Description

What This Product Solves

In the precision-driven world of industrial automation, resolving encoder signals with sufficient granularity to achieve sub-micron positioning often exposes the limitations of basic quadrature interfaces, where low-resolution feedback leads to interpolation errors, cumulative drift, and the need for costly mechanical tweaks that disrupt process control flows. Engineers designing multi-axis systems for CNC routers, laser engravers, or coordinate measuring machines grapple with the frustration of noisy sinusoidal inputs—vulnerable to EMI from nearby drives or cabling runs—causing jitter in velocity profiles, overshoot in contouring paths, and false homing triggers that halt spindles mid-cut, inflating cycle times and scrap rates in high-volume runs. Picture a PCB drilling station in electronics fabrication, where encoder ripple misaligns vias by fractions, yielding defective boards that cascade through assembly and test, or a quality inspection arm in automotive parts scanning where position lag erodes tolerance bands, demanding recalibrations that sideline shifts and strain throughput quotas in just-in-time chains.

The Delta Tau ACC-51E addresses these feedback frailties as a dedicated 4096 interpolator accessory card for UMAC systems, engineered to enhance system stability by transforming low-bandwidth sine wave signals into high-resolution digital position data. It focuses on the user’s goal of high reliability in I/O signal processing, accepting inputs from two (or optionally four) sinusoidal encoders to deliver 12-bit interpolated quadrature outputs, filtering noise while preserving phase accuracy for closed-loop corrections that keep axes synchronized within encoder cycles. Essential in modular rack configurations, like expanding Turbo UMAC setups for additional feedback channels or retrofitting legacy motion controllers with finer granularity, this card ensures I/O signal integrity against the electrical turbulence of backplane environments. For searchers targeting “industrial automation encoder interpolators” or “process control UMAC accessories,” the Delta Tau ACC-51E stands as a streamlined enabler, bridging analog encoders to digital precision without the overhead of external ADCs or custom FPGA logic.

By leveraging configurable gain and offset adjustments, it mitigates the engineering toil of signal conditioning, embedding LED diagnostics for quick fault isolation. In process control landscapes where feedback fidelity underpins micron mastery, the Delta Tau ACC-51E reorients from remedial resampling to inherent refinement, fostering the kind of operational acuity that turns potential positioning pitfalls into platforms for unparalleled path adherence and production poise.

How the Product Works & Fits into a System

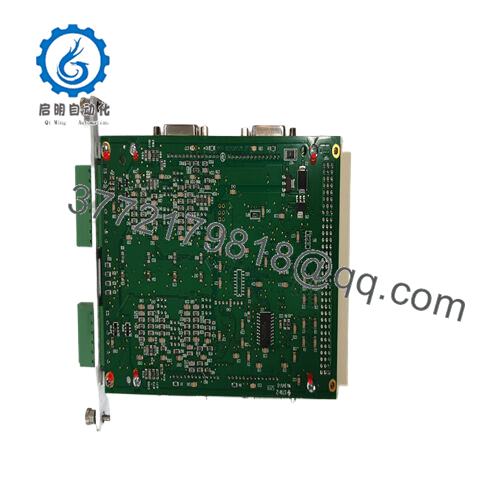

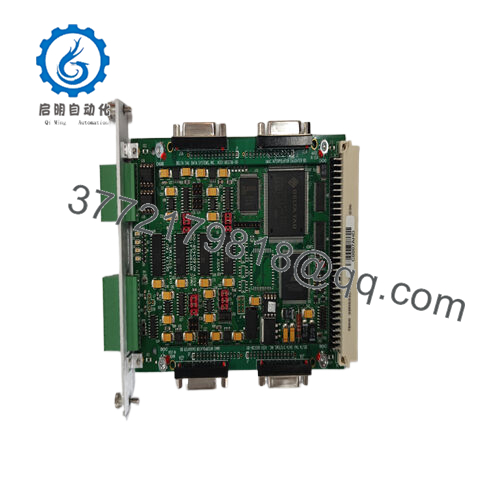

Motion control architectures hum when feedback flows fluidly from encoders to the computational core, but analog sine waves demand deft decoding to unlock their latent detail. The Delta Tau ACC-51E decodes as a 3U Eurocard interpolator, sampling two pairs of differential sine/cosine signals at up to 20 MHz via onboard ADCs, then applying a 4096x interpolation factor through DSP algorithms to extrapolate quadrature pulses—yielding effective resolutions up to 16 bits per revolution—while adjustable threshold comparators clamp noise spikes below 50 mV to avert phantom counts. Configuration options enable four-axis mode via jumper-selectable muxing, routing refined position data to the UMAC host via a dedicated backplane bus for real-time integration into servo loops, complemented by status LEDs that illuminate sync loss or amplitude faults for at-a-glance triage.

Within the broader I/O hierarchy, this card resides at the sensor interface layer, plugging into standard UMAC racks alongside Turbo PMAC CPUs or MACRO modules, where its DB15 connectors mate directly to encoders over twisted-pair cabling shielded against 1 Vp-p common-mode interference. It communicates via the UMAC’s internal memory map, supporting protocols like Delta Tau’s PPMAC scripting for dynamic gain tweaks or fault interrupts that trigger host safeties, ideal for redundant chains where one channel’s dropout reroutes to backups without loop breaks. Diagnostics extend through serial headers for parameter dumps, aligning with SCADA for trend logging of interpolation errors in multi-rack sprawls.

For the integration engineer, it’s intuitively incremental: populate jumpers for voltage scaling (1 Vp-p nominal), seat in an open slot with ESD precautions, then script axis mappings in the PMAC IDE for auto-calibration—deployment distills to under 30 minutes, sidestepping the arcane soldering of discrete interpolators. Position it upstream of the trajectory engine in the stack, where it refines raw encoder chatter into crisp quadrature feeds—like honing laser head coords for burr-free etches. The Delta Tau ACC-51E doesn’t dictate data; it discerns it, nurturing systems that ascend from coarse counts to contiguous contours, where interpolated insight ignites the inference between intent and impeccable execution in the ceaseless cadence of coordinated control.

Technical Highlights Summary (Table)

| Specification | Details |

|---|---|

| Model Number | ACC-51E |

| Brand | Delta Tau (UMAC Series) |

| Type | Encoder Interpolator Accessory |

| Input Voltage | ±15 V (from rack supply) |

| Operating Temp Range | 0°C to +70°C |

| Mounting Style | 3U Eurocard Rack Slot |

| Dimensions | 100 mm x 160 mm (standard 3U) |

| Weight | 0.2 kg |

| Interface/Bus | Backplane Bus / DB15 Connectors |

| Compliance | CE, FCC Class A |

| Supported Protocols | PPMAC Scripting, Quadrature |

| Typical Power Draw | 3 W (from rack) |

Real-World Benefits

Integrating the Delta Tau ACC-51E elevates encoder-derived motion from approximate to absolute, particularly in multi-axis regimes where interpolation depth discerns between drift and definition. Crafted for the grind of high-speed contouring, its 4096x factor distills sine waves into pulse trains that curb cumulative errors to under 1/4096 rev, ensuring performance consistency across 20 MHz samples—vital for plotters where phase skew might mar linework, but here it etches ideals that slash vector variances and reclaim resolution for finer features. This precision propagates to throughput triumphs, enabling tighter servo gains without stability sacrifices, directly inflating feed rates in setups straining for sub-micron sync amid the sim of sim cycles.

The card’s rack-native affinity alleviates assembly anxieties, snapping into UMAC bays with jumper-defined configs that bypass bespoke breakout boards, lightening engineering loads in expansions where channel creep demands swift scalability—crews repurpose shifts for sim-tuned filters that finesse noise floors. Maintenance matures into minimalism, with LED beacons and scriptable diagnostics beaming amplitude alerts to HMIs for preemptive tweaks, extending probe cadences to quarterly quiets and empowering remote re-gains that nix 80% of field faults, diverting deftness to deltas like adaptive thresholding for evolving encoder ages.

Over operational orbits, the Delta Tau ACC-51E vows vigilance via ruggedized ADCs that defy 10^9 counts in vibrational vigils, twinned with the 3 W thrift that slims thermal footprints in dense Eurocard arrays, easing enclosure economics in scaled sims. Engineered to outrun obsolescence, it curtails the churn of channel chasms, granting the grace to graft adjuncts—from quadrature quadrature to quad-axis quorums—actualizing as the keystone that crystallizes counts into clarity, where interpolated integrity ignites the impetus for impeccable industrial ingenuity in the forge of fastidious feedback.

- ACC-51E

Typical Use Cases

The Delta Tau ACC-51E refines resolution in realms of rigor and rapidity, commencing with precision machining for multi-tool CNC mills that carve aerospace brackets. In process control environments laced with coolant aerosols and spindle songs, it interpolates sinusoidal feedback from linear scales at 4096x to lock axes within microns, where harsh vibrational veils from fly-cutting buffet boards but bolster critical system uptime—bedrock for cycles milling 1,000 parts per shift, forestalling arc errors that could compromise airframe fits. Fast data cycles conjugate with UMAC kernels for spline-traced pockets that sustain surface specs sans sim stutters.

In semiconductor metrology, the Delta Tau ACC-51E decodes stage encoders amid ESD halos and vacuum whirs, upscaling quasi-sine inputs for probe placements with 16-bit poise. Continuous uptime underpins fab flows, as its noise clamps preempt phantom steps in wafer walkers, meshing with PPMAC for sub-nm scans that dodge defect drifts. Performance pinnacles in dust-free drifts, yet it upholds I/O signal sanctity, mitigating re-maps in yield-questing quests.

For additive manufacturing, used in power plants for turbine blade scanners or afar—the Delta Tau ACC-51E hones gantry encoders in laser sintering beds, braving powder puffs and beam glare to layer contours. Harsh thermal throbs from melt pools test its tenacity, fusing with motion scripts for voxel fidelity that meets alloy quals. Traversing machining’s mill, semi’s scan, and add-man’s alloy—the Delta Tau ACC-51E fuses high reliability with refined reckoning, sustaining sectors where interpolated insight illuminates impeccable iteration.

Compatible or Alternative Products

ACC-51E Option 2 – Four-axis configuration for expanded feedback in multi-spindle setups.

ACC-8E – Digital I/O companion for signal conditioning in UMAC hybrid expansions.

ACC-24E2 – Analog interface module for voltage/current bridging in sensor-dense nodes.

ACC-59E3 – 16-bit A/D-D/A card for high-res analog in Power PMAC transitions.

PMAC2-EC – UMAC CPU upgrade for enhanced processing in interpolator-heavy racks.

ACC-72E – Digital I/O expander for fault-tolerant I/O in redundant loops.

Turbo PMAC2-3U – Rack-compatible host for seamless ACC-51E integration in legacy sims.

NI-6602 – National Instruments alternative for LabVIEW-tied quadrature timing.

Setup Notes & Maintenance Insights

As you slot the Delta Tau ACC-51E into your UMAC rack, a compatibility cull clears config clouds: affirm the host’s firmware via PPMAC query for v3.0+ to unlock 4096x modes, as lags limit to 1024x—flash if firmware falters. Slot seating calls for ESD straps and a pin continuity zap with a multimeter on the backplane fingers; bent leads from prior pops breed bit flips, so realign with a soft pick and latch the ejectors evenly to evade vibration voids. Jumper jazz for axis count (2/4) and gain (x1-x10) demands a sim run—wire a 1 Vp-p test tone to channel 1, then scope the output for 4096 pulses/rev, tweaking offsets if phase skews >5°. Thermal trace in env models: mimic rack flow at 0.2 m/s to vet 70°C poise, baffling if clustered with power-hungry PMACs in sims that sim surge.

Perpetuating the Delta Tau ACC-51E courts calibration over crisis. Bi-weekly, eye the LEDs for amplitude blinks—dim reds cue sine sag, sim’d with a function gen to confirm >0.8 Vp-p peaks. Quarterly, reseat DB15s in low-static lulls to thwart connector creep; a loupe spots corrosion, but a contact cleaner spritz restores without residue riots. Annual accuracy audit—cycling a precision encoder in closed loop—benchmarks against 1/4096 rev error; drifts past 0.1% intimate ADC drift, reset via host script or swap the card for a calibrated clone. Firmware fusion with the UMAC averts axis anarchy; infuse during sim-only sims, verifying via quadrature count in jog mode. These prudent paces, pulled from PMAC playbooks, prolong the interpolator’s 20 MHz mettle, funneling finesse to fine-tunes from fault-finding frays.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626