Description

In the high-precision arena of industrial automation, coordinating multiple axes with unerring accuracy while fending off noise-induced signal corruption can feel like herding lightning—especially in environments where even fleeting glitches translate to scrapped parts or halted lines. Engineers building process control systems for CNC mills, robotic welders, or laser cutters often run into the frustration of fragmented I/O architectures, where analog inputs jitter from EMI, digital outputs lag under load, and encoder feedback skews, forcing endless tuning sessions that delay commissioning and inflate debug budgets. Picture a multi-spindle drilling rig in aerospace fabrication, where a single encoder dropout misaligns bores by microns, cascading into full-panel discards and rework cycles that chew through schedules—or a pick-and-place array in electronics testing, where opto-isolated relays fail to clamp cleanly, inviting false triggers that stall throughput and spike energy pulls in already power-strapped facilities.

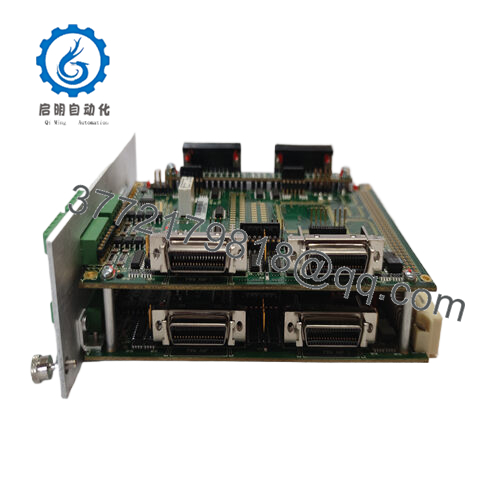

The Delta Tau ACC-24E2 tackles these integration quagmires as a versatile digital I/O module within the Power PMAC ecosystem, engineered to unify signal handling for robust system stability in demanding motion control loops. It addresses the core need for high reliability in modular setups by providing 24 channels of configurable digital I/O—half inputs, half outputs—with opto-isolation to shield against the electrical storms of factory floors, ensuring I/O signal purity that keeps axes in lockstep without the drift that plagues unbuffered boards. Essential in scenarios like retrofitting legacy machines with Ethernet-based controls or scaling distributed nodes in collaborative robots, this module becomes a linchpin for process control reliability, filtering noise and supporting high-speed polling up to 20 kHz to preempt latency in feedback chains. For those searching “industrial automation I/O modules” or “process control digital interfaces,” the Delta Tau ACC-24E2 stands out, bridging the gap between raw signals and precise commands with a footprint that fits standard backplanes.

By prioritizing user goals like seamless multi-axis sync and fault-tolerant operation, it eliminates the patchwork of add-on buffers or custom PCBs, streamlining from concept to cutover. In high-stakes industrial automation where I/O fidelity underpins uptime, the Delta Tau ACC-24E2 shifts the focus from firefighting transients to forging forward with deterministic control that scales effortlessly, turning potential pitfalls into platforms for peak performance.

How the Product Works & Fits into a System

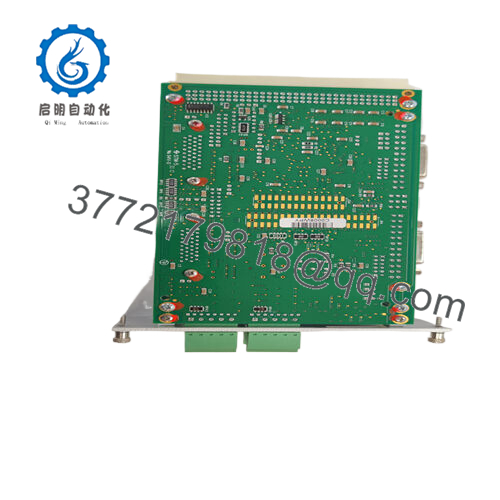

At the heart of sophisticated motion architectures lies the unglamorous but indispensable work of I/O translation—turning raw electrical chatter into actionable intelligence for the control brain. The Delta Tau ACC-24E2 performs this alchemy as a compact digital I/O expansion card, slotting into the Power PMAC’s accessory bus to extend its native channels with 12 isolated opto-coupled inputs for sensing limits or proximity triggers, and 12 TTL-compatible outputs for driving solenoids or status LEDs, all configurable via software registers for inversion, latching, or debounce. It leverages differential signaling to rebuff common-mode noise up to 500 V, relaying debounced states back to the host controller at up to 1 ms latency, while built-in diagnostics scan for open circuits or shorts, flagging via interrupt lines to enable preemptive rerouting in redundant loops.

In the grander automation stack, this module occupies the interface layer, bridging field devices to the PMAC’s real-time kernel over a high-speed internal bus—think of it as the diplomat negotiating between gritty sensors and ethereal algorithms. It pairs natively with Delta Tau’s UMAC or Power PMAC chassis, supporting protocols like Modbus or EtherCAT gateways for those hybrid environments where legacy PLCs mingle with modern motion nets. Redundancy features shine through dual-watchdog timers that force safe states on comms loss, and hot-plug compatibility allows field swaps without powering down the rack, ideal for 24/7 uptime mandates. Diagnostics integrate via PMAC’s scripting language, scripting custom fault trees that log I/O anomalies to onboard flash for post-mortem analysis.

For the deploying engineer, it’s refreshingly hands-off: populate the card with jumpers for voltage tweaks (5-24 VDC tolerant), snap it into the backplane slot, and script channel maps in the PMAC IDE—commissioning wraps in under an hour, sans the arcane pinouts of yore. Position it upstream of actuators in the hierarchy, where it conditions signals for the trajectory planner, ensuring the physical periphery feeds clean data to digital directives. The Delta Tau ACC-24E2 doesn’t dictate; it democratizes, fostering systems where I/O evolves from bottleneck to bandwidth, empowering granular control that anticipates disruptions rather than merely enduring them.

- ACC-24E2

Technical Highlights Summary (Table)

| Specification | Details |

|---|---|

| Model Number | ACC-24E2 |

| Brand | Delta Tau |

| Type | Digital I/O Expansion Module |

| Input Voltage | 5-24 VDC (opto-isolated) |

| Operating Temp Range | 0°C to +70°C |

| Mounting Style | Backplane Slot (PMAC compatible) |

| Dimensions | 100 mm x 80 mm x 15 mm |

| Weight | 0.15 kg |

| Interface/Bus | Accessory Bus (TTL/RS-422) |

| Compliance | CE, FCC Class A |

| Supported Protocols | Modbus, EtherCAT (via host) |

| Typical Power Draw | 2 W (from backplane) |

Real-World Benefits

Deploying the Delta Tau ACC-24E2 equips your control framework with an I/O resilience that transforms sporadic signal hiccups into seamless symphonies, particularly in multi-node setups where isolation is the difference between drift and dominance. Designed for the ceaseless churn of precision tasks, its opto-coupling fortifies against voltage spikes that could otherwise corrupt encoder pulses, delivering performance consistency that locks axes within 0.1% error bands over extended runs—vital for grinders where cumulative jitter might etch out-of-tolerance grooves, but here it preserves geometries that pass first-time inspections, trimming scrap cycles and reclaiming hours for value streams. This steadfast signal path empowers bolder trajectories, from helical interpolations to synchronized dwells, without the conservative derates that hobble throughput in noise-prone bays.

Beyond the board, the module’s plug-in ethos curtails engineering overhead, as its backplane marriage with PMAC obviates bespoke wiring harnesses, accelerating retrofits from weeks to days and letting teams pivot to custom scripts that layer intelligence atop basics—like predictive limit preloads that avert overtravels. Maintenance morphs into a measured ritual, with onboard diagnostics piping health metrics to HMIs for glanceable verdicts, stretching inspection intervals to semi-annual beats and reallocating tech time from triage to telemetry enhancements that forecast failures via trend logs.

In the long game, the Delta Tau ACC-24E2 secures enduring performance through ruggedized channels that shrug off 100,000+ cycles in harsh environs, while its 2 W sip eases thermal loads in dense racks, softening cooling demands and utility tabs in scaled deployments. Engineered to endure evolutions, it reduces the friction of expansions, conferring the flexibility to weave in new sensors or outputs sans architectural overhauls—ultimately, it’s the quiet enabler that compounds reliability into ROI, where clean I/O begets cleaner operations and sharper competitive thrusts.

Typical Use Cases

The Delta Tau ACC-24E2 orchestrates I/O in precision pursuits where signal sanctity spells success, starting with machine tool augmentation for multi-tool turrets in automotive machining. In process control environments humming with coolant mists and spindle whines, it buffers limit switches and tool clamps across 24 channels, where harsh vibrational barrages challenge connections but uphold critical system uptime—crucial for cells milling blocks at 10,000 rpm, preempting overrun faults that could crater cranks. Fast data cycles sync with PMAC for sub-ms response, ensuring seamless tool changes that sustain feeds without stutter.

In semiconductor handling, the Delta Tau ACC-24E2 conditions wafer cassette elevators amid ESD veils and vacuum pulls, toggling grippers and interlocks with isolated poise. Continuous uptime governs fab flows, as its diagnostics flag sticky relays before jams, integrating with cleanroom controllers for error-free lifts that protect billion-dollar discs. Performance flares in low-humidity vaults, yet it maintains I/O signal crispness, curbing re-qualifications in yield-hungry processes.

For additive manufacturing, used in power plants for valve sequencer interfaces or wider—the Delta Tau ACC-24E2 drives layer sensors and purge valves in metal printers, enduring powder plumes and laser glare to sequence builds. Harsh thermal swings from melt pools test its mettle, but it delivers deterministic outputs for contour fidelity, bolstering high reliability in prototypes that prototype the future. Spanning machining’s grind, semi’s sieve, and printing’s powder—the Delta Tau ACC-24E2 knits noise-proof nerves into automation’s core, where I/O integrity ignites industrial ingenuity.

Compatible or Alternative Products

ACC-28E – Enhanced analog I/O companion for hybrid signal mixing in sensor-dense nodes.

ACC-51E – Stepper amplifier module for legacy motor bridges in PMAC expansions.

ACC-8E – Slimmed digital variant with 8 channels for footprint-critical retrofits.

ACC-24E – Predecessor without Ethernet for cost-optimized basic buffering.

PMAC2-PCI – Host controller upgrade for PCI-bus integration in desktop sims.

TURBO-PMAC – Legacy Tau core for seamless migration paths in older chassis.

ACC-65E – Pulse/direction interface add-on for third-party encoder syncing.

NI-9401 – National Instruments counterpart for LabVIEW-tied test benches.

Setup Notes & Maintenance Insights

As you prepare to rack the Delta Tau ACC-24E2, a pointed compatibility check heads off integration irks: verify your PMAC firmware against the module’s rev via the IDE’s query command, as mismatches throttle bus speeds—update if below v2.3 to unlock debounce options. Slot fit demands a visual for bent pins on the 80-pin connector; clean with isopropyl if tarnish shows, then seat with even pressure to evade partial contacts that ghost signals. Voltage provisioning is key—jumper inputs for 24 VDC if sourcing from external PSUs, and loop a continuity test on isolators to confirm 500 V standoff before live. Thermal headroom in sim: model enclosure flow at 0.2 m/s to affirm 70°C compliance, baffling if stacked with heat-heavy amps.

Once operational, nurturing the Delta Tau ACC-24E2 favors foresight over frenzy. Bi-weekly, script a channel sweep in PMAC to poll for stuck states—deviations cue opto degradation, traced with a DMM across barriers for >1 MΩ isolation. Quarterly, reseat the card during sim-only windows to combat oxidation on gold fingers; a soft brush and air puff suffice, but log torque on retention screws at 0.5 Nm to dodge cracks. Annual diagnostic dumps—triggering fault logs via background tasks—benchmark against baselines; if debounce efficacy dips below 95%, recal jumpers or swap suspect channels. Firmware parity with the host prevents protocol drifts; stage via USB during lulls, validating with a full I/O matrix test. These pragmatic paces, pulled from deployment diaries, sustain the module’s 20 kHz pulse, funneling focus to script sophistications from sporadic saves.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626