Description

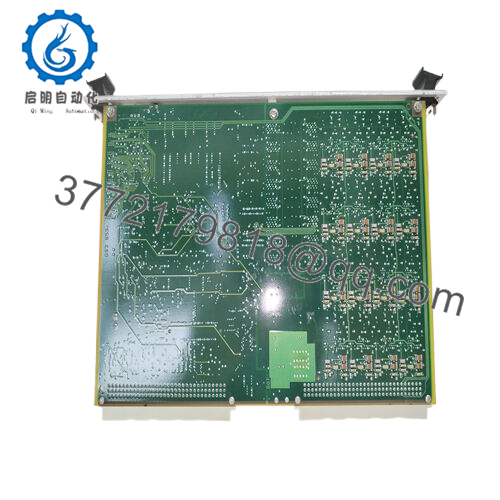

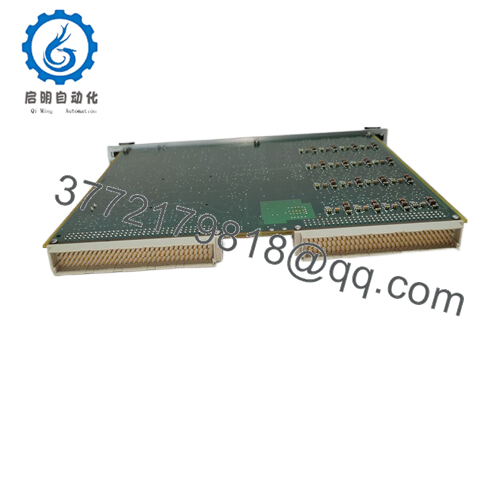

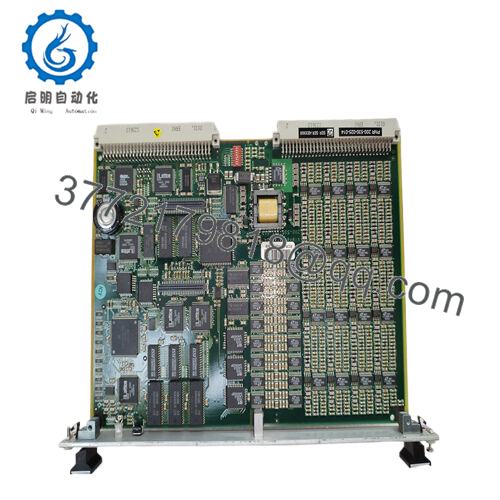

The CMC16 functions as a high-performance motion control card, designed to translate digital commands from PLCs or industrial PCs into precise motor movements for Servo and stepper motors. It supports up to 16 independent axes, with each axis capable of executing complex motion profiles – including point-to-point positioning, linear/circular interpolation, and electronic gearing – via a 32-bit floating point DSP processor

CMC16

What distinguishes it is its advanced S-curve acceleration/deceleration algorithm, which minimizes mechanical stress by smoothing velocity transitions, reducing vibration in high-speed applications like PCB drilling machines. The control card features a dual-port Ethernet interface (1000BASE-T) for real-time communication with host systems, supporting protocols such as Modbus TCP and PROFINET for integration with factory networks. It also includes 16-bit analog inputs for encoder feedback (up to 5MHz) and digital I/O for limit switches and emergency stops, ensuring closed-loop precision. The CMC16 is housed in a rugged aluminum casing with an IP20 rating, designed for PCIe slot mounting in industrial PCs, with a wide operating temperature range (-10°C to 60°C) ensuring reliability in harsh factory environments.

CMC16

Technical specifications:

Model Number CMC16

Brand GoogolTech

Type Multi-Axis Motion Control Card

Axis Count Up to 16 axes (servo/stepper compatible)

Processor 32-bit floating-point DSP

Motion Modes Point-to-point, linear interpolation, circular interpolation, electronic gearing Position Resolution

Up to 0.1μm (depending on encoder/motor)

Max Output Frequency 2MHz (pulse/direction), 10V analog (for servo drives)

Feedback Support Incremental encoders (up to 5MHz), absolute encoders (via SSI)

Communication Interfaces 2 x Gigabit Ethernet (Modbus TCP, PROFINET), 1 x RS-485

Digital I/O 32 inputs/32 outputs (isolated)

Operating Temp Range -10°C to 60°C (14°F to 140°F)

Mounting Style PCIe 3.0 x4 slot

Dimensions 165mm x 110mm (6.5″ x 4.3″)

Weight 280g (9.9oz)

Protection Features Overvoltage protection, short-circuit isolation

Compliance CE, UL 61010-1, RoHS

Software Support C/C++ libraries, PLCopen-compliant function blocks

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

CMC16

Main features and advantages:

Choosing the CMC16 delivers transformative benefits for precision manufacturing. Its 16-axis capacity eliminates the need for multiple control cards in complex systems, reducing cabinet space by up to 40% and simplifying wiring. The S-curve motion algorithm cuts cycle times by 15% in pick-and-place applications by enabling faster acceleration without mechanical stress, extending equipment lifespan. Engineers will appreciate the flexible motor compatibility—supporting both servo and stepper motors—allowing mixed use in a single system (e.g., high-precision servo axes for cutting, cost-effective steppers for material handling). The CMC16’s real-time Ethernet connectivity enables sub-millisecond synchronization between axes, critical for applications like 3D printing where layer alignment depends on perfect timing. Most importantly, its open software architecture simplifies custom programming, with PLCopen-compliant libraries reducing development time for complex motion sequences.

Application areas:

The CMC16 excels in applications demanding multi-axis precision. In aerospace component machining, it synchronizes 5 axes of a CNC mill, ensuring complex turbine blade contours are cut to within ±2μm tolerance—critical for aerodynamic performance. In electronics manufacturing, it controls 8-axis placement machines, coordinating nozzle movement with vision systems to place 01005-sized components (0.4mm x 0.2mm) accurately on circuit boards. The card also performs reliably in robotic welding cells, synchronizing 6 axes of robotic arm motion with weld current timing, ensuring consistent bead formation in automotive chassis assembly. In each scenario, the CMC16 delivers the synchronized, precise motion needed to maintain quality and throughput.

Related products:

Other product models:

REXROTH R901254695 VT-HNC100-2-3X/N-I-00/000

GE HE693THM666

Triconex 3009

Triconex 3624

Schneider PMC-2/11/04/001/00/03/10/00/10

FIREEYE 95DSS2-1

Tmeic ARND-3110N

smc INR-244-264

GE IC697CPM790

GE IC754VGF15CTD

MacGregor 2141357-804

MacGregor 2141232-802

LAM 839-101612-885

EMC VISATRON VN115/87

Cole Morgan 60WKS-CE240/12PB

TRICONE 3625

TRICONEX 3625

Berger Lahr EXRDM3913/50NEA

TRICONEX 3625

SAACKE HMI10-M REV215

EATON XVS-460-15MP1-1-10

Honeywell HMR2300-D21-485

KONGSBERG RCU502

KONGSBERG RDIOR420

KONGSBERG RSER200-4

KONGSBERG WCC600

GE IS220PDIAH1A

ELAU SM140-30-120-P0-45-M1-B1

GE IS220PDIAH1B

TRICONEX 3625

TRICONEX 3625

Schneider C600/10/1/1/1/00

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONE 3721

TRICONEX 3721

DANIEL DANIEL S600+

schneider XBTGT6340

A-B 1326AB-B720F-21K7-SERIESC

Schneider MICOMP139

PACIFIC SCIENTIFIC BLF2924-10-0-S-017

Rockwell 1794-APBDPV1

Rockwell SST-PB3-SLC

Rusgard LLC GE RS-FS-9001

GE PQMII-C-A

Honeywell IQView8/24

Honeywell IQVIEW4/24

GE F35-W00-VFH-F8L-H6L-M6L-PXX

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626