Description

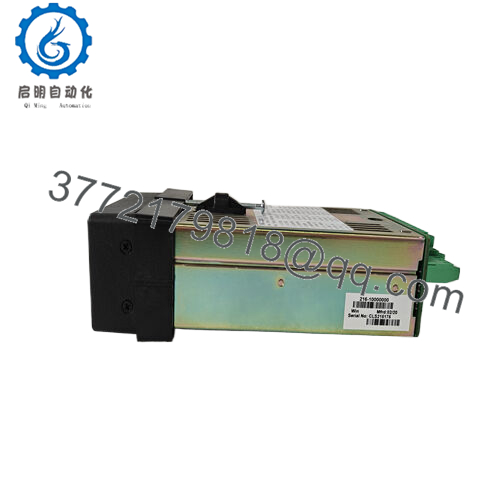

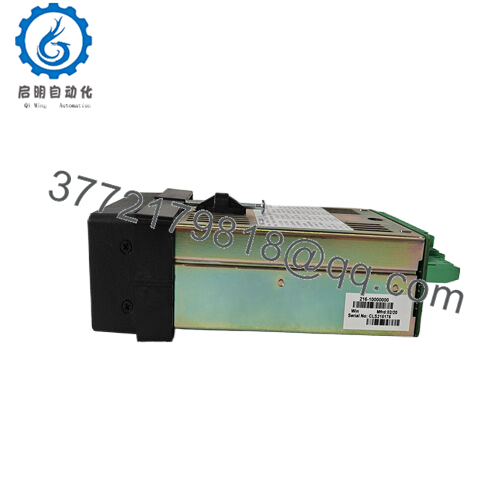

The Watlow CAS200 CLS216 is an advanced multi-loop temperature and process controller, designed to simplify and enhance control in complex industrial systems. It is especially relevant in demanding manufacturing sectors such as plastics, food processing, chemical production, and rubber extrusion, where precise control, reliable monitoring, and efficient process transitions are essential. By combining multiple control loops and integrated advanced alarm management, the CAS200 CLS216 helps operations reduce downtime, optimize throughput, and maintain consistent product quality.

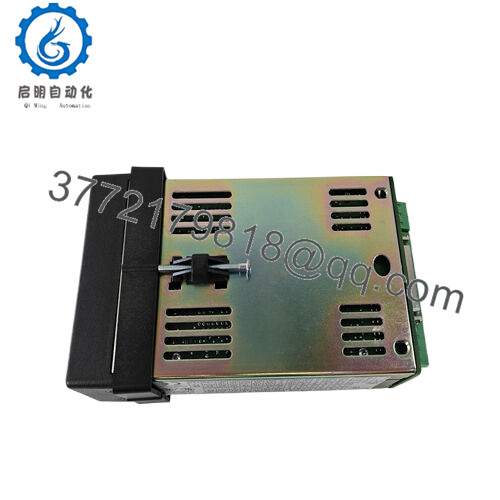

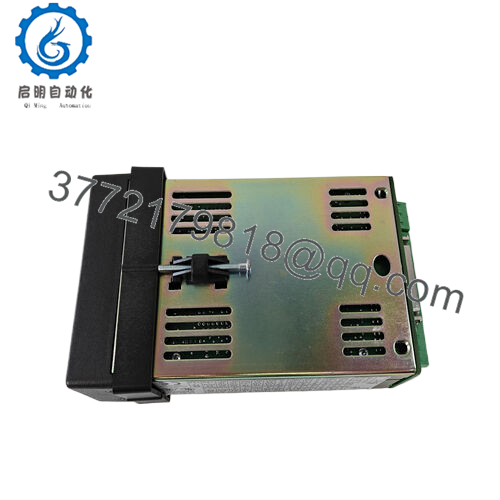

The core strength of the CAS200 CLS216 lies in consolidating up to 16 heating and cooling loops within a single controller module, maximizing panel space utilization and minimizing wiring complexity. Its sophisticated autotuning PID algorithms reduce setup time and improve process stability, even under changing load conditions. The front panel includes a full-text, menu-driven interface offering intuitive operation and rapid access to configuration settings, alarms, and diagnostics.

- CAS200 CLS216

- CAS200 CLS216

Compatible with Watlow’s extensive suite of communication protocols, including Modbus RTU and TCP, the controller integrates seamlessly into modern distributed control systems (DCS) and SCADA environments, ensuring enhanced data acquisition and process oversight. Flexibility in sensor inputs—including thermocouples, RTDs, voltage, and current signals—allows adaptation for numerous process types. Robust alarm management features enable the setting of high/low limits and deviation alarms per loop, supporting proactive fault detection and prevention.

The CAS200 CLS216 carries UL and CE certification, supports operation within typical industrial temperature ranges (0 to 55°C), and mounts within compact 1/8 DIN panels, making it suitable for retrofits and new installations alike.

| Parameter | Value |

|---|---|

| Model | CAS200 CLS216 |

| Brand | Watlow |

| Type | Multi-loop PID Process and Temperature Controller |

| Control Loops | Up to 16 loops |

| User Interface | Full-text menu with 4.3” color TFT display |

| Sensor Inputs | Thermocouple, RTD, Linear voltage/current |

| Communication Protocols | Modbus RTU, Modbus TCP, EtherNet/IP |

| Power Supply | 15 to 24 V DC |

| Operating Temperature | 0°C to 55°C |

| Alarm Features | High/Low process and deviation alerts, alarm grouping |

| Certification | UL, CE |

| Mounting | 1/8 DIN panel |

| Application | Industrial temperature/process control |

Related devices in the Watlow product line include the CLS204 (4 loops), CLS208 (8 loops), and specialized extruder firmware-enabled models of the CLS216, each targeting various application scales and control complexities.

Installation best practices cover secure DIN panel mounting with consideration for heat dissipation and noise reduction. Wiring should comply with industrial standards for signal integrity, and the controller’s firmware should be kept current for optimal performance. Regular sensor calibration and loop tuning verification help maintain process accuracy.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626