Description

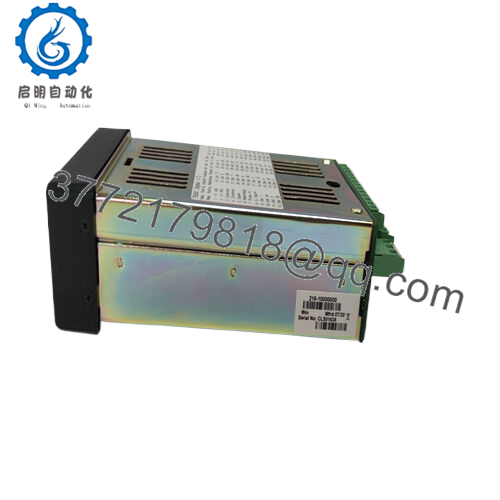

The WATLOW ANAFAZE CLS216-10000000 functions as a advanced multi-loop temperature controller, positioned at the heart of thermal management systems in the automation stack. It interfaces directly with thermocouples, RTDs, and other temperature sensors, processing input data to regulate heaters, chillers, or heat exchangers with exceptional precision. What distinguishes this model is its seamless integration with both legacy and modern control platforms: it connects via standard industrial buses to PLCs and SCADA systems, supporting real-time data transmission for centralized monitoring.

CLS216-10000000

The controller features built-in adaptive tuning algorithms that automatically adjust to changing load conditions—eliminating the need for manual recalibration during process shifts. With redundant communication ports, the WATLOW ANAFAZE CLS216-10000000 ensures uninterrupted data flow even if one connection fails, making it a reliable choice for systems where downtime is not an option. Its modular design also allows for easy expansion, accommodating additional control loops as operations scale.

CLS216-10000000

Technical specifications:

Model Number CLS216-10000000

Brand Watlow Anafaze

Type Multi-loop Temperature Controller

Input Voltage 100-240V AC, 50/60Hz

Operating Temp Range 0°C to 50°C (32°F to 122°F)

Mounting Style Panel mount with DIN rail adapter option

Dimensions 144mm x 144mm x 105mm (5.67″ x 5.67″ x 4.13″)

Weight 450g (15.9oz)

Interface/Bus Modbus RTU, Ethernet/IP, Profibus DP

Compliance CE, UL 508, RoHS, ISO 9001

Supported Protocols Modbus TCP/IP, Ethernet/IP, Profibus

Typical Power Draw 15W max

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

CLS216-10000000

Main features and advantages:

Choosing the WATLOW ANAFAZE CLS216-10000000 delivers tangible benefits that directly impact operational efficiency. Engineered for long-term performance, its rugged construction minimizes wear from constant cycling, reducing the need for premature replacements and lowering lifecycle costs. The controller’s adaptive tuning feature ensures that temperature stability is maintained even as ambient conditions or material loads change—translating to fewer process deviations and less scrap in manufacturing settings. For engineering teams, the intuitive programming interface cuts setup time significantly: pre-configured templates for common applications (like oven control or thermal profiling) reduce configuration errors and speed up deployment. Perhaps most importantly, the WATLOW ANAFAZE CLS216-10000000 provides actionable insights through its data logging capabilities, allowing operators to identify trends and optimize thermal processes over time—ultimately driving higher yields and lower energy consumption.

CLS216-10000000

Application areas:

The WATLOW ANAFAZE CLS216-10000000 thrives in industries where precise thermal control is mission-critical. In semiconductor manufacturing, it regulates the temperature of deposition chambers, ensuring uniform film growth and consistent chip performance. Pharmaceutical facilities rely on it to maintain strict temperature parameters during drug formulation and sterilization, supporting compliance with FDA and EMA guidelines. In food processing, the controller manages heating zones in pasteurization lines, balancing speed and temperature to eliminate pathogens while preserving product quality. Across all these applications, the WATLOW ANAFAZE CLS216-10000000 delivers the reliability needed for continuous uptime, even in 24/7 production environments where shutdowns are costly and disruptive. Its ability to handle rapid temperature ramps and maintain stability under varying loads makes it indispensable in process control environments where precision directly impacts bottom-line results.

CLS216-10000000

Related products:

CLS216-10000000

Installation and maintenance:

Before installing the WATLOW ANAFAZE CLS216-10000000 , confirm that the target communication bus (Ethernet/IP or Profibus) is compatible with your existing PLC firmware—updating to the latest version ensures full protocol support.

Check that the mounting panel has sufficient clearance (at least 100mm behind) for wiring and heat dissipation, as the controller generates moderate heat during continuous operation. Verify that sensor types (thermocouple vs. RTD) match the configured input channels to avoid calibration errors. Post-installation, maintenance is straightforward: weekly checks of the front-panel status indicators (green for normal operation, amber for warnings) and monthly inspections of terminal block connections to prevent loosening from vibration. Every year, a comprehensive performance calibration is run through the web interface of the controller to ensure temperature readings are within the specification range of ± 0.1 ° C – this step is crucial for maintaining long-term process consistency.

Other product models:

REXROTH 4DMC160

GE 350-E-P1-G1-H-E-S-C-P-SN-D-N

Woodward 9907-135

ABB 216EA62

Emerson NTM-212-CBNS-0000

PROSOFT 5302-MBP-MCM4

AMAT SD1024F-2-S

KONGSBERG AKM32S-ASSNS-05

ABB 216EA62

ABB 216EA62

ABB 216EA62 1MRB150083R1/F

Emerson A6370D

DEIF PPU/2/GS

DELEM DM-103VA

ABB 216MB66 HESG324510M1

ABB 216NG62A HESG441634R1/K HESG216876

ABB 216NG63A HESG441635R1 HESG216879/K

ABB 216V62a HESG324442R13/B

ABB 216VC62a HESG324442R112/F

Baikale 8MSA3X.R0-30

WOODWARD 9907-014

WOODWARD 8440-2165

B&R 8MSA3X.R0-30

Emerson CE3007

ABB 216VC62a HESG324442R112/F

REXROTH HDS02.2-W040N-HS32-01-FW

Eaton XV-230-57CNN-1-13-1

WOODWARD 8405-094

ABB 216VC62a HESG324442R112/F

WOODWARD SPM-D2-10 8440-2066A

Eaton XV-440-10TVB-1-50

OMNI 6000-1D-1SE-1A-2SV

ABB 216VC62a HESG324442R13/B

ABB 216VC62A HESG324442R112/F

NI SBRIO-9627

Renishaw RLU10-A3-A3

BENTLY 3500/65-01-00 145988-02

WARNER MCS2000-ECA

WARNER MCS2000-DRV2

MECS CS-1000A

A-B 80026-529-01-R

ABB 216VC62A HESG324442R13

GE 5266222-2 – GSCB GOC6.6

LAM 810-135227-010

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626