Description

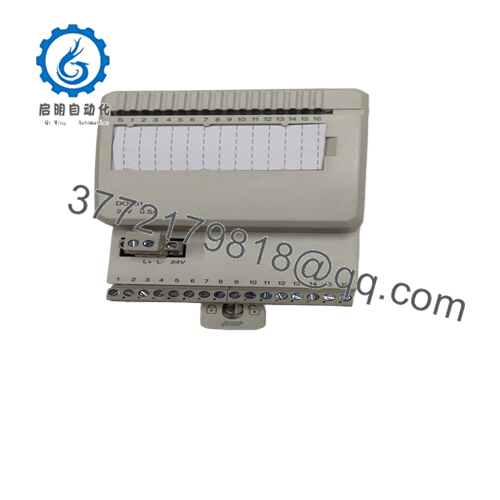

| Model | DO801 |

| Brand | ABB |

| Type | Digital Output Module |

| Number of Channels | 8 |

| Output Voltage | 24 VDC |

| Maximum Output Current | 2 A per channel (5 A total) |

| Isolation | Groupwise isolated from ground |

| Response Time | < 1 ms (turn on/off) |

| Short-Circuit Protection | Current-limited, automatic recovery |

| Overload Protection | Thermal shutdown with recovery |

| Maximum Field Cable Length | 600 meters (656 yards) |

| Rated Insulation Voltage | 50 V |

| Dielectric Test Voltage | 500 V AC |

| Power Dissipation | Typ. 3.2 W |

| Current Consumption | 120 mA at 5 V module bus |

| Diagnostics | LED indicators for fault, run, warning, and individual channels |

| Operating Temperature | -40°C to +70°C (-40°F to +158°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity | 5% to 95%, non-condensing |

| Protection Class | IP20 |

| EMC Compliance | EN 61000-6-4, EN 61000-6-2 |

| Compatible MTUs | TU 810, TU 812, TU 814, TU 830 |

| Keying Code | AB |

| Dimensions | 45 mm (W) x 102 mm (D) x 119 mm (H) |

| Weight | 0.23 kg (0.51 lbs) |

DO801

The ABB DO801 is a high-performance digital output module engineered for industrial automation systems that require precise control of discrete actuators and devices. As a key component of ABB’s System 800 I/O family, it integrates seamlessly into existing control architectures, acting as the critical link between central processing units and field equipment.

DO801

This module provides 8 digital output channels, converting control signals from the system into voltage outputs capable of driving external devices. What makes the ABB DO801 valuable for system integrators and plant engineers is its balanced design—combining reliable switching capabilities with rugged construction and space-efficient packaging. It fits naturally within ABB’s ecosystem of I/O modules, complementing digital input modules like the ABB DI810 to create complete control loops for monitoring and actuation.

DO801

Main features and advantages:

The ABBDO801 stands out for its robust output drive capabilities, delivering stable 24V DC signals capable of handling up to 2A per channel—sufficient for powering solenoids, small motors, and indicator panels common in industrial settings. Its advanced protection features include short-circuit and overload protection, preventing module damage when connected devices draw excessive current—a crucial safeguard in complex installations where wiring errors can occur. The module’s groupwise isolation protects both the control system and connected devices from voltage transients, enhancing system reliability in environments with high electrical noise.

Despite its powerful output capabilities, the ABB DO801 maintains a compact footprint, optimizing control cabinet space utilization. Its rugged design allows operation across a wide temperature range (-40°C to +70°C), withstanding the thermal variations typical in industrial environments. The module’s hot-swappable design enables replacement without powering down the entire control system, minimizing downtime during maintenance—a feature highly valued in continuous process industries where operational interruptions are costly.

DO801

Application areas:

In industrial automation systems, the ability to reliably actuate devices based on control logic is as critical as accurate signal monitoring. Manufacturing lines, material handling systems, and process control environments depend on precise activation of solenoid valves, contactors, and indicator lights to maintain operational efficiency. Engineers face the challenge of ensuring these output signals remain stable in electrically noisy environments while fitting within constrained cabinet space. This is where the ABB DO801 excels, serving as a robust digital output module that bridges control systems and field devices across diverse industrial applications. Used in distributed control systems (DCS) and PLC architectures, the ABB DO801 delivers consistent switching performance, making it a trusted component in applications requiring reliable actuation and control.

DO801

Related products:

DI801 – Complementary digital input module, pairs with ABB DO801 to create complete 8-channel I/O control loops for monitoring and actuation.

DO810 – Higher-density (16-channel) counterpart, works alongside ABB DO801 in applications needing mixed output channel counts.

AO801 – Analog output module that extends system capabilities by combining discrete control from ABB DO801 with proportional output signals.

AC 800M Controller – Central processing unit that sends control signals to ABB DO801 for actuation of field devices.

TB801 Terminal Block – Dedicated connection interface for ABB DO801, simplifying wiring with secure termination for 8 output channels.

CI853A – Communication interface module enabling data transfer between ABB DO801 and higher-level industrial networks.

PM863 Processor Module – Works with ABB DO801 to generate control signals for medium-scale automation systems.

DI810 – 16-channel digital input module that integrates with ABB DO801 in systems requiring expanded monitoring capabilities alongside control outputs.

DO801

Installation and maintenance:

Before installing the ABB DO801, ensure the control cabinet provides adequate ventilation, as power-dissipating modules require airflow—maintain at least 20mm clearance around the module. Verify proper grounding of the mounting rail and backplane to maximize noise immunity, critical for stable output signals. Calculate total current draw across all 8 channels to ensure it does not exceed the 5A total limit, distributing high-current devices across multiple modules if necessary. Use shielded twisted-pair cables for field wiring and maintain 150mm separation from power cables to prevent interference with ABB DO801 operation. Confirm terminal block compatibility and follow recommended torque specifications (0.5–0.6 Nm) for all connections.

For maintenance of the ABB DO801, perform quarterly visual inspections to check for dust accumulation on ventilation surfaces and verify secure connections. Use system diagnostic software monthly to test output channel responsiveness, checking for stuck-on or unresponsive channels before they affect operations. During scheduled shutdowns, inspect terminal blocks for signs of overheating (discoloration) which may indicate loose connections or overload conditions. When replacing the ABB DO801, ensure firmware versions match other system modules to maintain communication compatibility. Document typical current draw for each channel during normal operation to create baselines for troubleshooting overload conditions.

Other ABB product models:

ABB FI830F

ABB FI840F

ABB FPR3203526R1002A

ABB FPR3600227R1202-J 07KR31

ABB FS300R12KE3/AGDR-72C

ABB FS450R12KE3/AGDR-71C

ABB FSA80

ABB G2000A5.7ST

ABB GCC960C102 3BHE033067R0102

ABB GDB021BE HIEE410455P104

ABB GDB021BE01 HIEE300766R0001

ABB GDC801B 3BHE051592R0101

ABB GDC801B102 3BHE051592R0102

ABB GFD233A 3BHE022294R0101

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GFD563A102 3BHE046836R0102

ABB GJR5252300R0101 07AC91

ABB GJR5252300R3101 07AC91

ABB GJR5252300R3101 07AC91

ABB GJR5253100R0270 07KT98

ABB GLBS200516R

ABB GMKP2800-32IBY

ABB GNT0104500R0002

ABB GRBTU 3BSE013175R1

ABB GVC750BE101 3BHE009681R0101 GVC750BE101 3BHE013088R001 5SHY3545L0010

ABB HAI805

ABB HBFFAEAGNBA1BAA11G

ABB HBS01-EPD

ABB HBS01-EPD

ABB HC800

ABB HESG112548R12

ABB HESG324430R11/B 216GD61A

ABB HESG324442R0112

ABB HESG447419R0001 70EA05a-E

ABB HIEE205011R0002(UNS3670A)

ABB HIEE205014R0001 UNC4673A, V1

ABB HIEE205014R1 HI220856-312/20 UNC4673AV1

ABB HIEE300698R0001(KUC321AE)

ABB HIEE300888R0002 UAC389AE02

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626