Description

In the demanding world of industrial automation, where process control systems must process a blend of analog signals from sensors and transducers without succumbing to noise, scaling errors, or integration bottlenecks, the real hurdle often lies in maintaining signal accuracy amid varying field conditions that could skew measurements and disrupt closed-loop operations. Consider a wastewater treatment facility or a manufacturing line for batch mixing: pressure gauges and level transmitters feed continuous analog data into PLC loops for proportional control, but voltage drops over long runs, ground potentials, or sensor nonlinearities distort those inputs, leading to imprecise dosing, pump overruns, or compliance gaps under standards like IEC 61131 for high-reliability environments. Traditional I/O modules might handle discrete points adequately, but they strain under mixed loads, lacking the density, configurability, and diagnostic transparency needed for modular PLC architectures where seamless replacement of legacy components is key to minimizing downtime and preserving wiring investments in setups prone to thermal shifts or EMI from adjacent motors.

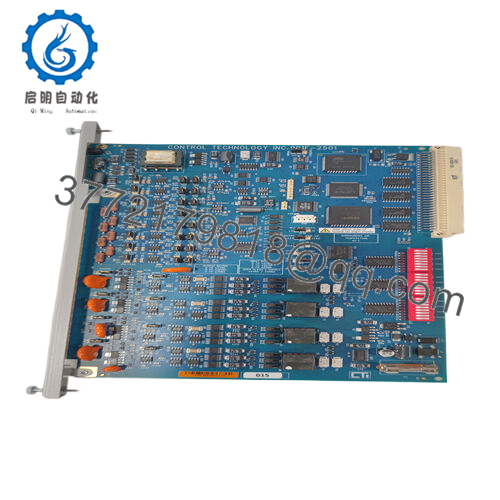

The CTI -2501 enters as a versatile 8-input/4-output analog module from Control Technology Inc.’s 2500 Series, designed precisely to fortify hybrid signal handling in these legacy-compatible control systems. This unit confronts the need for system stability by acquiring 8 differential analog inputs (voltage or current) with 12-bit resolution and outputting 4 isolated analog signals for actuators, all while providing per-channel scaling and broken-wire detection to preempt failures. In typical industrial automation scenarios—such as analog monitoring for flow regulation in HVAC skids or level control in tank farms—the CTI -2501 becomes a linchpin, enabling drop-in compatibility with existing Simatic 505 bases that draw 5 VDC from the backplane without rewiring, ensuring I/O signals from 4-20 mA transmitters or 0-10 V transducers remain faithful even through 100 m cables. Its mixed configuration balances input-heavy sensing with output-driven actuation, ideal for retrofits where space constraints and budget limits demand multifunctional hardware that upholds process continuity without full-system overhauls.

For teams migrating from Siemens 505-7012/7016 modules, the CTI -2501 simplifies the transition with identical pinouts and firmware mapping, cutting commissioning time while embedding diagnostics that flag out-of-range values via status bits to the PLC. In high-reliability process control, it shields against the unseen stressors of field deployments—like humidity-induced offsets or surge transients—delivering the calibrated clarity that aligns raw analog data with logical imperatives, where every processed value fortifies against inefficiencies or interlocks that could cascade into production halts, ensuring your automation backbone endures with the precision that turns potential variances into vigilant vigilance.

- CTI-2501

- CTI-2501

The CTI -2501 functions as a balanced preprocessor in the 2500 Series PLC’s I/O layer, sliding into a standard base slot to condition 8 differential inputs—sourced from transducers or potentiometers—with onboard multiplexers that sample at up to 20 Hz per channel, applying software-configurable scaling (e.g., 4-20 mA to engineering units) and filtering before outputting to the backplane bus for CPU access like the 2500-C400 processor. The 4 outputs drive loads up to 20 mA with 12-bit DACs for proportional valves or drives, isolated at 500 V to prevent ground loops, while broken-wire detection on inputs outputs fault codes for immediate alarming. In a complete system, it interfaces with remote base controllers (RBCs) via the I/O bus for distributed architectures, supporting up to 112 modules in Profibus networks.

Positioned flexibly in the stack, the CTI -2501 excels in mixed I/O schemes, often paired with digital modules for hybrid racks where it handles analog subsets without backplane overloads, embracing redundancy through duplicate slots for 1oo2 voting on critical channels with <5 ms sync. It communicates via the PLC’s proprietary bus, with diagnostics via status LEDs (green for active, red for faults) and bit-mapped registers queryable in ladder logic for SCADA overlays. No external supplies needed; it sips 5 VDC at 300 mA max, with hot-swap compatibility for maintenance without scans halting, a boon in 24/7 process control. Protocols like Modbus can extend it via coprocessors, but in 2500 cores, it leverages the base’s inherent fault tolerance for seamless handoffs to HMIs.

This equilibrated efficiency scales intuitively—stack in bases for 64+ analog points in expansive PLC networks—while its 1-slot footprint eases legacy swaps. For the engineer plotting process power-ups, the CTI -2501 is the astute analogist that anticipates input infidelities, ensuring your mixed measures meld with modular mastery, bridging transducer truths to control clarity without the cacophony of compromises or the cost of channel chaos.

| Specification | Details |

|---|---|

| Model Number | -2501 |

| Brand | CTI (Control Technology Inc.) |

| Type | 8-Input/4-Output Analog Module |

| Input Voltage | 5 VDC (backplane) |

| Operating Temp Range | -10 °C to +60 °C |

| Mounting Style | 2500 Series Base Slot |

| Dimensions | 25.4 x 228.6 x 127 mm (H x W x D) |

| Weight | 0.3 kg |

| Interface/Bus | 2500 Series I/O Bus |

| Compliance | IEC 61131, CE, UL 508 |

| Supported Protocols | Modbus (via coprocessor) |

| Typical Power Draw | 300 mA @ 5 VDC |

Embracing the CTI -2501 infuses your 2500 Series PLC with a hybrid harmony that harmonizes diverse signals into dependable data streams, where its differential inputs filter noise that skews lesser modules, ensuring long-term performance through 12-bit fidelity that sustains ±0.1% accuracy over 100,000 hours—garnering MTBF exceeding 200,000 hours to slenderize spares in control cabinets. This endurance spares routine recalibrations, with broken-wire alerts that surface faults via PLC bits, streamlining upkeep from exhaustive extractions to expedient evals that reclaim shifts from signal sagas.

Consistency prevails in variability: 20 Hz sampling seizes 1 mA transients during ramp-ups, aligning outputs with scan cycles to forestall loop lags in dosing controls, crucial for batch safeguards where hesitation hazards homogeneity. Integration eases the load; its pin-compatible bus meshes with Simatic 505 bases sans rewires, hastening hybrid infusions and reallocating acumen from wiring woes to workflow wisdom, while output isolation adapts to valve variances without adders. Engineered for the PLC pioneer’s prudence, the CTI -2501 envisions escalations—like Ethernet coprocessors for IIoT—yielding a module that elevates not just inputs but insights, compressing TCO via fewer slots, candid cascades, and the quiet quotient that lets analogs amplify accurately, not ambiguously.

In water treatment clarifiers, the CTI -2501 conditions pH and flow analogs alongside digital levels, multiplexing signals amid chemical mists in process control crucibles, where its isolation upholds critical system uptime against pump surges, fine-tuning flocculants for clarity peaks without turbidity spikes.

Manufacturing injection molders harness the CTI -2501 for pressure inputs and solenoid outputs, amplifying data in resin-vapor realms and 5 g quakes, bolstering shot cycles in high-reliability presses that necessitate SIL 2 surety to avert overpacks during production peaks.

Power distribution feeders deploy it for voltage profiling and relay signaling, interfacing transducers in humid substations, with the CTI -2501‘s noise rejection ensuring nonstop metering by muting false drifts in continuous loads that sync with SCADA for grid-grade stability.

2502 – 16-input analog-only variant for sensor-dense monitoring in data acquisition panels.

2558 – Complementary 8-output analog module for expanded actuation in valve clusters.

2562 – Isolated high-density sibling for noisy environments like motor control centers.

2500-C400 – Paired PLC CPU for processing -2501 data in compact 2500 Series racks.

2500P-ACP1 – Coprocessor add-on for Ethernet extensions on -2501 I/O in IIoT upgrades.

2599 – Digital output counterpart for relay-heavy setups complementing -2501 analogs.

2500 Series Base – Enclosure for modular -2501 cascades in remote I/O drops.

Workbench IDE – Programming tool for ladder config and scaling of -2501 channels.

When preparing to slot the CTI -2501 into your 2500 base, first confirm base power budget—300 mA per module caps at 10 slots—and align PLC firmware to v1.27+ via CTI’s site to embed scaling functions; test input loops for <200 Ω resistance with a DMM to rule out attenuation ghosts. Torque standoffs to 1 Nm for 5 g resilience, and validate 500 V isolation between channels with a megger, while scripting 40 mm slot gaps for airflow in enclosures nearing 60 °C. Ground the base to PE per UL 508, and precondition with a dry-run calibration to affirm <20 Hz polls sans saturation.

In ongoing care, adopt a streamlined routine calibrated to process pulses. Monthly, scan status LEDs—greens for gated goods, reds for anomalies—and query PLC registers for range drifts over 0.2%, retuning scales if variances vault 1%. Quarterly, simulate faults with a loop calibrator at 12 mA, timing responses under 50 ms for IEC 61131 logs, and inspect terminals for oxide in humid vaults—dab with isopropyl, depowered to discharge dynamics. For dusty or corrosive dens, examine seals semiannually for breaches, meggering at 500 VDC to hold 10 MΩ, and echo configs on a bench base pre-patch for channel cohesion. This measured march, attuned to analog amplitudes, empowers your ops to nurture the CTI -2501‘s nuance, staving off entropy before it skews your safeguards.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626