Description

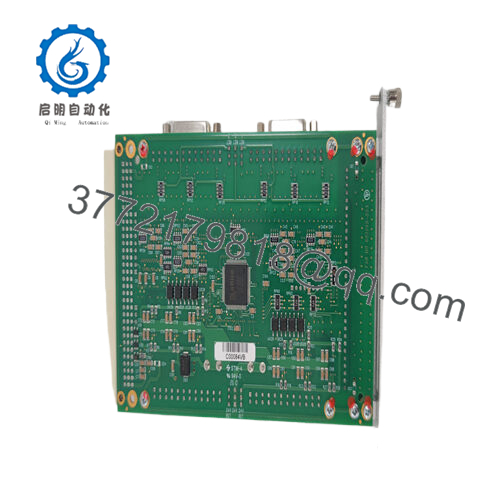

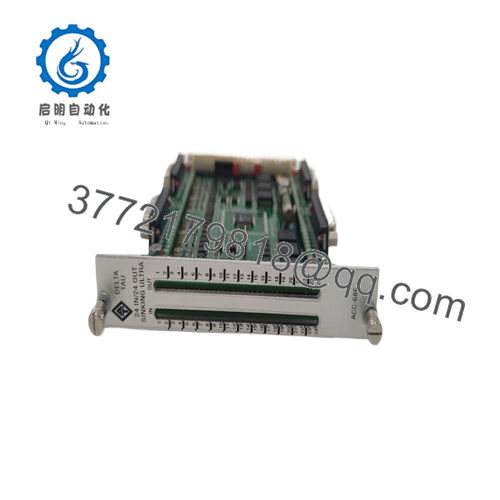

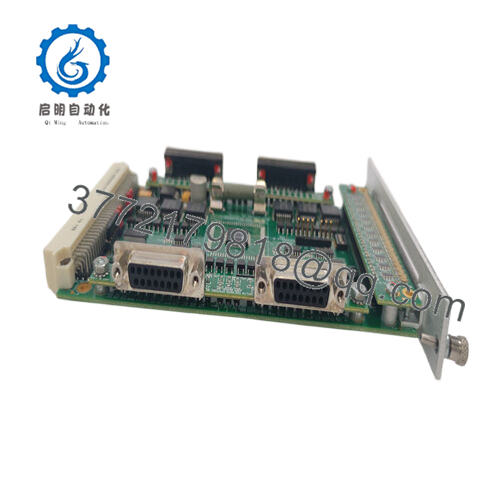

The DELTA TAU ACC-68E functions as an isolated, self-protected digital I/O module, occupying a pivotal position within the automation stack. It interfaces directly with DELTA TAU’s Programmable Multi-Axis Controller (PMAC) backplane, integrating smoothly with the company’s established control platforms. This module is equipped with 24 sinking inputs and 24 sinking outputs, making it suitable for a diverse range of applications. The isolation feature ensures that external electrical noise and voltage spikes don’t disrupt the integrity of the signals, safeguarding the connected equipment from potential damage. Its self-protection mechanism kicks in when abnormal current levels are detected, preventing overloading and short circuits.

ACC-68E

The isolation feature ensures that external electrical noise and voltage spikes don’t disrupt the integrity of the signals, safeguarding the connected equipment from potential damage. Its self-protection mechanism kicks in when abnormal current levels are detected, preventing overloading and short circuits. The module supports standard digital communication protocols, allowing for seamless interaction with other devices in the control system. Unlike generic I/O modules, the DELTA TAU ACC-68E is optimized for use with DELTA TAU’s control systems, eliminating the need for complex and time-consuming custom configurations. This makes the integration process straightforward and efficient, saving valuable engineering resources.

ACC-68E

Technical specifications:

Model Number ACC-68E

Brand DELTA TAU

Type Isolated Digital I/O Module

Input Voltage 12 – 24V DC (self – protected)

Operating Temp Range -10°C to 50°C (14°F to 122°F)

Mounting Style PMAC backplane mounting

Dimensions 180mm x 110mm x 40mm (LxWxH)

Weight 220g

Interface/Bus PMAC backplane (compatible with PMAC2, PMAC Lite)

Compliance CE, RoHS

Supported Protocols Standard digital communication protocols (compatible with DELTA TAU systems)

Typical Power Draw 3W

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

ACC-68E

Main features and advantages:

Engineered with industrial demands in mind, the DELTA TAU ACC-68E offers a plethora of benefits that directly translate into enhanced operational efficiency. Its isolation and self-protection features minimize the risk of equipment damage due to electrical anomalies, reducing maintenance costs associated with repairing or replacing malfunctioning components. The module’s high-quality construction and reliable components are rated for long operational hours, ensuring consistent performance over an extended period. This reliability is further enhanced by the easy integration with DELTA TAU’s control systems, which streamlines the overall setup process. For maintenance teams, the straightforward design of the DELTA TAU ACC-68E simplifies troubleshooting. The module’s status indicators and diagnostic capabilities allow technicians to quickly identify and rectify any issues, minimizing downtime and getting the production line back up and running in no time. Additionally, the module’s ability to handle a significant number of inputs and outputs makes it suitable for large-scale automation projects, where scalability and flexibility are key.

ACC-68E

Application areas:

The DELTA TAU ACC-68E finds extensive use in various industries where precise digital control is essential. In automotive manufacturing plants, it plays a crucial role in controlling the numerous robotic arms and conveyor systems. The module ensures that the signals sent to and from these devices are accurate, preventing any misalignments or collisions that could lead to production errors. In the food and beverage industry, the DELTA TAU ACC-68E is used to control filling and packaging machines. The reliable I/O control provided by the module ensures that the correct amount of product is filled into each container and that the packaging process is carried out smoothly, meeting strict quality standards. In industrial printing applications, the module is responsible for controlling the movement of print heads and the feeding of paper, ensuring high-quality prints with consistent results. Its ability to function reliably in these demanding environments, where continuous operation and precision are non-negotiable, makes the DELTA TAU ACC-68E a top choice for industrial automation professionals.

ACC-68E

Related products:

GE HE693THM666

Triconex 3009

Triconex 3624

Schneider PMC-2/11/04/001/00/03/10/00/10

FIREEYE 95DSS2-1

Tmeic ARND-3110N

smc INR-244-264

GE IC697CPM790

GE IC754VGF15CTD

MacGregor 2141357-804

MacGregor 2141232-802

LAM 839-101612-885

EMC VISATRON VN115/87

Cole Morgan 60WKS-CE240/12PB

TRICONE 3625

TRICONEX 3625

Berger Lahr EXRDM3913/50NEA

TRICONEX 3625

SAACKE HMI10-M REV215

EATON XVS-460-15MP1-1-10

Honeywell HMR2300-D21-485

KONGSBERG RCU502

KONGSBERG RDIOR420

KONGSBERG RSER200-4

KONGSBERG WCC600

GE IS220PDIAH1A

ELAU SM140-30-120-P0-45-M1-B1

GE IS220PDIAH1B

TRICONEX 3625

TRICONEX 3625

Schneider C600/10/1/1/1/00

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONE 3721

TRICONEX 3721

DANIEL DANIEL S600+

schneider XBTGT6340

A-B 1326AB-B720F-21K7-SERIESC

Schneider MICOMP139

PACIFIC SCIENTIFIC BLF2924-10-0-S-017

Rockwell 1794-APBDPV1

Rockwell SST-PB3-SLC

Rusgard LLC GE RS-FS-9001

GE PQMII-C-A

Honeywell IQView8/24

Honeywell IQVIEW4/24

GE F35-W00-VFH-F8L-H6L-M6L-PXX

Yokogawa NFCP100-S05 S3

Woodward 5466-409

TRICONEX 3721

THK TD-020CU-200AC-G15M-5J-N

SIMPLEX 4100-5113

Vibration Monitor AMS3120-A3120/022-000

YOKOGAWA CP451-50S2

HIMA PS1000WR011

YOKOGAWA 3500/22M-01-01-00 288055-01

HONEYWELL FC-SCNT01

Schneider SH30552P11A2000

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626