Description

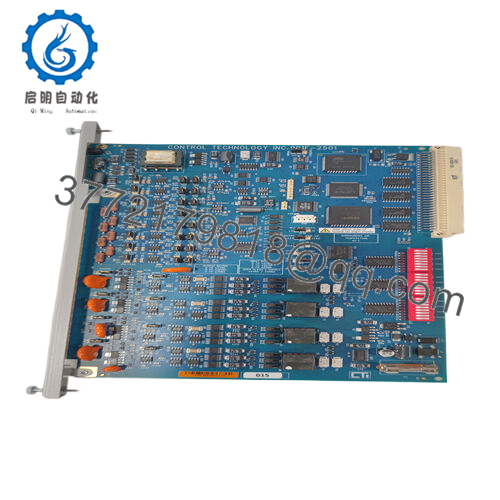

CTI -2501 is a powerful analog input/output module designed specifically for industrial automation systems, aimed at achieving efficient conversion and reliable transmission between analog and digital signals. It adopts a compact single width module design, which can easily adapt to the 2500 series I/O base, providing convenience for system integration.

CTI-2501

From the perspective of system interaction, the CTI -2501 has 8 analog input channels and 4 analog output channels. Analog input channels support a variety of common signal types, including 0-5V, 0-10V, 0-20mA, 4-20mA, and each channel can independently select unipolar or bipolar input modes, which can meet the signal access needs of different sensors. The analog output channel also supports multiple signal types, and can simultaneously output voltage and current signals. The output range is flexible and adjustable, and can accurately drive various actuators. This module has a fast update time of 6 milliseconds, and all channels can complete signal acquisition and output updates in a short period of time, meeting the high real-time requirements of industrial application scenarios. CTI -2501 supports optional operation modes of input/output or input only, and users can flexibly configure module functions according to actual application needs. In terms of signal isolation, 1500V electrical isolation is achieved between the input and output channels and the PLC backplane, and 1500V isolation is also achieved between the output channels, effectively preventing signal interference and the propagation of electrical faults, and improving the stability and reliability of the system. In addition, the module also supports Modbus RTU communication protocol, which enables seamless communication with other industrial devices and facilitates the construction of complex automation control systems.

CTI-2501

Technical specifications:

Model CTI -2501

Type Analog Input/Output Module

Number of analog input channels 8

Analog input signal range: 0-5V, 0-10V, 0-20mA, 4-20mA, unipolar or bipolar optional

Number of analog output channels 4

The analog output signal range can simultaneously output voltage and current signals, such as 0-10V, etc

Update time 6 milliseconds

Operation mode input/output or input only optional

Channel isolation input and output are isolated from the PLC backplane by 1500V, and output channels are isolated by 1500V

Communication Protocol Modbus RTU

Maximum power consumption of 15W

Working temperature range -20 ° C to+85 ° C

Working humidity range of 5% to 95%, no condensation

Dimensions (width x height x depth) 114mm x 114mm x 100mm

Connection method terminal block

Certification CE, UL

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

CTI-2501

Main features and advantages:

CTI -2501 has demonstrated many significant advantages in practical applications. Its rich analog input and output channels, as well as flexible signal type selection, enable it to adapt to various complex industrial application scenarios without the need for additional signal conversion equipment, reducing system costs and complexity. The fast update time ensures that the system can respond to external signal changes in a timely manner, achieve real-time and precise control of the production process, and effectively improve production efficiency and product quality. For example, in high-speed filling production lines, CTI -2501 can quickly collect liquid level sensor signals and control the opening of filling valves in a timely manner, ensuring the accuracy and consistency of filling volume. The powerful signal isolation function greatly enhances the anti-interference ability of the system. In industrial sites with complex electromagnetic environments, it can operate stably and reliably, reducing equipment failures and production interruptions caused by signal interference, and improving the stability and reliability of the system.

CTI-2501

Application areas:

The application scope of CTI -2501 is very wide. In the manufacturing industry, equipment control and monitoring commonly used in automated production lines, such as tool status monitoring during machine tool processing, robot motion control, etc; In the process control industry, it can be applied to production process control in chemical, power, metallurgy and other fields, such as temperature and pressure control of chemical reaction vessels, voltage and current monitoring and regulation of power systems, etc; In terms of building automation, it can be used for environmental monitoring and equipment control in intelligent buildings, such as energy-saving control of central air conditioning systems and brightness adjustment of intelligent lighting systems.

Related products:

CTI 2502: On the basis of CTI 2501, some special functions have been added, such as higher precision analog input channels, which are suitable for controlling scientific research experimental equipment with extremely high requirements for signal acquisition accuracy.

CTI -2500: With a small number of channels, it has 4 analog input channels and 2 analog output channels, making it suitable for small automation systems or cost sensitive application scenarios.

CTI 2511: It has stronger anti-interference ability and adopts special shielding materials and circuit design, suitable for industrial environments with extremely severe electromagnetic interference, such as high-frequency welding workshops.

CTI -2501E: Enhanced version, expands the working temperature range to -40 ° C to+100 ° C, and can work stably in extreme temperature environments, such as outdoor industrial equipment monitoring, high-temperature furnace control, and other scenarios.

CTI -2501P: Supports Profibus DP communication protocol, suitable for industrial automation systems that have already established Profibus DP networks, facilitating communication and integration with other devices that support this protocol.

CTI -2501S: With a higher protection level (IP65), it is dustproof and waterproof, suitable for harsh industrial environments such as mining and sewage treatment plants.

CTI -2501M: Equipped with built-in data storage function, it can record analog signal data for a certain period of time, facilitating subsequent analysis and traceability. It is suitable for quality inspection, equipment fault diagnosis and other application scenarios that require data recording.

Installation and maintenance:

Before installing CTI -2501, it is necessary to carefully check the installation environment. Ensure that the slots of the 2500 series I/O dock are intact and fully compatible with the interface of the CTI -2501. Check whether the power supply is stable, whether the voltage is within the range required by the module, and ensure that the power capacity can meet the normal operation of the module and the possible peak current demand. When connecting signal cables, they should be connected correctly according to the wiring diagram to ensure that the cables are firm and reliable, and to avoid loosening or poor contact that may cause abnormal signal transmission. In addition, it is necessary to plan the communication lines in advance to ensure smooth Modbus RTU communication connections with other devices and avoid signal interference.

During the daily maintenance of the equipment, the status indicator lights on the module should be regularly observed. Under normal circumstances, the indicator light should display a constant green light. If the indicator light flashes or turns red, it indicates that the module may have a fault and detailed fault information needs to be read immediately through the communication interface or other diagnostic tools. Conduct a comprehensive parameter check on the module once a month, comparing the simulated signal values collected and output with the theoretical values to ensure the accuracy of the signals. Clean the dust on the surface and interface of the module once a quarter to prevent poor heat dissipation or poor contact caused by dust accumulation. Conduct in-depth testing on the module once a year, including simulating various abnormal input signals, verifying the signal processing capability and fault protection mechanism of the module, and updating the firmware version of the module to obtain the latest functionality and performance optimization.

Other product models:

REXROTH 4DMC160

GE 350-E-P1-G1-H-E-S-C-P-SN-D-N

Woodward 9907-135

ABB 216EA62

Emerson NTM-212-CBNS-0000

PROSOFT 5302-MBP-MCM4

AMAT SD1024F-2-S

KONGSBERG AKM32S-ASSNS-05

ABB 216EA62

ABB 216EA62

ABB 216EA62 1MRB150083R1/F

Emerson A6370D

DEIF PPU/2/GS

DELEM DM-103VA

ABB 216MB66 HESG324510M1

ABB 216NG62A HESG441634R1/K HESG216876

ABB 216NG63A HESG441635R1 HESG216879/K

ABB 216V62a HESG324442R13/B

ABB 216VC62a HESG324442R112/F

Baikale 8MSA3X.R0-30

WOODWARD 9907-014

WOODWARD 8440-2165

B&R 8MSA3X.R0-30

Emerson CE3007

ABB 216VC62a HESG324442R112/F

REXROTH HDS02.2-W040N-HS32-01-FW

Eaton XV-230-57CNN-1-13-1

WOODWARD 8405-094

ABB 216VC62a HESG324442R112/F

WOODWARD SPM-D2-10 8440-2066A

Eaton XV-440-10TVB-1-50

OMNI 6000-1D-1SE-1A-2SV

ABB 216VC62a HESG324442R13/B

ABB 216VC62A HESG324442R112/F

NI SBRIO-9627

Renishaw RLU10-A3-A3

BENTLY 3500/65-01-00 145988-02

WARNER MCS2000-ECA

WARNER MCS2000-DRV2

MECS CS-1000A

A-B 80026-529-01-R

ABB 216VC62A HESG324442R13

GE 5266222-2 – GSCB GOC6.6

LAM 810-135227-010

LAM 810-240888-002

LAM 810-107813-306

yokogawa ALP111-S001

Eaton XVH-340-57CAN-1-50

ABB 216VC62A HESG324442R13

Emerson A6125 9199-00069

Emerson A6210 9199-00003

ABB 216VC62A HESG324442R13

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626