Description

The DDC4-10-40020 functions as a compact, high-performance controller that sits at the intersection of field devices and central control systems. It acts as a translator and processor, receiving analog and digital signals from sensors, actuators, and other field equipment, then converting and transmitting that data to higher-level control platforms with minimal delay. What sets it apart is its seamless integration with both traditional backplane systems and modern Ethernet-based architectures, making it a versatile choice for retrofits and new installations alike.

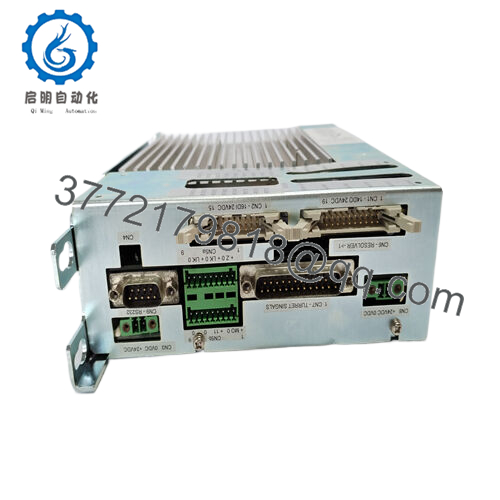

DDC4-10-40020

DDC4-10-40020

Technical specifications:

Model Number DDC4-10-40020

Type Distributed Control Controller

Input Voltage 24V DC

Operating Temp Range -40°C to 70°C

Mounting Style DIN rail

Dimensions 120mm x 85mm x 60mm

Weight 320g

Interface/Bus Modbus RTU, Ethernet/IP

Compliance CE, RoHS, UL 508

Supported Protocols Modbus TCP, Profibus DP, BACnet

Typical Power Draw 5W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

DDC4-10-40020

Main features and advantages:

Choosing the DDC4-10-40020 means investing in a controller that’s engineered for long-term performance in the most demanding industrial settings. Its robust design, with a ruggedized casing and wide operating temperature range, ensures it thrives in environments with extreme heat, humidity, or vibration—conditions that would degrade lesser components. This durability translates to fewer replacements and repairs, reducing maintenance costs over the product’s lifespan. Engineers will also appreciate the time saved during integration: the controller’s plug-and-play functionality, combined with its broad protocol support, minimizes the need for custom programming or workarounds when connecting to existing systems. Perhaps most importantly, the DDC4-10-40020 delivers consistent performance, with signal processing that remains stable even under heavy load. This consistency means more accurate process control, fewer production variances, and ultimately, higher product quality.

DDC4-10-40020

Application areas:

In practice, the DDC4-10-40020 proves its worth across multiple industries. In water and wastewater treatment plants, it’s used to monitor and control pump stations and chemical dosing systems, where precise flow rate management and reliable communication with SCADA systems are critical for regulatory compliance. In automotive manufacturing, the controller integrates with robotic arms and conveyor systems, ensuring synchronized movement and real-time feedback to maintain production line efficiency. It also excels in food and beverage processing, where its resistance to dust and moisture helps it operate reliably in clean-in-place (CIP) environments. In each of these settings, the DDC4-10-40020 meets the demand for continuous uptime, withstanding the rigorous cycles of 24/7 operation that are standard in process control environments.

DDC4-10-40020

Related products:

Other product models:

REXROTH 4DMC160

GE 350-E-P1-G1-H-E-S-C-P-SN-D-N

Woodward 9907-135

ABB 216EA62

Emerson NTM-212-CBNS-0000

PROSOFT 5302-MBP-MCM4

AMAT SD1024F-2-S

KONGSBERG AKM32S-ASSNS-05

ABB 216EA62

ABB 216EA62

ABB 216EA62 1MRB150083R1/F

Emerson A6370D

DEIF PPU/2/GS

DELEM DM-103VA

ABB 216MB66 HESG324510M1

ABB 216NG62A HESG441634R1/K HESG216876

ABB 216NG63A HESG441635R1 HESG216879/K

ABB 216V62a HESG324442R13/B

ABB 216VC62a HESG324442R112/F

Baikale 8MSA3X.R0-30

WOODWARD 9907-014

WOODWARD 8440-2165

B&R 8MSA3X.R0-30

Emerson CE3007

ABB 216VC62a HESG324442R112/F

REXROTH HDS02.2-W040N-HS32-01-FW

Eaton XV-230-57CNN-1-13-1

WOODWARD 8405-094

ABB 216VC62a HESG324442R112/F

WOODWARD SPM-D2-10 8440-2066A

Eaton XV-440-10TVB-1-50

OMNI 6000-1D-1SE-1A-2SV

ABB 216VC62a HESG324442R13/B

ABB 216VC62A HESG324442R112/F

NI SBRIO-9627

Renishaw RLU10-A3-A3

BENTLY 3500/65-01-00 145988-02

WARNER MCS2000-ECA

WARNER MCS2000-DRV2

MECS CS-1000A

A-B 80026-529-01-R

ABB 216VC62A HESG324442R13

GE 5266222-2 – GSCB GOC6.6

LAM 810-135227-010

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626