Description

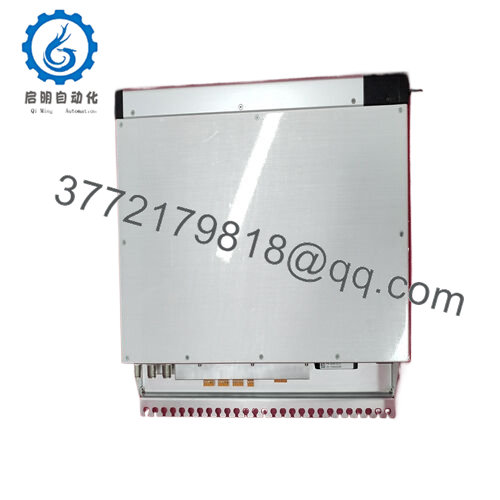

Product Model: DPS112

Product Brand: Generic Industrial Automation

Product Series: DPS Series

Product Features:

- Robust industrial design for continuous operation

- High compatibility with standard PLC and DCS platforms

- Optimized for fast signal processing and reliable data handling

- Compact form factor ideal for modular control panels

- DPS112

Applications & Industry Context

In real-world automation plants, efficiency is often won or lost at the module level. The DPS112 has earned its reputation in environments where reliability and response time are non-negotiable. It is commonly deployed in manufacturing facilities, power generation systems, and material handling plants, where it acts as a key processing or interface module within a larger automation framework.

One of the strongest indicators of the DPS112 module’s versatility is its adoption across multiple industries. For instance, in chemical processing, engineers rely on it to maintain stable control loops under fluctuating temperature and pressure conditions. In automotive assembly lines, the same module handles synchronized control of conveyor belts, robotic arms, and vision systems. Meanwhile, in food and beverage packaging, the unit manages timing-critical sequences that must adhere to safety and sanitation standards.

Maintenance teams appreciate that DPS112 units are built for demanding 24/7 operation. Downtime in automation environments can easily translate into significant production losses, and components like the DPS112 help mitigate those risks through durable electronic design and predictable performance. Even in facilities with high electrical noise or vibration, it continues to operate with remarkable stability.

Beyond industrial plants, some system integrators have also integrated the DPS112 into building automation and energy management systems, using it as a flexible I/O processing node or communication interface. Whether it’s maintaining HVAC logic in a smart building or coordinating turbine signals in a power plant, this module’s reliability ensures smooth, uninterrupted control operations.

Technical Features & Benefits

From a technical standpoint, the DPS112 represents a balanced blend of design simplicity and advanced capability. Its core processor handles fast scan cycles, allowing real-time responses to rapidly changing input conditions. Engineers who work with distributed systems appreciate that the DPS112 can easily communicate with existing controllers via industry-standard protocols, ensuring straightforward integration without complex reprogramming.

Internally, the module features an optimized circuit layout that reduces electrical noise susceptibility. The use of high-grade capacitors and solid-state components ensures both thermal stability and longevity. Unlike some lower-end alternatives, the DPS112 is designed for environments where sustained high temperature and electrical load are expected.

Ease of configuration is another standout advantage. The module typically supports plug-and-play recognition within compatible racks, minimizing the need for manual addressing. When combined with intuitive configuration tools, engineers can quickly set up or replace a DPS112 with minimal disruption to production.

Reliability also extends to the power handling side. With robust protection against short-circuits, surges, and overloads, the DPS112 maintains operational continuity even under unstable power conditions. Many users note that this resilience translates directly into reduced service calls and longer system uptime.

Performance benchmarks often show the DPS112 achieving excellent mean time between failures (MTBF) figures, which underscores its reputation for long-term dependability. The module’s thermal management design, featuring efficient heat dissipation through an integrated metal baseplate, allows continuous operation in compact control cabinets where airflow may be limited.

Overall, the DPS112 gives automation engineers confidence that their system backbone — from process control to signal management — remains solid and predictable even under load.

Technical Specifications

| Specification | Description |

|---|---|

| Model | DPS112 |

| Type | Industrial Automation / Processing Module |

| Input Voltage | 24 VDC nominal |

| Power Consumption | Approx. 8–12 W |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -25°C to 85°C |

| Communication Ports | RS-485 / Ethernet (depending on configuration) |

| Mounting Type | DIN rail or panel mount |

| Dimensions | 120 mm × 80 mm × 40 mm |

| Weight | 0.45 kg |

| Signal Processing Rate | 1 ms typical scan time |

| Protection | Over-voltage, short-circuit, and reverse polarity |

| Certifications | CE, RoHS compliant |

| Maintenance Cycle | Recommended inspection every 24 months |

Product Role & System Fit

The DPS112 acts as the nerve center in mid-level control systems. It often serves as an interface between field devices and higher-level PLCs or DCS platforms. In modular architectures, the DPS112 can perform both signal conditioning and control logic processing, effectively bridging the gap between raw sensor data and actionable control outputs.

In practical applications, technicians appreciate how easily the DPS112 fits into existing automation cabinets. Its compact footprint leaves room for additional modules, while its standardized connectors allow for seamless wiring alongside other control equipment. Whether used as a stand-alone node or as part of a redundant setup, it contributes to system flexibility and scalability.

Compatibility remains one of its strongest attributes. The DPS112 communicates effortlessly with a variety of standard automation networks. Integrators often highlight its “drop-in” adaptability when replacing outdated hardware. This ease of integration reduces engineering hours and minimizes system downtime during upgrades.

Additionally, the DPS112 supports advanced diagnostic capabilities. Built-in LED indicators provide real-time feedback on status, power, and communication, allowing technicians to quickly identify issues. These user-friendly features make the module particularly appealing in environments where quick visual verification of module health is crucial.

Installation & Maintenance Insights

Installing a DPS112 module is straightforward, yet attention to detail ensures optimal performance and longevity. Mounting the unit on a properly grounded DIN rail helps minimize electrical interference. Before wiring, technicians should verify polarity and voltage levels to prevent damage. Proper cable management is equally important, especially in panels with dense wiring layouts.

During installation, engineers often perform a quick continuity and insulation resistance test on the wiring harness. This step prevents potential faults once the DPS112 goes live. Once installed, configuration typically involves setting up the communication parameters and verifying the module’s status through the control system interface.

For maintenance, periodic inspection is recommended to check for dust accumulation and to ensure ventilation paths remain clear. Cleaning with a soft, dry brush or compressed air is usually sufficient. Firmware or configuration updates, if supported, can be applied through the system’s engineering software to maintain compatibility with evolving control networks.

Users often report that even after several years of operation, the DPS112 maintains its performance characteristics with minimal drift. Replacement, when eventually needed, is quick — simply unlatch the old module, slide in the new one, and the system recognizes it automatically. That kind of serviceability is a quiet but critical reason for its popularity in continuous process industries.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626