Description

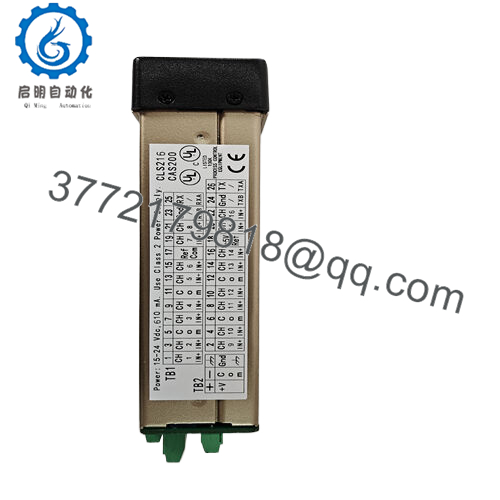

The WATLOW ANAFAZE CLS216 216-C20000DF functions as a high – performance temperature controller. It can interface with a wide variety of temperature sensors, including thermocouples and RTDs, translating the sensor data into precise control signals.

CLS216 216-C20000DF

This controller is designed to work within the overall automation stack, easily integrating with PLCs and other control platforms. It supports multiple control algorithms, with advanced PID control being a key feature. The PID control allows for fine – tuning of the temperature regulation, minimizing overshoot and undershoot. For example, it can precisely adjust the power output to a heating element or cooling system based on the difference between the setpoint and the actual temperature. It also has built – in diagnostic capabilities, constantly monitoring the sensor inputs for any signs of failure or inaccuracies. If a sensor malfunctions, the controller can quickly detect it and either switch to a redundant sensor (if available) or send out an alert to the operator. This controller can be configured to operate in stand – alone mode for simple applications or networked with other devices for more complex, integrated control systems.

CLS216 216-C20000DF

Technical specifications:

Model Number CLS216 216-C20000DF

Brand WATLOW ANAFAZE

Type Temperature Controller

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

CLS216 216-C20000DF

Main features and advantages:

Opting for the WATLOW ANAFAZE CLS216 216-C20000DF offers numerous real – world benefits. Engineered for high – precision applications, it ensures long – term performance in maintaining the desired temperature within tight tolerances. This is crucial for industries where product quality is directly linked to temperature consistency, such as the pharmaceutical and semiconductor sectors. The controller’s user – friendly configuration reduces engineering overhead. With menu – guided operation and a full – text display, setting up the controller and adjusting parameters becomes a straightforward task, even for less experienced operators. This not only saves time during the initial installation but also simplifies day – to – day operations. Additionally, its reliability means fewer unplanned downtimes due to temperature control failures. By minimizing the risk of equipment malfunctions caused by incorrect temperature regulation, it helps to keep production lines running smoothly, ultimately reducing maintenance costs and increasing overall productivity.

CLS216 216-C20000DF

Application areas:

The WATLOW ANAFAZE CLS216 216-C20000DF is widely deployed across various industries. In the food and beverage industry, it is used to control the temperature during processes like baking, brewing, and fermentation. For instance, in a brewery, precise temperature control is essential for ensuring the quality and consistency of the beer. The controller can handle the fast – changing temperature requirements during different stages of the brewing process, from mashing to fermentation, maintaining critical system uptime. In the plastics manufacturing industry, it is used to regulate the temperature of injection molding machines. The ability of the WATLOW ANAFAZE CLS216 216-C20000DF to handle high – speed data cycles and provide accurate temperature control is vital for producing plastic parts with consistent quality. In medical facilities, it can be used in equipment like incubators and sterilizers, where strict temperature control is a matter of patient safety.

CLS216 216-C20000DF

Related products:

CLS216 216-C20000DF

Installation and maintenance:

Before installing the WATLOW ANAFAZE CLS216 216-C20000DF, it’s important to check the compatibility of the sensor inputs with the controller. Ensure that the type of thermocouple or RTD you plan to use is supported. Also, verify that the communication interface of the controller is compatible with your existing control network.

Check the power supply requirements and make sure the power source can deliver stable voltage within the specified range. During ongoing maintenance, regularly check the status indicators on the controller. A normal operation is usually indicated by a steady green light, while a flashing red light may signal a fault. Periodically inspect the sensor connections for any signs of corrosion or looseness, especially in humid or dusty environments. Conduct annual calibration checks using a calibrated temperature source to ensure the controller’s accuracy remains within the specified tolerance.

Other product models:

REXROTH 4DMC160

GE 350-E-P1-G1-H-E-S-C-P-SN-D-N

Woodward 9907-135

ABB 216EA62

Emerson NTM-212-CBNS-0000

PROSOFT 5302-MBP-MCM4

AMAT SD1024F-2-S

KONGSBERG AKM32S-ASSNS-05

ABB 216EA62

ABB 216EA62

ABB 216EA62 1MRB150083R1/F

Emerson A6370D

DEIF PPU/2/GS

DELEM DM-103VA

ABB 216MB66 HESG324510M1

ABB 216NG62A HESG441634R1/K HESG216876

ABB 216NG63A HESG441635R1 HESG216879/K

ABB 216V62a HESG324442R13/B

ABB 216VC62a HESG324442R112/F

Baikale 8MSA3X.R0-30

WOODWARD 9907-014

WOODWARD 8440-2165

B&R 8MSA3X.R0-30

Emerson CE3007

ABB 216VC62a HESG324442R112/F

REXROTH HDS02.2-W040N-HS32-01-FW

Eaton XV-230-57CNN-1-13-1

WOODWARD 8405-094

ABB 216VC62a HESG324442R112/F

WOODWARD SPM-D2-10 8440-2066A

Eaton XV-440-10TVB-1-50

OMNI 6000-1D-1SE-1A-2SV

ABB 216VC62a HESG324442R13/B

ABB 216VC62A HESG324442R112/F

NI SBRIO-9627

Renishaw RLU10-A3-A3

BENTLY 3500/65-01-00 145988-02

WARNER MCS2000-ECA

WARNER MCS2000-DRV2

MECS CS-1000A

A-B 80026-529-01-R

ABB 216VC62A HESG324442R13

GE 5266222-2 – GSCB GOC6.6

LAM 810-135227-010

LAM 810-240888-002

LAM 810-107813-306

yokogawa ALP111-S001

Eaton XVH-340-57CAN-1-50

ABB 216VC62A HESG324442R13

Emerson A6125 9199-00069

Emerson A6210 9199-00003

ABB 216VC62A HESG324442R13

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626