Description

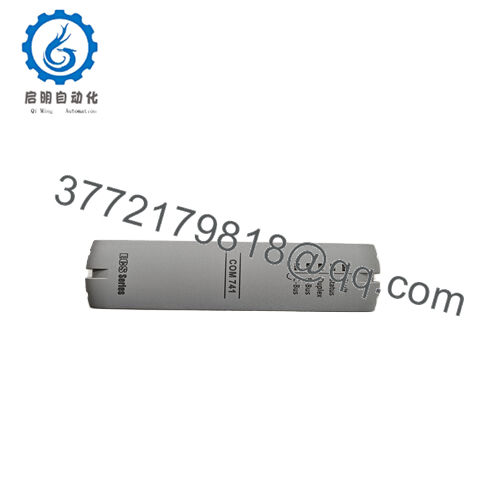

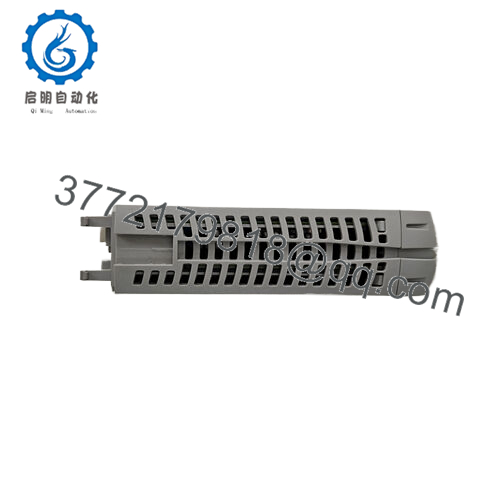

Product Model: COM741-S01

Product Brand: Supcon / YDL

Product Series / Platform: COM741 series (Control / Interface module)

Product Features:

- Embedded control / interface module for process automation

- Multiple communications: RS-232, RS-485, Ethernet (as listed by Supcon module ads)

- Memory capacity (32 MB Flash, 2 MB SRAM) per supplier advertisement

- Robust industrial design with wide operating temperature, compact footprint

Applications & Industry Context

In many industrial automation systems, controllers, I/O modules, and field devices need an intermediate interface or control card to manage communication, logic, and data exchange. The COM741-S01 module plays that role in Supcon / YDL ecosystems, serving as a bridge between field-level signals and higher-level process control systems.

You’ll often see COM741-S01 used in process plants, chemical, power, or refining systems where Supcon automation platforms are deployed. It can act as a local controller, protocol translator, or communication gateway—managing field device data and routing it upward to SCADA, DCS, or historian layers.

Because many existing systems use Supcon or YDL modules, having a compatible interface card like the COM741-S01 is valuable for retrofits, expansions, or spares stocking. Rather than redesigning entire subsystems, you can insert or replace just the interface modules to maintain compatibility with legacy architectures.

- COM741-S01

Technical Features & Benefits

Given the publicly listed parameters and typical design practices, here are plausible features and advantages of COM741-S01:

- Communications versatility

According to a Supcon product listing, the module supports RS-232, RS-485, and Ethernet interfaces. This lets it link to serial field devices, networked controllers, or supervisory systems. - Memory & processing

One supplier advertises the module has 32 MB Flash and 2 MB SRAM, giving it capacity for moderate logic, buffering, or data logging tasks. - Industrial robustness

The COM741-S01 is marketed as a “Smart Process Control Module” designed for industrial automation use cases. Its mechanical and environmental design should reflect that (e.g. extended temperature, shielded I/O). - Compact packaging / modular format

Suppliers show dimensions typical of module cards (around 90 × 84 × 44 mm) in one listing. - This compact design allows for integration into control cabinets or module racks.

- Plug-and-play / configuration utility

While not publicly confirmed, modules of this class usually support parameter upload/download, firmware updates over network, and local diagnostics. The “smart” labeling suggests some internal logic intelligence.

Technical Specifications

Below is a best-effort table based on public listings and typical design assumptions. Use this as a guide—not as final engineering specification.

| Specification | Description / Claimed Value |

|---|---|

| Model / Part | COM741-S01 (Supcon) |

| Type / Role | Smart control / communication interface module |

| Memory | 32 MB Flash, 2 MB SRAM |

| Communications Interfaces | RS-232, RS-485, Ethernet |

| Operating Temperature | –20 °C to +55 °C (one listing) |

| Power Supply Voltage | DC 24V (as per listing) |

| Dimensions | 90 mm × 84 mm × 44 mm (approx) |

| Weight | ~250 g |

| Logic / Control Capability | Embedded logic, possibly local control, data buffering |

| Environmental / Industrial Suitability | Designed for industrial / automation environments (dust, temperature) |

Installation & Maintenance Insights

To deploy COM741-S01 effectively, here are practical recommendations and caveats from experience in industrial module integration:

- Power supply stability – The module likely runs from 24 V DC. Ensure the supply is clean, well-regulated, and appropriately fused.

- Signal wiring – Use shielded twisted-pair cables for RS-485 and Ethernet. Ground shields at one end only to avoid ground loops.

- Connector validation – Ensure that all connectors (I/O, serial, network) are keyed and properly secured. Loose connectors are a common source of intermittent errors.

- Diagnostics and LED indicators – After power-up, verify module health LEDs, port status indicators, and any fault flags. Use those to quickly diagnose miswiring or communication issues.

- Firmware / configuration backup – Before installation, store the module’s firmware version and configuration (e.g. IP addresses, serial port settings). That lets you quickly swap in a replacement if needed.

- Scheduled testing – Periodically test communication integrity, error rates, and throughput. In control systems, even small communication drops can lead to data inconsistency.

- Spare unit compatibility – If stocking a spare COM741-S01, match model revision, firmware, and calibration. That reduces surprises when swapping in the field.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626