input Voltage | 24V DC (control) |

| Operating Temp Range | -20°C to +60°C |

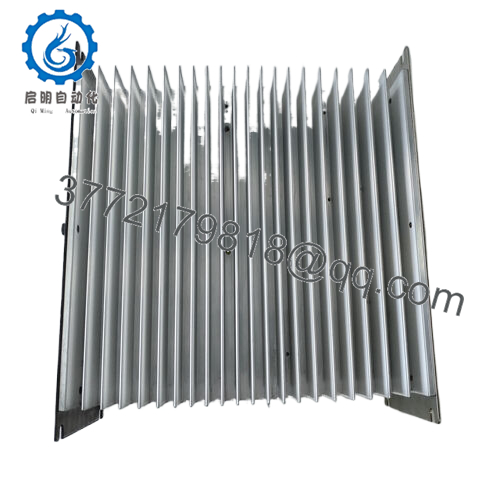

| Mounting Style | DIN Rail (35mm) |

| Dimensions | 160mm x 80mm x 60mm |

| Weight | 0.45 kg |

| Interface/Bus | Screw Terminals / Fieldbus Compatible |

| Compliance | CE, RoHS, UL |

| Supported Protocols | Modbus RTU, PROFIBUS |

| Typical Power Draw | 2.5W |

4. Real-World Benefits

Choosing the DR1008B-230 means investing in a component engineered for the long haul, where reliability translates directly to fewer unplanned stops and more predictable throughput. In high-stakes process control environments, its galvanic isolation ensures that transient noise from heavy machinery doesn’t cascade into control errors, preserving the accuracy of your I/O signals over extended runs. This isn’t about flashy specs; it’s about the quiet confidence that comes from relays rated for millions of cycles, which keep your system humming without the engineering overhead of constant recalibrations or replacements. Maintenance teams appreciate how this reduces troubleshooting time—built-in diagnostics flag issues early, so you’re addressing root causes rather than symptoms.

Performance consistency shines through in variable conditions, like fluctuating ambient temperatures or dusty shop floors, where the module’s rugged enclosure maintains contact integrity without derating output capacity. It ensures long-term performance by minimizing heat buildup during high-duty applications, allowing you to push loads closer to their limits without risking thermal shutdowns. For integration ease, the DR1008B-230 cuts down on custom cabling needs; its standardized terminals pair effortlessly with existing panels, freeing up design hours for value-added tweaks like advanced sequencing logic.

Beyond the basics, this module streamlines scalability—add channels as your automation footprint expands, without ripping out the backbone. The result? Lower total cost of ownership through reduced wiring errors and faster commissioning, plus the peace of mind from compliance certifications that align with global standards. In essence, deploying the DR1008B-230 shifts your focus from reactive fixes to strategic gains, like optimizing energy use in load switching or enhancing safety in interlocked sequences. It’s the kind of thoughtful engineering that compounds benefits over years, turning a solid module into a cornerstone of efficient, resilient operations.

5. Typical Use Cases

The DR1008B-230 thrives in process control environments where critical system uptime demands unwavering signal reliability, such as in power plants managing turbine starters or emergency shutdown valves. In these setups, its eight relay channels handle fast data cycles for synchronizing multiple actuators, ensuring precise timing even under high inrush loads—vital for preventing overloads during peak generation phases. Harsh conditions like vibration from rotating equipment are no match for its secure DIN-rail mounting, delivering consistent performance that supports 24/7 operations without faltering.

Shifting to manufacturing automation, the DR1008B-230 is a go-to for assembly lines in the automotive sector, where it controls pneumatic grippers and conveyor diverters based on PLC commands. Here, the need for continuous uptime is paramount; the module’s isolation protects against EMI from welding arcs, while its diagnostic LEDs enable quick visual checks during shift handovers. Engineers value how it integrates into I/O signal chains for modular expansions, scaling from pilot prototypes to full-scale production without downtime.

In wastewater treatment facilities—classic process control environments—the DR1008B-230 excels at regulating pumps and aeration blowers amid corrosive atmospheres and variable humidity. Its high reliability shines in extended duty cycles, switching loads reliably to maintain flow rates and chemical dosing accuracy. These deployments highlight the module’s versatility: whether combating harsh conditions with robust contacts or ensuring fast response in safety-critical loops, the DR1008B-230 bolsters overall system resilience, making it indispensable for industries prioritizing efficiency and safety.

6. Compatible or Alternative Products

DR1004B-230 – Compact 4-channel variant for space-constrained panels with lighter load requirements.

DR1016B-230 – Expanded 16-output model ideal for high-density I/O in large-scale DCS setups.

DR1008B-024 – Low-voltage counterpart (24V DC coil) suited for battery-backed or mobile automation systems.

SSR1008B-230 – Solid-state relay alternative offering silent operation and higher cycle rates for noise-sensitive applications.

DR1008B-HI – High-current edition (up to 16A per channel) for demanding inductive loads like large solenoids.

DR0808B-230 – Economy version with basic diagnostics, perfect for cost-optimized retrofits.

MDR1008B-Modbus – Enhanced model with native Modbus TCP for seamless Ethernet integration in IIoT environments.

7. Setup Notes & Maintenance Insights

Before sliding the DR1008B-230 onto your DIN rail, double-check bus compatibility—ensure your PLC’s output specs align with the module’s 24V DC control inputs to avoid handshake issues down the line. Allocate adequate cooling space around it, especially if stacking multiple units, as ambient airflow prevents any localized hot spots during prolonged high-load switching. Firmware readiness matters too; if your system uses PROFIBUS, verify the segment’s terminator settings to sidestep communication dropouts. Grounding is non-negotiable—tie the module’s shield terminal to your cabinet’s earth bus for optimal surge protection, and torque those screw terminals to spec (around 0.5-0.6 Nm) to secure field wiring without stripping.

Ongoing maintenance keeps things straightforward and infrequent. Start with monthly LED status reviews: green for active channels, amber for faults—log any patterns to predict relay life. Quarterly, inspect connectors for corrosion or looseness, particularly in humid spots; a quick continuity test with a multimeter across outputs confirms no creepage. For deeper checks, swap in a spare relay annually during planned outages— the pluggable design makes this a 5-minute job, no tools beyond a screwdriver. If you’re running diagnostics via software, pull reports every six months to track cycle counts; exceeding 80% of rated life? Budget for refresh. This proactive rhythm minimizes surprises, extending the module’s service interval to 5+ years in moderate-duty apps. Think of it as routine calibration for your I/O backbone—practical steps that pay off in sustained reliability without pulling techs off critical paths.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626