Description

The CPCI-8211 is a high-density analog and digital I/O data acquisition module, serving as a critical interface between field sensors and the processing core in CPCI-based systems. It fits into 3U CPCI chassis, leveraging the standard’s robust mechanical design to withstand harsh operating conditions while ensuring stable communication with the system’s main processor via the CPCI backplane.

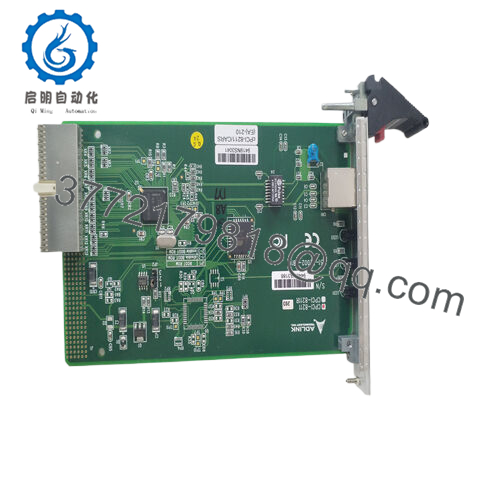

CPCI-8211

In terms of system interaction, the CPCI-8211 features 32 analog input channels (16-bit resolution) and 16 digital I/O lines, capable of simultaneous sampling at rates up to 1 MS/s per channel. This allows it to capture correlated data from multiple sensors—such as strain gauges, thermocouples, and accelerometers—without time skew. It integrates with CPCI processors like the CPCI-3840AH by transmitting acquired data over the CPCI bus, supporting both programmed I/O and direct memory access (DMA) for efficient data transfer. A standout feature is its on-board signal conditioning, including programmable gain and filtering, which reduces noise and eliminates the need for external signal Conditioning hardware. It also includes automatic calibration circuitry that minimizes drift, ensuring long-term measurement accuracy without frequent manual adjustments.

Technical specifications:

Model NumberCPCI-8211

Type 3U CPCI Analog/Digital Data Acquisition Module

Input Voltage +5V DC (from CPCI backplane)

Operating Temp Range -40°C to +70°C

Mounting Style 3U CPCI slot (PICMG 2.0 compliant)

Dimensions 160mm x 100mm (3U form factor)

Weight 520g

Interface/Bus 32-bit CPCI bus, front-panel D-sub connectors for I/O

Compliance CE, RoHS, ISO 9001

Supported Protocols CPCI bus protocols, compatible with standard CPCI software APIs

Typical Power Draw 18W (under full load)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

Main features and advantages:

Application areas:

The CPCI-8211 excels in applications requiring high-channel data acquisition in challenging environments. In automotive testing, it’s used in durability test rigs, monitoring hundreds of sensors on vehicle frames, engines, and suspension systems as they undergo simulated road conditions—its rugged design ensures accurate data even with constant vibration. In aerospace research, it captures data from wind tunnel experiments, measuring pressure distributions and airflow velocities with high precision to validate aerodynamic models. In industrial process monitoring, it tracks multiple analog variables in chemical plants, such as reactor temperature, pressure, and fluid flow, providing real-time data to the control system to maintain optimal process conditions.

Related products:

- CPCI-8210 – Lower-channel variant with 16 analog inputs, ideal for smaller-scale testing applications.

- CPCI-8212 – Higher-resolution model (24-bit) for ultra-precision measurements in research labs.

- CPCI-8211D – Version with isolated analog inputs to prevent ground loops in noisy industrial environments.

- CPCI-8220 – Digital I/O focused module with 64 digital channels, complementing the CPCI-8211 in mixed-signal setups.

- CPCIe-8211 – PCI Express-based variant for higher data transfer rates in modern CPCIe chassis.

- CPCI-8211-TC – Specialized version with built-in thermocouple cold-junction compensation for temperature-focused applications.

- CPCI-8200 – Legacy model with similar form factor, suitable for replacement in older systems.

Installation and maintenance:

REXROTH 4DMC160

GE 350-E-P1-G1-H-E-S-C-P-SN-D-N

Woodward 9907-135

ABB 216EA62

Emerson NTM-212-CBNS-0000

PROSOFT 5302-MBP-MCM4

AMAT SD1024F-2-S

KONGSBERG AKM32S-ASSNS-05

ABB 216EA62

ABB 216EA62

ABB 216EA62 1MRB150083R1/F

Emerson A6370D

DEIF PPU/2/GS

DELEM DM-103VA

ABB 216MB66 HESG324510M1

ABB 216NG62A HESG441634R1/K HESG216876

ABB 216NG63A HESG441635R1 HESG216879/K

ABB 216V62a HESG324442R13/B

ABB 216VC62a HESG324442R112/F

Baikale 8MSA3X.R0-30

WOODWARD 9907-014

WOODWARD 8440-2165

B&R 8MSA3X.R0-30

Emerson CE3007

ABB 216VC62a HESG324442R112/F

REXROTH HDS02.2-W040N-HS32-01-FW

Eaton XV-230-57CNN-1-13-1

WOODWARD 8405-094

ABB 216VC62a HESG324442R112/F

WOODWARD SPM-D2-10 8440-2066A

Eaton XV-440-10TVB-1-50

OMNI 6000-1D-1SE-1A-2SV

ABB 216VC62a HESG324442R13/B

ABB 216VC62A HESG324442R112/F

NI SBRIO-9627

Renishaw RLU10-A3-A3

BENTLY 3500/65-01-00 145988-02

WARNER MCS2000-ECA

WARNER MCS2000-DRV2

MECS CS-1000A

A-B 80026-529-01-R

ABB 216VC62A HESG324442R13

GE 5266222-2 – GSCB GOC6.6

LAM 810-135227-010

LAM 810-240888-002

LAM 810-107813-306

yokogawa ALP111-S001

Eaton XVH-340-57CAN-1-50

ABB 216VC62A HESG324442R13

Emerson A6125 9199-00069

Emerson A6210 9199-00003

ABB 216VC62A HESG324442R13

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626