Description

Real-World Use & Application Scenarios

In the precise world of automated material handling, where a conveyor system must synchronize the movement of packages with a robotic palletizer, or in a textile factory where multiple rollers need to maintain exact speed relationships under varying loads, the demand for synchronized motion is non-negotiable. These applications rely on a digital command signal that dictates the pace and position for an entire section of machinery. The DCF804-0050 is the critical interface that makes this synchronization possible. This device is deployed as a central component in multi-drive systems, commonly found in printing presses, packaging lines, and assembly stations. It takes a high-speed reference signal—often a pulse train representing a master speed or position—and distributes it accurately to one or more inverter or servo drives. By ensuring that every connected drive receives a perfectly timed command, the DCF804-0050 eliminates the cumulative errors that cause products to jam, processes to fall out of sync, and overall equipment effectiveness to plummet. Its role is to be the unerring conductor in an orchestra of motors, ensuring harmonious and efficient operation.

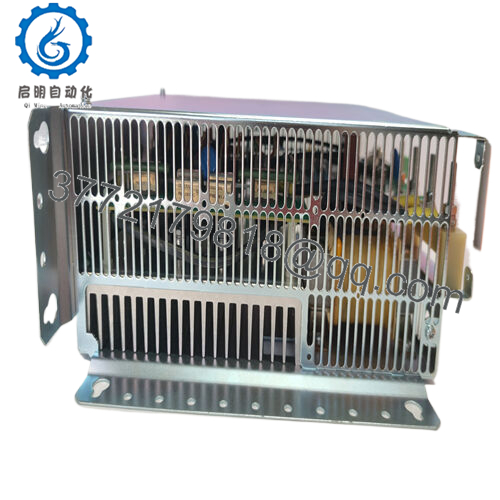

Product Introduction & Positioning

The DCF804-0050 is a specialized frequency converter interface module, specifically designed to expand the capabilities of a master drive within the Danfoss VACON® NXP system. It functions as a high-speed I/O and communication gateway, enabling the drive to interact with a wider ecosystem of control components. Rather than acting as a standalone drive, this module slots directly into the drive’s modular control unit, giving it the ability to receive direct pulse encoder feedback or high-speed analog references. For machine builders and control system designers, the value of the DCF804-0050 lies in its ability to unlock advanced motion control functionalities. It transforms a standard variable speed drive into a tightly integrated follower or a precise positioning unit, bridging the gap between basic speed control and sophisticated, coordinated motion without necessitating a full-scale motion controller. This provides a cost-effective path to enhanced performance and flexibility.

Key Technical Features & Functional Benefits

The DCF804-0050 excels in its high-fidelity signal processing and robust integration. A core strength is its high-speed encoder interface, which can accept signals from a wide range of incremental encoders. This allows the host drive to perform precise speed or position control based on direct feedback from a master axis or a measuring wheel, enabling true electronic line shafting applications. The module’s circuitry is designed for the electrically noisy environment of an industrial control cabinet, with robust filtering and isolation to ensure signal integrity and prevent false counts or data corruption that would disrupt the entire process.

From a system integration perspective, the module’s plug-and-play design with the VACON NXP platform is a significant advantage. It eliminates the need for external signal conditioners and complex wiring, reducing points of failure and saving valuable panel space. The module is fully recognized and configured through the standard drive software, providing a unified interface for setting up all parameters, from encoder line count to signal filtering. This seamless integration, combined with its support for key safety standards, makes the DCF804-0050 a reliable and straightforward solution for adding sophisticated follower and synchronization capabilities to a robust drive platform.

- DCF804-0050

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | DCF804-0050 |

| Brand | Danfoss |

| Type | Encoder & Frequency Reference Interface Module |

| Power Supply | 24 V DC (via drive control unit) |

| Operating Temperature | 0 to 55 °C (32 to 131 °F) |

| Mounting | Plug-in module for VACON NXP Control Unit |

| Dimensions | Standard module form factor |

| Weight | Approx. 0.2 kg |

| Encoder Input | Differential (RS422) or single-ended, up to 5 MHz |

| Analog Inputs | 2 x ±10 V DC, 16-bit resolution |

| Digital I/O | 4 programmable digital inputs |

| Certifications | CE, cULus, DNV GL |

| Isolation | 500 V AC (Encoder and analog inputs) |

Related Modules or Compatible Units

VACON NXP Liquid Cooled – A high-power drive unit that can be equipped with the DCF804-0050 for demanding pump and fan synchronization.

VACON NXP Air Cooled – The standard drive platform that hosts this interface module in most industrial applications.

DCF803-0050 – A communication module option for adding PROFIBUS DP connectivity to the same drive.

DCO804-0010 – An optional safety module that can be combined with the DCF804-0050 for integrated safe torque off (STO) functionality.

MBS3000 – A Danfoss magnetostrictive displacement sensor that can provide precise feedback for positioning applications.

Installation Notes & Maintenance Best Practices

Correct installation begins with ensuring the VACON NXP drive is completely powered down and isolated from all power sources, including the DC bus, before attempting to install the DCF804-0050 module. The module should be firmly seated in its designated slot in the control unit, ensuring the connector is fully engaged. For the encoder and signal wiring, it is imperative to use shielded, twisted-pair cables. The cable shield should be grounded at the drive end only, typically using the designated functional earth terminal, to create a clean drain path for electrical noise without creating ground loops. Maintain as much physical separation as possible between these sensitive signal cables and high-power motor leads or AC supply lines to prevent inductive coupling and signal interference.

Maintenance for the DCF804-0050 is primarily diagnostic and preventative. The module’s status is continuously monitored by the main drive processor, and any communication faults or signal errors are reported through the drive’s display and diagnostic logs. Periodically inspect the module and its connections for any signs of physical damage or corrosion. The most effective maintenance practice is to regularly monitor the signal quality and error counters available in the drive’s parameter list, which can provide early warning of a degrading encoder or wiring issue. Ensure that the drive’s firmware, which also governs the module’s operation, is kept up to date with the latest stable release from Danfoss.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626